A kind of preparation method of c/sic structure material with nearly zero expansion characteristic

A technology of structural materials and near-zero expansion, which is applied in the field of preparation of C/SiC structural materials, can solve the problems of lack of space for cushioning expansion, etc., and achieve the effects of reducing production costs, simple preparation process, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

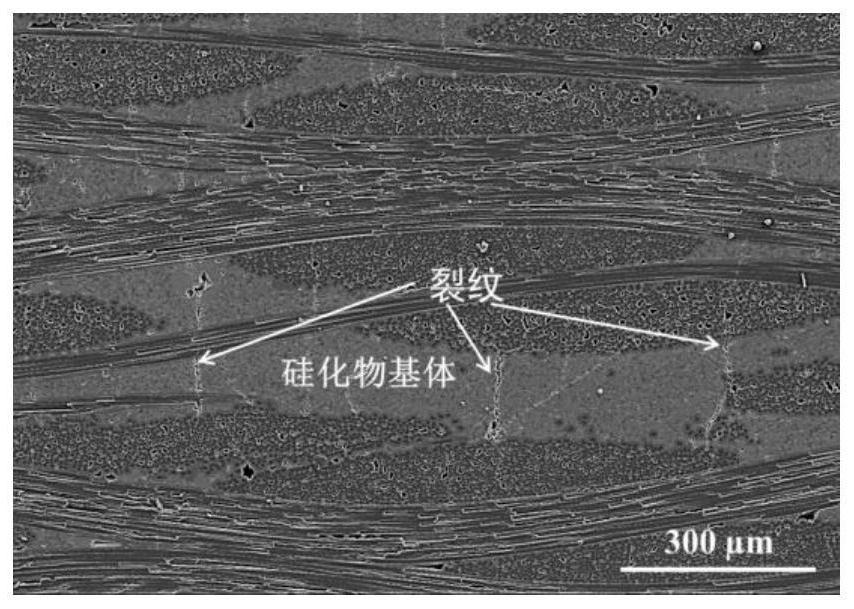

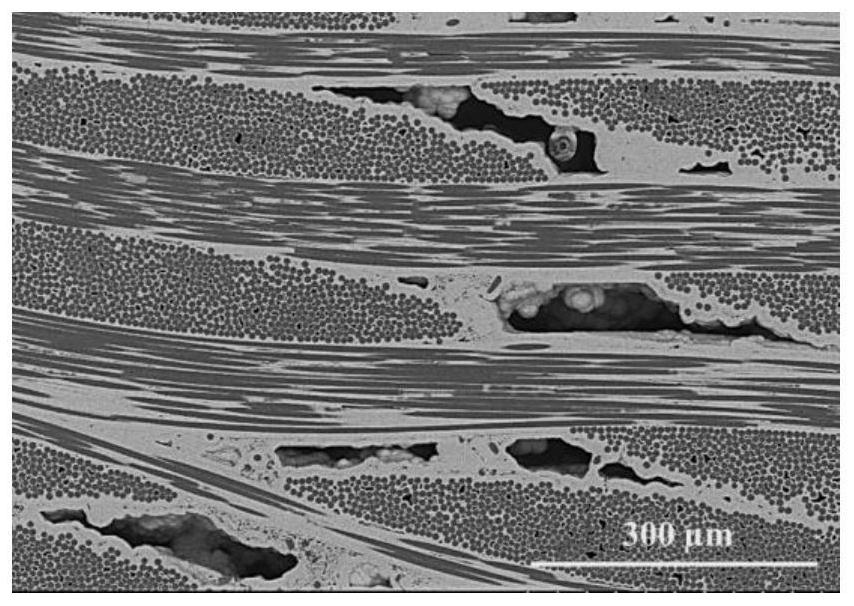

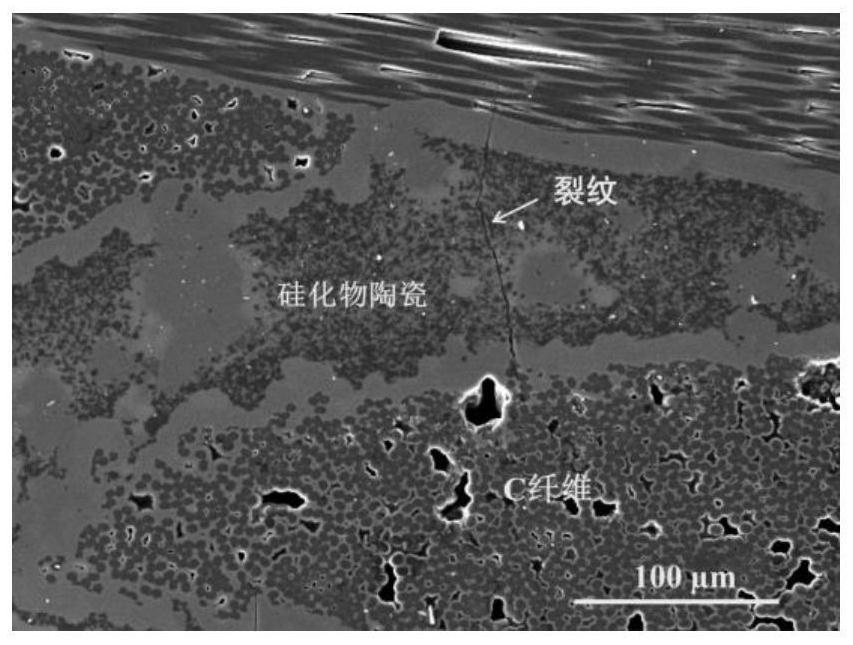

[0032] The plain carbon fiber cloth preform is used as the reinforcement, and the fiber volume content is 40%. The carbon interface phase is prepared on the surface of the preform fiber bundle by chemical vapor infiltration process and treated at high temperature. The surface of the fiber bundle is obtained. The carbon interface with a thickness of 150nm Floor. The silicon carbide substrate was prepared by chemical vapor infiltration process, the deposition temperature was 1000 °C, and the deposition time was 200 h. Then, the fiber preform is infiltrated with carbon powder by the slurry infiltration process, and the silicon carbide matrix is quickly prepared by the chemical vapor infiltration process. The melt reaction temperature is 1450 ° C and the holding time is 2 hours. Finally, a 0.1mm silicon carbide coating was prepared on the surface of the material by chemical vapor deposition process. The obtained ceramic matrix composite has a density of 2.1 g / cm 3 , the porosi...

Embodiment 2

[0034] The plain carbon fiber cloth layup preform was used as the reinforcement, and the fiber volume content was 40%. The carbon interface phase was prepared on the surface of the preform fiber bundle by chemical vapor infiltration process and treated at high temperature. The surface of the fiber bundle obtained a carbon interface with a thickness of 300 nm. Floor. The silicon carbide substrate was prepared by chemical vapor infiltration process, the deposition temperature was 1000 °C, and the deposition time was 300 h. Then, the fiber preform is infiltrated with boron carbide powder by the slurry infiltration process, and the silicide matrix is quickly prepared by the reactive melt infiltration process. The melt reaction temperature is 1500 ° C and the holding time is 60 minutes. Finally, a 0.05mm silicon carbide coating was prepared on the surface of the material by chemical vapor deposition process. The obtained ceramic matrix composite has a density of 2.2 g / cm 3 , th...

Embodiment 3

[0036] The plain carbon fiber cloth layup preform was used as the reinforcement, and the fiber volume content was 40%. The carbon interface phase was prepared on the surface of the preform fiber bundle by chemical vapor infiltration process and treated at high temperature. The surface of the fiber bundle obtained a carbon interface with a thickness of 400 nm. Floor. The silicon carbide substrate was prepared by chemical vapor infiltration process, the deposition temperature was 1000 °C, and the deposition time was 150 h. Then, the fiber preform is infiltrated with silicon carbide powder through the slurry infiltration process, and the silicide matrix is quickly prepared by the reactive melt infiltration process. The melt reaction temperature is 1600 ° C, and the holding time is 40 minutes. The CVD process is used to prepare the surface of the material. 0.1mm silicon carbide coating. The obtained ceramic matrix composite has a density of 2.3 g / cm 3 , the porosity is 7%. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com