Nano precipitate image acquisition method based on scanning electron microscope back scattering mode

A technology of image acquisition and scanning electron microscopy, which is applied in the field of iron and steel metallurgy, can solve problems such as difficult observation, achieve the effects of reducing materials, improving utilization, and reducing the influence of magnetic fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

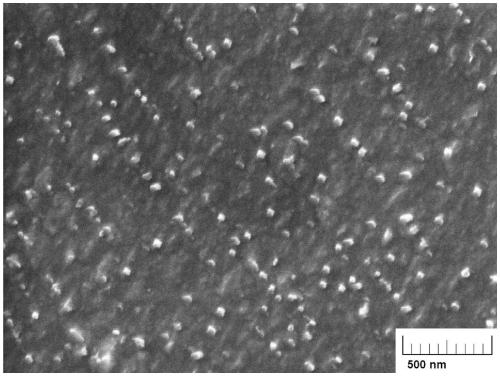

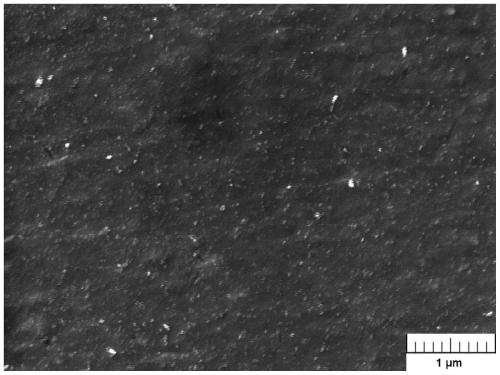

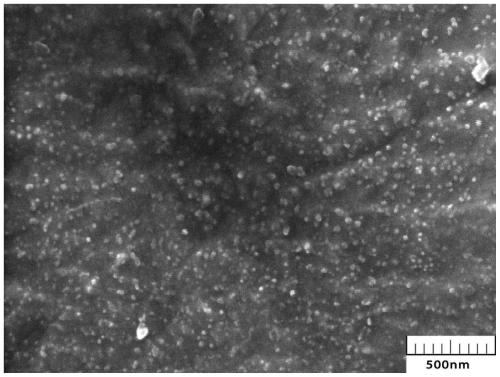

Embodiment 1

[0044] Preprocess Q460 steel into 300μm-thick sheets by wire electric discharge cutting, and use 400#, 800#, 1200#, 1500#, 2000# silicon carbide metallographic sandpaper to polish and thin it to 80μm; use a punching machine to punch it into a diameter It is a small disc of 3mm, and ground until both sides are flat; use an alcohol solution with a volume fraction of 5% perchloric acid and 2.5% glycerin at -25°C, 20V constant voltage electrolytic double-jet thinning for 60s; the sample after double-spraying Wash in absolute ethanol for 3 times, corrode with 4% nitric acid alcohol at -20°C, and then use absolute ethanol to clean, and finally dry the surface of the sample with absolute ethanol with an ear washing ball, and examine it under a scanning electron microscope. Observe the morphology of nano-scale carbides, where the scanning electron microscope acceleration voltage is 9kV, and the working distance is 8mm, such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com