High-voltage lithium ion battery combined electrolyte additive, electrolyte and battery thereof

A lithium-ion battery pack and electrolyte additive technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problem of increasing battery polarization and impedance, deterioration of battery electrochemical performance, and increased polarization and other problems, to achieve the effect of reducing impedance, adding a small amount, and reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of combined electrolyte for high-voltage lithium-ion batteries:

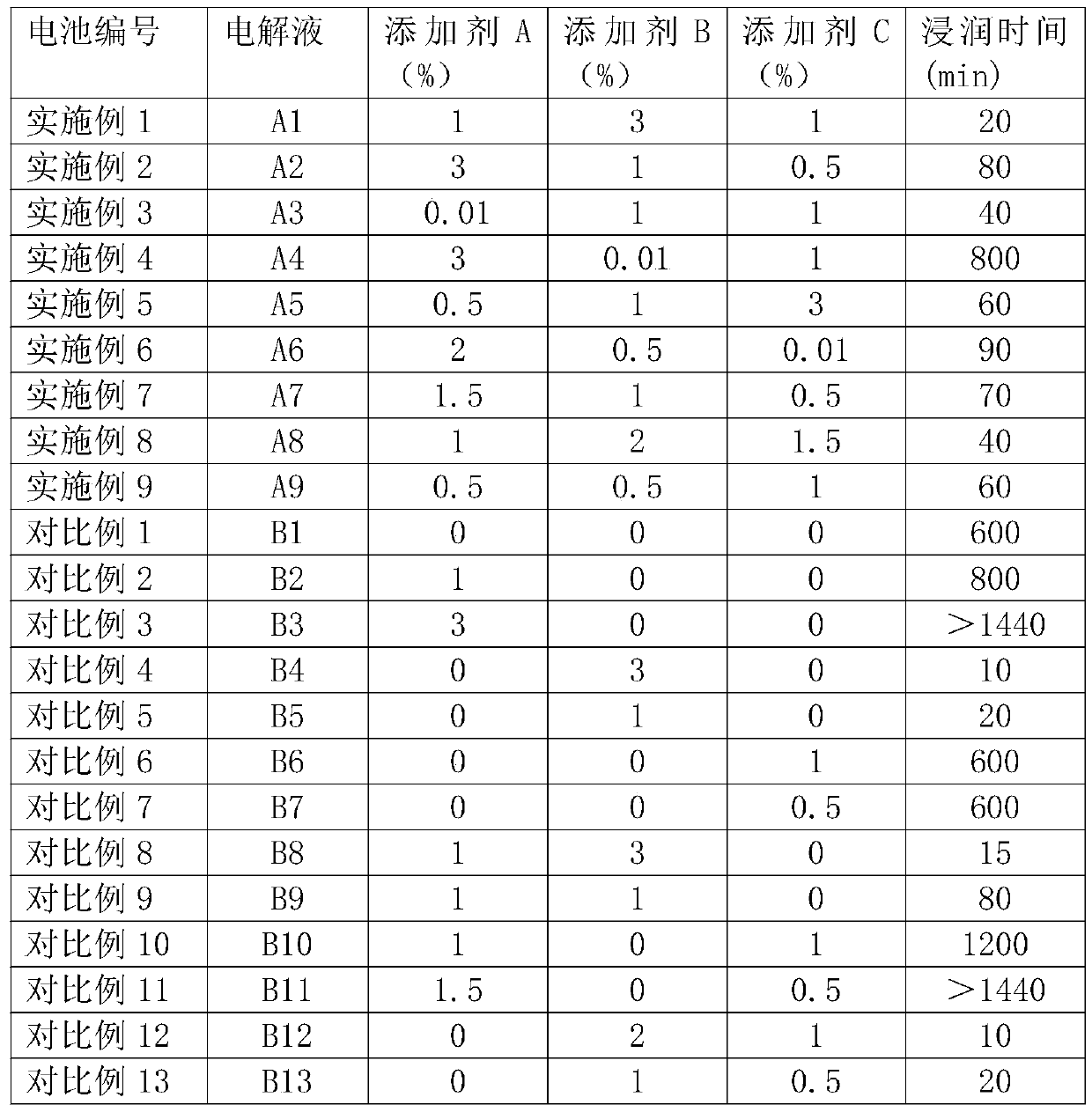

[0022] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the combined electrolyte solution A1 for a high-voltage lithium-ion battery. Drop 0.2ml of A1 electrolyte onto the surface of the positive electrode sheet, seal it with a sealed box, and observe the complete soaking time of the electrolyte.

[0023] Preparation of high-voltage lithium-ion batteries:

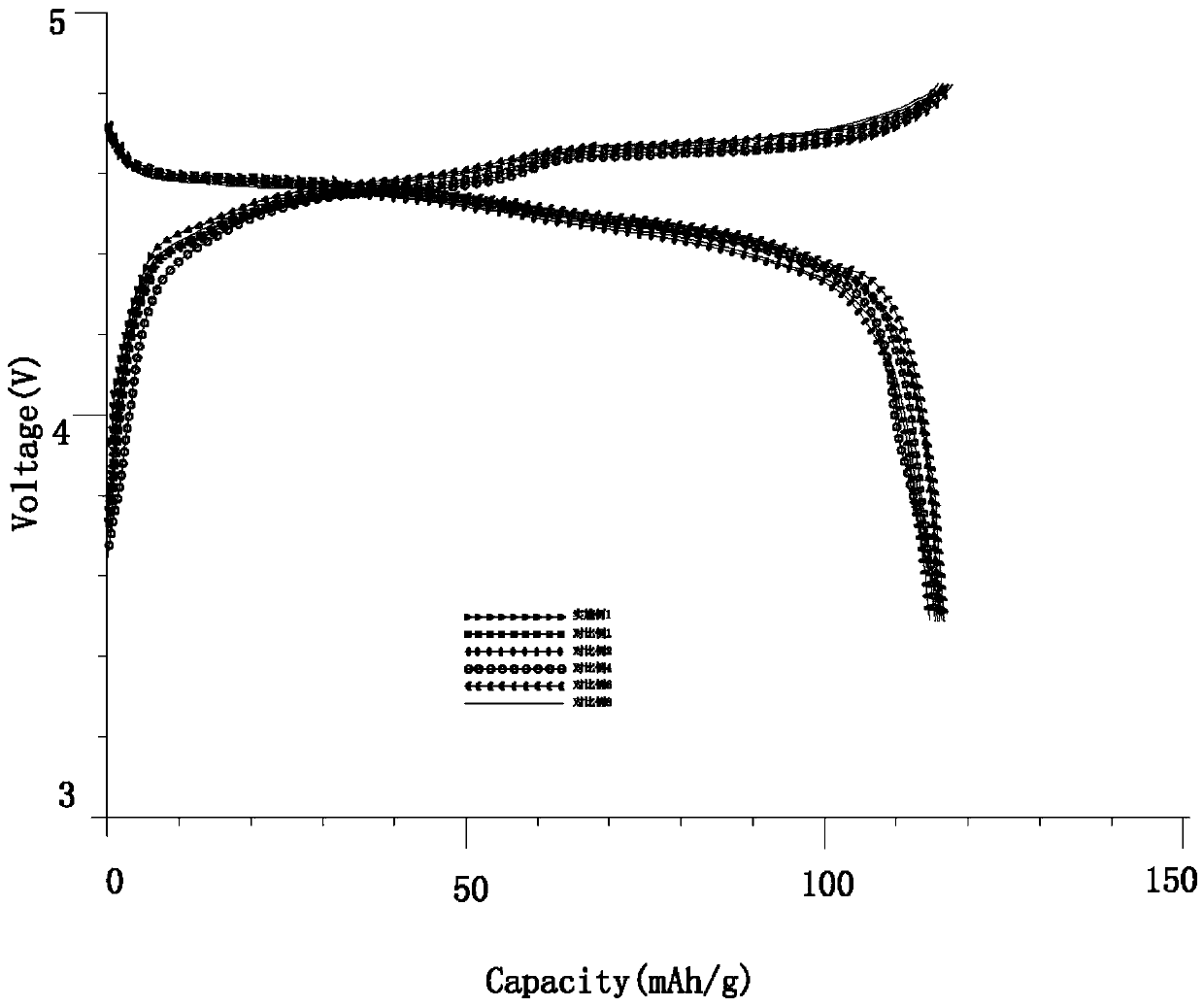

[0024] Will LiNi 0.5 mn 1.5 o 4(LNMO) is used as the positive electrode active material, carbon black is used as the conductive additive, and carboxymethyl cellulose (CMC), styrene-butadiene copolymer (SBR) is used as the binder, and the mass ratio is 92:5:1 :2 After mixing evenly in water, coat the aluminum foil current collector, dry, cold press, cut into discs with a diameter of φ14mm, and place them in the glove box. Graphite is used as the negative electrode active material, car...

Embodiment 2

[0026] Its difference from Example 1 is the preparation of high-voltage lithium-ion battery combined electrolyte:

[0027] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain a combined electrolyte solution A2 for a high-voltage lithium-ion battery. Drop 0.2ml of A2 electrolyte onto the surface of the positive electrode, seal it with a sealed box, and observe the time for the electrolyte to fully infiltrate.

Embodiment 3

[0029] Its difference from Example 1 is the preparation of high-voltage lithium-ion battery combined electrolyte:

[0030] In a glove box filled with argon (moisture 6 , and stirred until it was completely dissolved to obtain the combined electrolyte solution A3 for a high-voltage lithium-ion battery. Drop 0.2ml of A3 electrolyte onto the surface of the positive electrode sheet, seal it with a sealed box, and observe the complete soaking time of the electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com