Preparation method of porous niobium nitride powder microwave absorption material

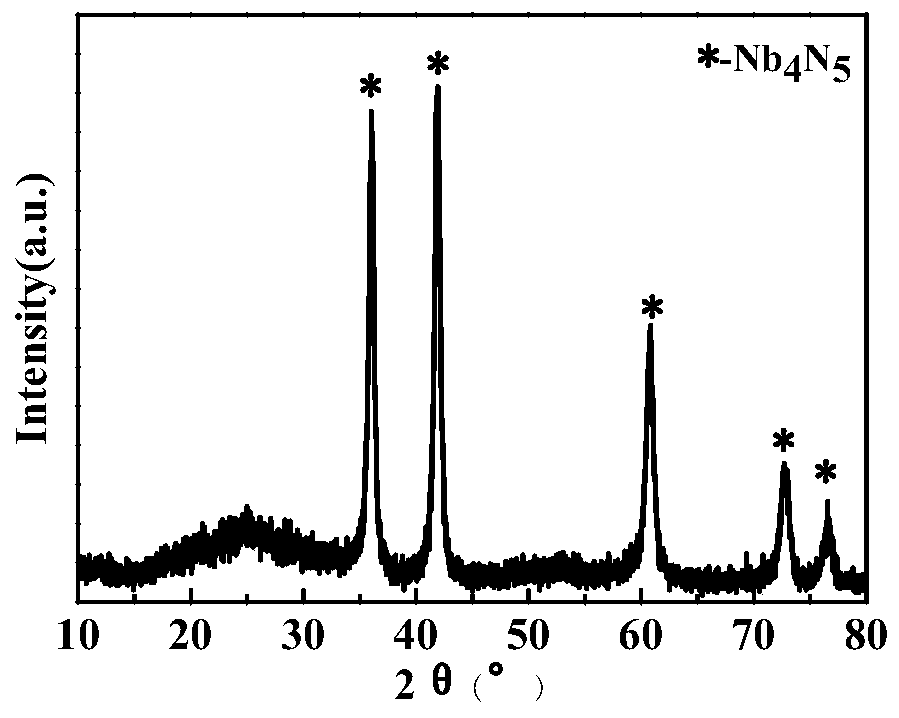

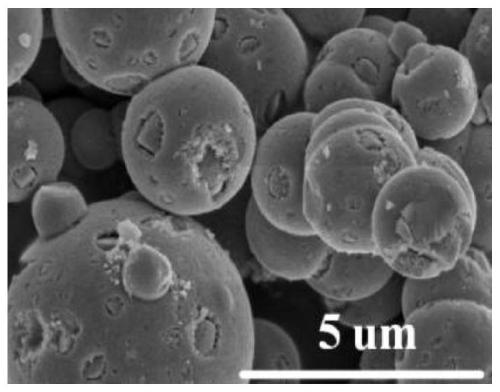

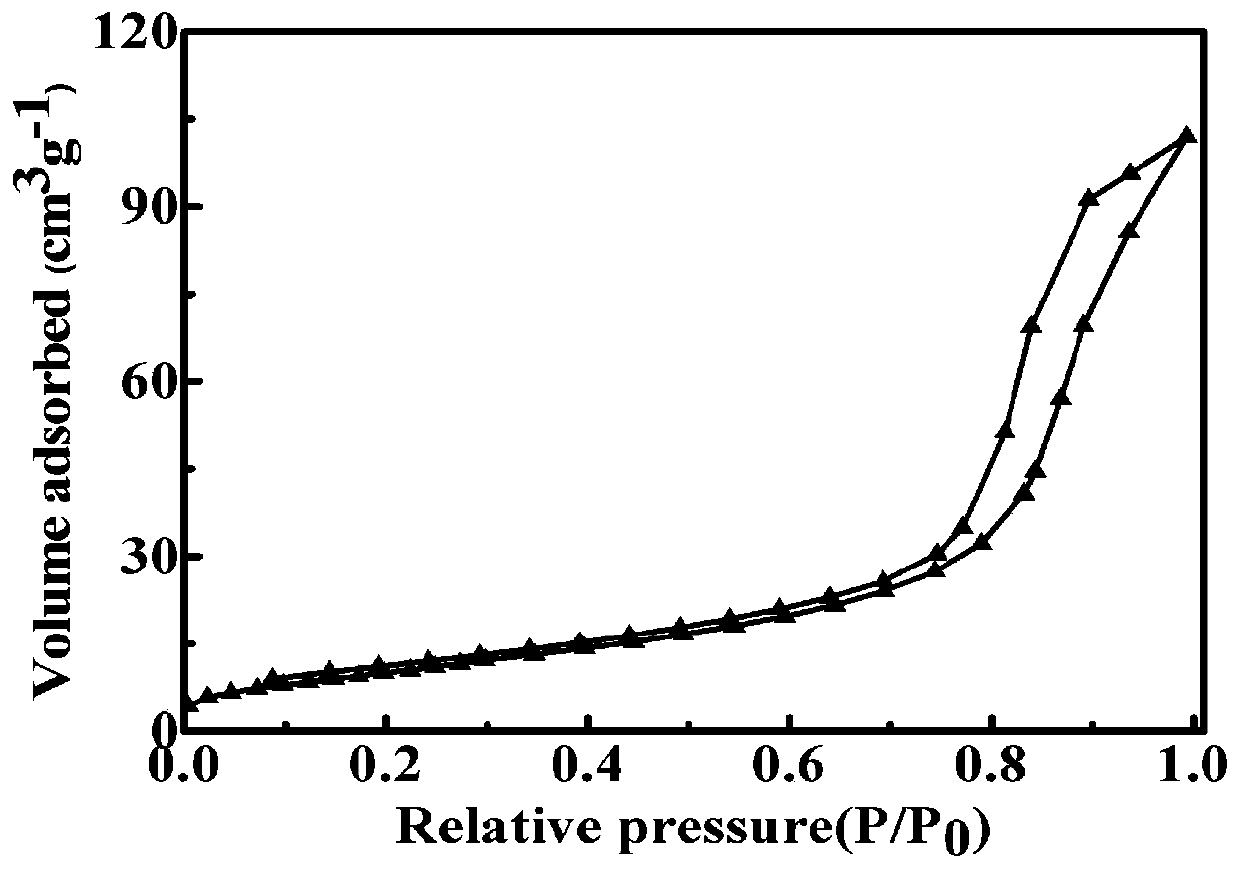

A technology of microwave absorbing materials and niobium nitride, which is applied in the field of material science, can solve problems such as light weight and high efficiency of microwave absorbing materials, insufficient pore structure, and high powder density, and achieve excellent microwave absorption characteristics and good crystallinity , the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 1.35g of niobium pentachloride, add 1.5mL of absolute ethanol and 0.2g of P123, then add 30mL of dichloromethane to obtain a mixed solution, transfer the mixed solution into the reaction bomb, and keep it in an oven at 110°C for 38h. After taking out the sample, wash it with dichloromethane for 3 times, then let it stand for 30 minutes, pour off the supernatant, and dry it in a drying oven at 80°C for 24 hours to obtain the niobium oxide xerogel, and pre-calcine the niobium oxide xerogel at 400°C , the heating rate was 1° C. / min, and the temperature was kept for 30 minutes to obtain niobium oxide powder. Weigh 8g of niobium oxide powder and 1.7g of cyanamide in 10mL of absolute ethanol and stir evenly, then keep warm in a drying oven at 80°C for 24h, and reduce the dried mixed powder to nitrogen at 800°C in flowing ammonia After 2h, a porous niobium nitride powder was obtained. During the nitriding process, when the temperature rises to 300°C, feed 400ml / min of a...

Embodiment 2

[0030] Weigh 1.5g of niobium pentachloride, add 1.2mL of absolute ethanol and 0.3g of P123, then add 30mL of dichloromethane to obtain a mixed solution, transfer the mixed solution into the reaction bomb, and keep it in an oven at 100°C for 42h. After taking out the sample, wash it with dichloromethane for 3 times, then let it stand for 30 minutes, pour off the supernatant, and dry it in a drying oven at 80°C for 24 hours to obtain the niobium oxide xerogel, and pre-calcine the niobium oxide xerogel at 400°C , the heating rate was 1° C. / min, and the temperature was kept for 30 minutes to obtain niobium oxide powder. Weigh 8g of niobium oxide powder and 2g of cyanamide, put them in 10mL of absolute ethanol and stir evenly, then keep them in an oven at 80°C for 24 hours, and then reduce and nitride the dried mixed powder at 900°C in flowing ammonia 2h to obtain porous niobium nitride powder. During the nitriding process, when the temperature rises to 300°C, feed 400ml / min of am...

Embodiment 3

[0032] Weigh 1g of niobium pentachloride, add 1mL of absolute ethanol and 0.1P123, then add 30mL of dichloromethane to obtain a mixed solution, transfer the mixed solution into the reaction bomb, and keep it in an oven at 1120°C for 24h. After taking out the sample, wash it with dichloromethane for 3 times, then let it stand for 30 minutes, pour off the supernatant, and dry it in a drying oven at 80°C for 24 hours to obtain niobium oxide xerogel, and pre-calcine the niobium oxide xerogel at 500°C , the heating rate was 1° C. / min, and the temperature was kept for 30 minutes to obtain niobium oxide powder. Weigh 7g of niobium oxide powder and 1g of cyanamide in 10mL of absolute ethanol and stir evenly, then keep warm in an 80°C drying oven for 24 hours, and then dry the mixed powder in flowing ammonia, and reduce and nitride it at 700°C 4h to obtain porous niobium nitride powder. During the nitriding process, when the temperature rises to 300°C, feed 400ml / min of ammonia gas, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com