Preparation method for bio-based degradable polymer superfine fibers

A technology for degrading polymers and ultrafine fibers, which is applied in the field of materials, can solve problems such as unstable preparation process, poor fiber continuity, and complicated production process, and achieve the effects of simple and controllable preparation method, realizing carbon cycle, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

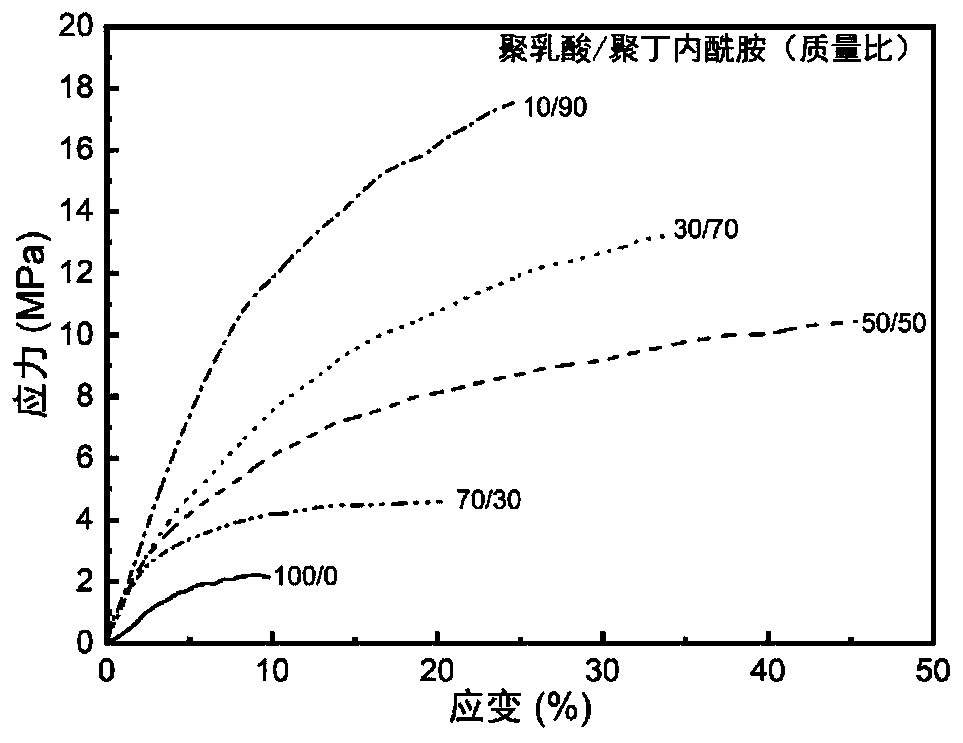

[0034] Weigh a certain amount of poly(L-lactic acid) (viscosity average molecular weight 30000) and polybutyrolactam (viscosity average molecular weight 13000) according to the mass ratio of 5 / 5, dissolve in hexafluoroisopropanol, seal and stir at room temperature More than 12 hours, until the solution is uniform and transparent, let it stand for 1 hour to remove air bubbles, and prepare a uniform spinning stock solution with a concentration of 2wt%. Electrospinning was carried out under the conditions of voltage 30kV, flow rate 1.5mL / h, and distance between spinneret and collecting plate 12cm. The obtained fibers had an average diameter of 0.65 µm. The tensile stress-strain curve of the fiber membrane is as figure 1 shown. The tensile strength of the fiber membrane is 10.4MPa, and the elongation at break is 45%.

[0035] For the convenience of comparison, pure poly(L-lactic acid) fibers were prepared under the same conditions. Compared with pure poly(L-lactic acid) fibers,...

Embodiment 2

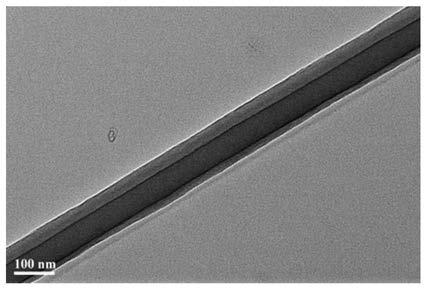

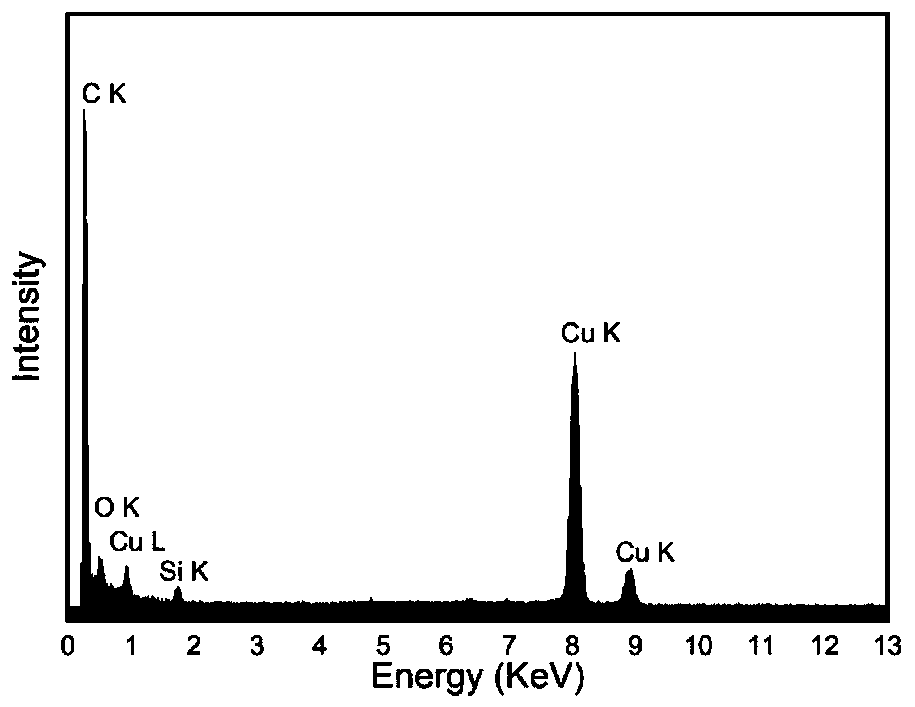

[0037] The preparation method is the same as in Example 1, except that the mass ratio of poly(L-lactic acid) to polybutyrolactam is 7 / 3, the solution concentration is 5wt%, the solution flow rate is 1mL / h, the spinneret and the collecting device The distance is 20cm. The obtained fibers had an average diameter of 0.69 µm. The tensile strength of the fiber membrane is 4.9MPa, and the elongation at break is 21%. The transmission electron micrographs of the obtained fibers are as follows: figure 2 As shown, it has a clear core-shell structure. Further adopt X-ray Energy Spectroscopy (EDS), such as image 3 As shown, it indicates that the shell layer is polylactic acid.

Embodiment 3

[0039] The preparation method is the same as in Example 1, except that the mass ratio of poly(L-lactic acid) to polybutyrolactam is 3 / 7, and the spinning voltage is 25kV. The obtained fibers had an average diameter of 0.59 µm. The tensile strength of the fiber membrane is 13.8MPa, and the elongation at break is 36%, which are respectively 5.6 times and 2.7 times higher than that of pure poly(L-lactic acid) fibers prepared under the same conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com