Solid corrosion and scale inhibitor and processing method thereof

A processing method and technology of anti-scaling agent, applied in chemical instruments and methods, earthwork drilling, scale removal and water softening, etc. Predominant price, excellent scale and corrosion inhibition, good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation of the imidazoline quaternary ammonium salt in the embodiment and the comparative example includes the following steps, in the device reactor with reflux and oil-water splitter, add 350-500 parts of alkyl acid, add 40-100 parts of polyethylene polyamine 150-250 parts of xylene as a water-carrying agent, stir and heat to 160°C, keep the reaction temperature at 140-180°C, reflux for 6-10 hours, add 30-50 parts of benzyl chloride, stir and heat to 80-120°C, Reflux for 4-6 hours, then raise the temperature to 120-200°C, vacuum pressure 0.01-0.1MPa, evaporate unreacted polyethylene polyamine and xylene, and obtain imidazoline quaternary ammonium salt after cooling.

[0045] In the present embodiment, the specific parameters are set as follows. In the device reactor with reflux and oil-water separator, add 350 parts of alkanoic acid, 40 parts of polyethylene polyamine, and 150 parts of water-carrying agent xylene, stir and heat To 160°C, keep the reaction temp...

Embodiment 1

[0052] A solid slow-release antiscaling agent, comprising the following components: 300kg of imidazoline quaternary ammonium salt, 90kg of organic phosphoric acid, 20kg of bactericide, 7kg of dispersant, and 200kg of water.

[0053] The processing method of the solid slow-release antiscaling agent comprises the following steps: weighing raw materials by weight, mixing uniformly, collecting the mixture, and performing briquetting treatment, collecting the extruded product, and air-drying naturally to obtain the solid slow-release antiscaling agent . The extruded shape is a rod or a ball, preferably a rod in this document.

[0054] During the construction of the solid slow-release anti-fouling agent, prepare materials as required. Calculated on the basis that the effective concentration of corrosion inhibitor is 15mg / L and the active ingredient is 90%, per m 3 The medicament material needed for the liquid yield is 15g.

[0055] The construction process includes the following ...

Embodiment 2

[0060] The difference between embodiment 2 and embodiment 1 lies in the difference of component content.

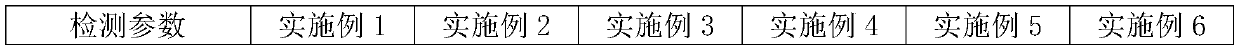

[0061] components Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 imidazoline quaternary ammonium salt 30 32 35 32 32 32 organophosphate 9 9 9 8 10 9.5 fungicide 2 2 2 2 2 2 Dispersant 0.7 0.7 0.7 0.7 0.7 0.7 water 20 25 30 25 25 25 components Example 7 Example 8 Example 9 Example 10 Example 11 Example 12 imidazoline quaternary ammonium salt 32 32 35 32 32 32 organophosphate 9 9 9 8 10 10 fungicide 1 3 2 2 2 2 Dispersant 0.7 0.7 0.5 1 0.7 0.7 water 25 25 25 25 25 25

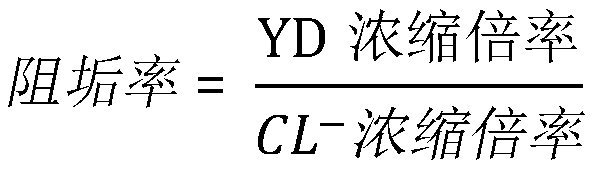

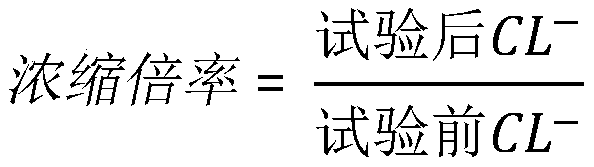

[0062] Experimental detection

[0063] 1. The appearance is required to be a light yellow or brown stick.

[0064] 2. Static corrosion inhibition rate / %: (1) After treating the metal test piece with petroleum ether and absolute ethanol with a boili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com