Ionic liquid grafted cellulose nanocrystal and preparation method thereof

A technology of ionic liquid and cellulose, which is applied in the field of ionic liquid-grafted cellulose nanocrystals and its preparation, can solve the problems that ionic liquids cannot be grafted in the form of covalent bonds, and achieve improved redispersibility and durability Improved thermal performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

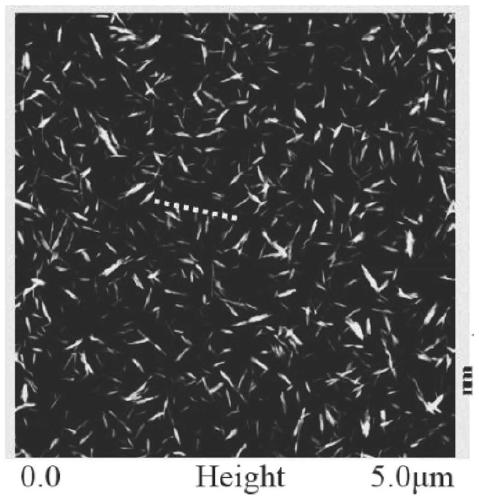

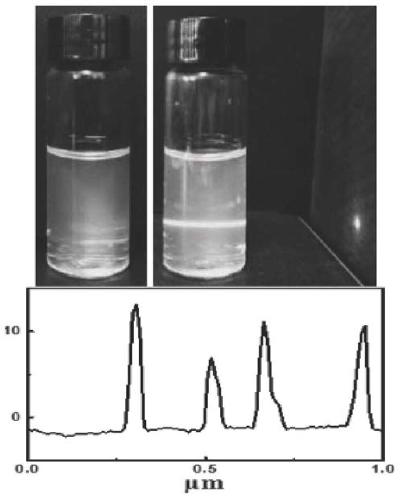

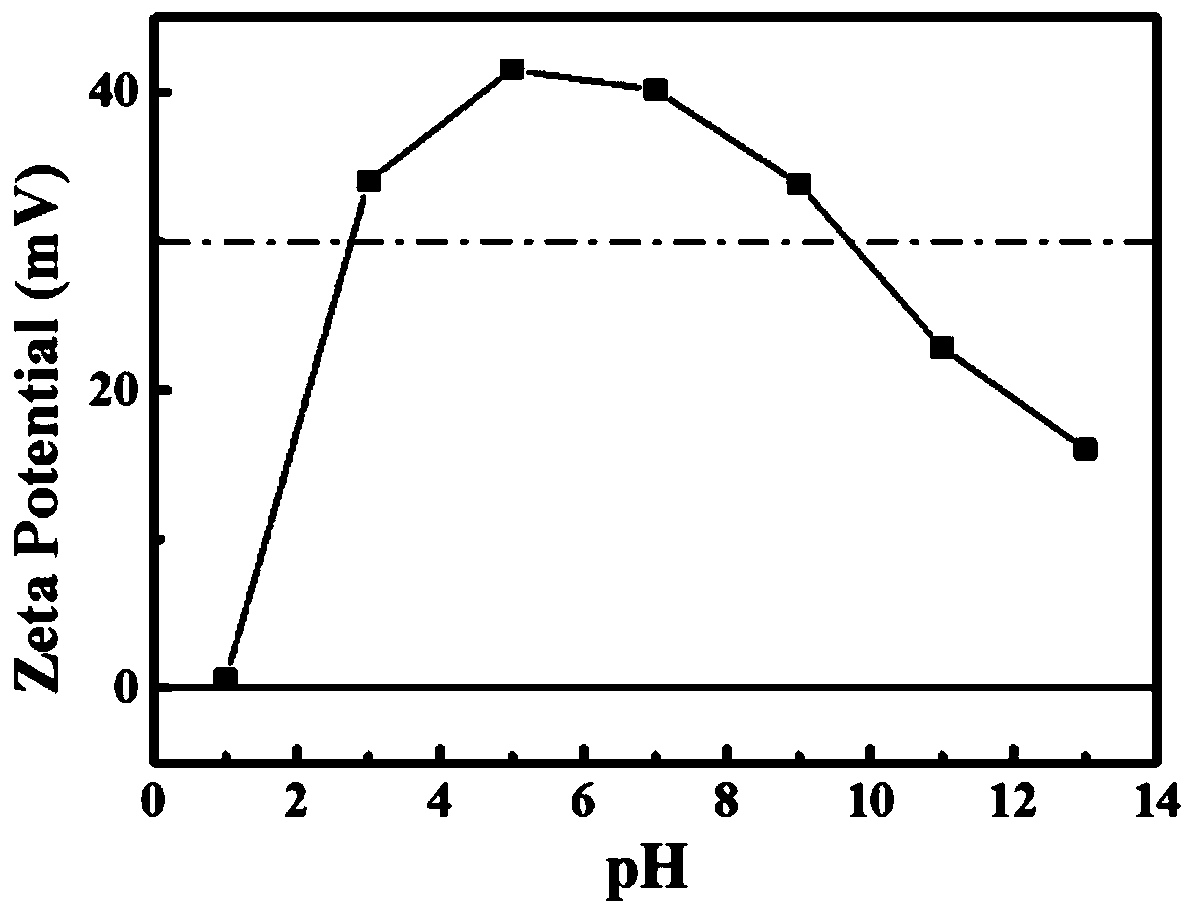

[0046] 20 mL of 2% sulfonated cellulose nanocrystal suspension at pH=7 was added to a one-necked flask, and 5 mg of zinc acetate and 5 g of lactic acid monomer were added after ultrasonication. Place the single-necked flask in a water bath at room temperature until the temperature reaches 180°C and keep it for 10 minutes, add cold water to stop the reaction, and then centrifuge repeatedly to obtain cellulose nanocrystals modified by lactic acid monomers; disperse them into a three-necked flask filled with 8 mL of deionized water Add 5g of 1-vinyl-3-butylimidazolium tetrafluoroborate ([VBIm][BF 4 ]), ultrasonically added 50mg of azobisisobutyronitrile / methanol solution 2mL, fully stirred and reacted at 70°C for 24h, the product was washed and dried to obtain a white or light yellow solid. [VBIm][BF 4 ] The degree of substitution on the surface of the cellulose nanocrystal is 34%, and the Zeta potential of the resulting cellulose nanocrystal is 52mv.

[0047] The photo of the ...

Embodiment 2

[0049] Selected raw material type and technological process are with embodiment 1, and difference is [VBIm] [BF 4 ] is 8g, the Zeta potential value of the resulting cellulose nanocrystal is 45mv, and the ionic liquid [VBIm][BF 4 ] The degree of substitution on the surface of cellulose nanocrystals is 27%.

Embodiment 3

[0051] Selected raw material type and technological process are with embodiment 1, and difference is [VBIm] [BF 4 ] is 2g, the Zeta potential value of the resulting cellulose nanocrystal is 31mv, and the ionic liquid [VBIm][BF 4 ] The degree of substitution on the surface of cellulose nanocrystals is 17%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com