Full-bio-based benzoxazine resin and preparation method thereof

A technology of benzoxazine and oxazine resin, applied in the field of materials, can solve the problems of non-environmental protection and sustainable development, achieve glass transition temperature and thermal stability improvement, natural and easy-to-obtain raw materials, and flame retardant The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of bisphenols with vanillin / p-hydroxyacetophenone type chalcone structure:

[0045]Add 13.6g of vanillin (0.1mol) and 15.3g of p-hydroxyacetophenone (0.1mol) into the reaction vessel, add 50mL of toluene to dissolve, 2mL of boron trifluoride ether as catalyst, react at 55°C for 4h, and put The reaction solution was poured into methanol / water=1:1 (v / v) mixed solution for recrystallization to obtain golden yellow crystals, which were dried to obtain bisphenol powder with chalcone structure.

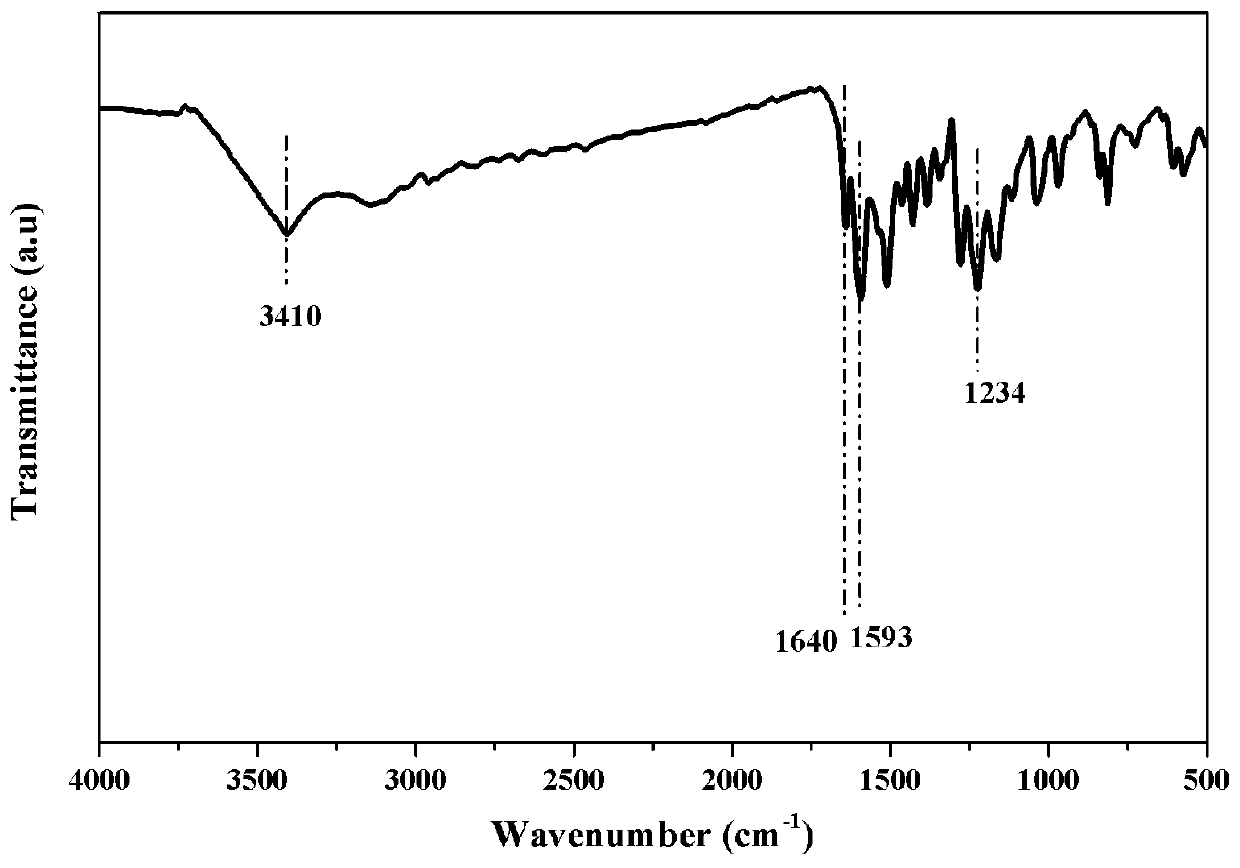

[0046] Such as figure 1 Shown is the infrared spectrogram of the vanillin / p-hydroxyacetophenone type chalcone structure bisphenol prepared in this embodiment, 3410cm -1 Represents the characteristic absorption peak of phenol-OH, 1640cm -1 Represents the characteristic absorption peak of C=O, 1593cm -1 Represents C=C, 1234cm -1 Representative-OCH 3 In summary, it shows that the synthetic product of this example is vanillin / p-hydroxyacetophenone bisphenol with chalcone...

Embodiment 2

[0048] Preparation of bisphenols with vanillin / p-hydroxyacetophenone type chalcone structure:

[0049] Add 13.6g vanillin (0.1mol) and 15.3g p-hydroxyacetophenone (0.1mol) to the reaction vessel, add 50mL toluene / ethanol (2:1v / v) mixed solution to dissolve, 2mL boron trifluoride ether as catalyst , reacted at 55°C for 4h, after the reaction was completed, the reaction solution was poured into methanol / water=1:1 (v / v) mixed solution for recrystallization to obtain golden yellow crystals, and chalcone structure bisphenol powder was obtained after drying.

Embodiment 3

[0051] Preparation of all biobased benzoxazine monomers:

[0052] Add 8.10g (0.03mol) of bisphenols with chalcone structure prepared in Example 1, 3.88g (0.04mol) of furfurylamine, and 3.60g (0.12mol) of paraformaldehyde into a mixture equipped with a condenser, a magnetic stirrer, and a thermometer. In a 250mL three-necked flask, the molar ratio of phenolic hydroxyl group, amino group and aldehyde group functional group is 6:4:12, then add 75mL of toluene solvent, mix well and heat to 115°C for 8 hours, after the reaction, pour the reaction solution into 100mL Precipitate in methanol solution to obtain a brown-yellow suspension, let it stand for 12 hours, remove the supernatant to obtain a brown-yellow precipitate, vacuum-dry the brown-yellow precipitate at 60°C for 8 hours, and finally grind the dried product to obtain a brown-yellow powder. It is a fully bio-based benzoxazine monomer.

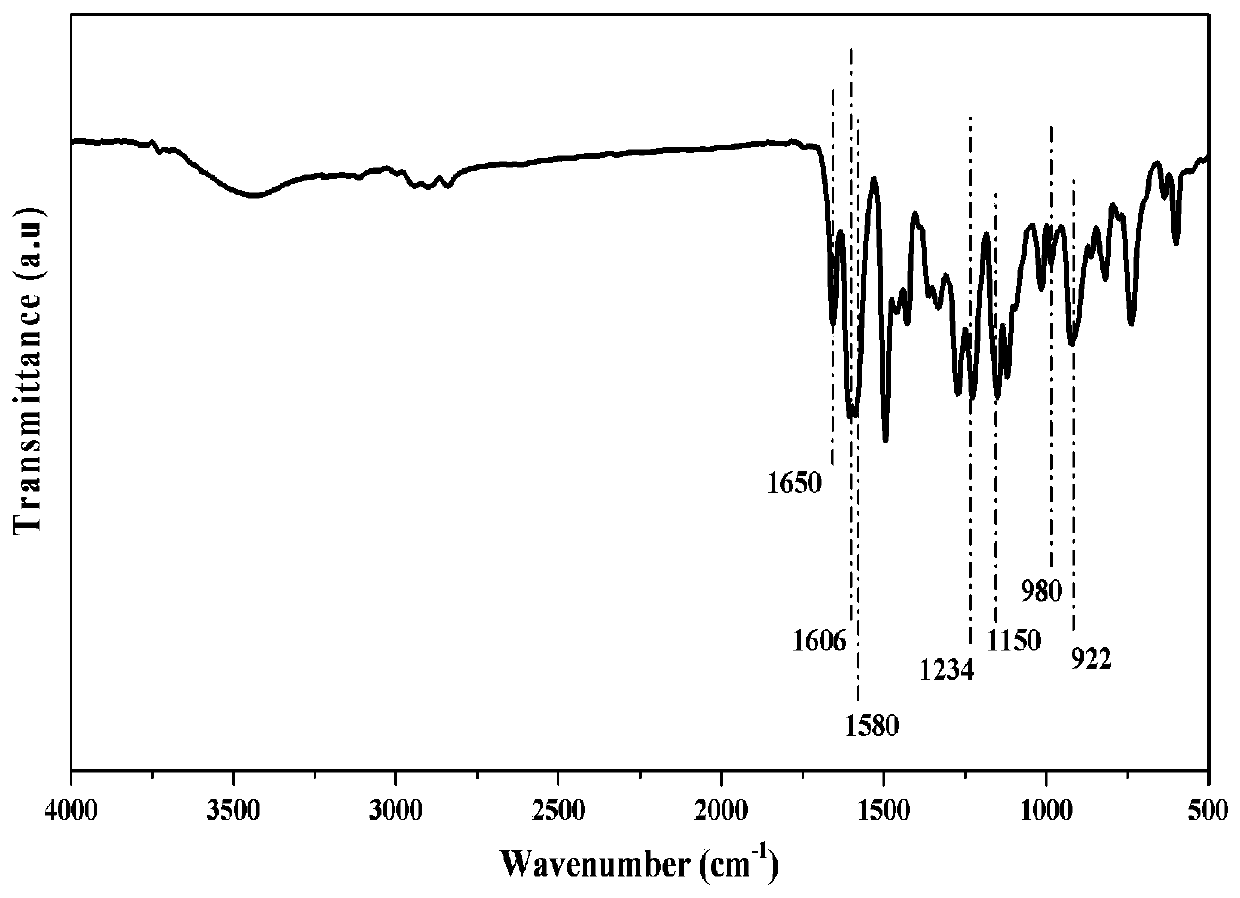

[0053] Such as figure 2 Shown is the infrared spectrogram of the whole bio-based benz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com