Adhesive sheet for temporary fixing, and method for producing semiconductor device by using same

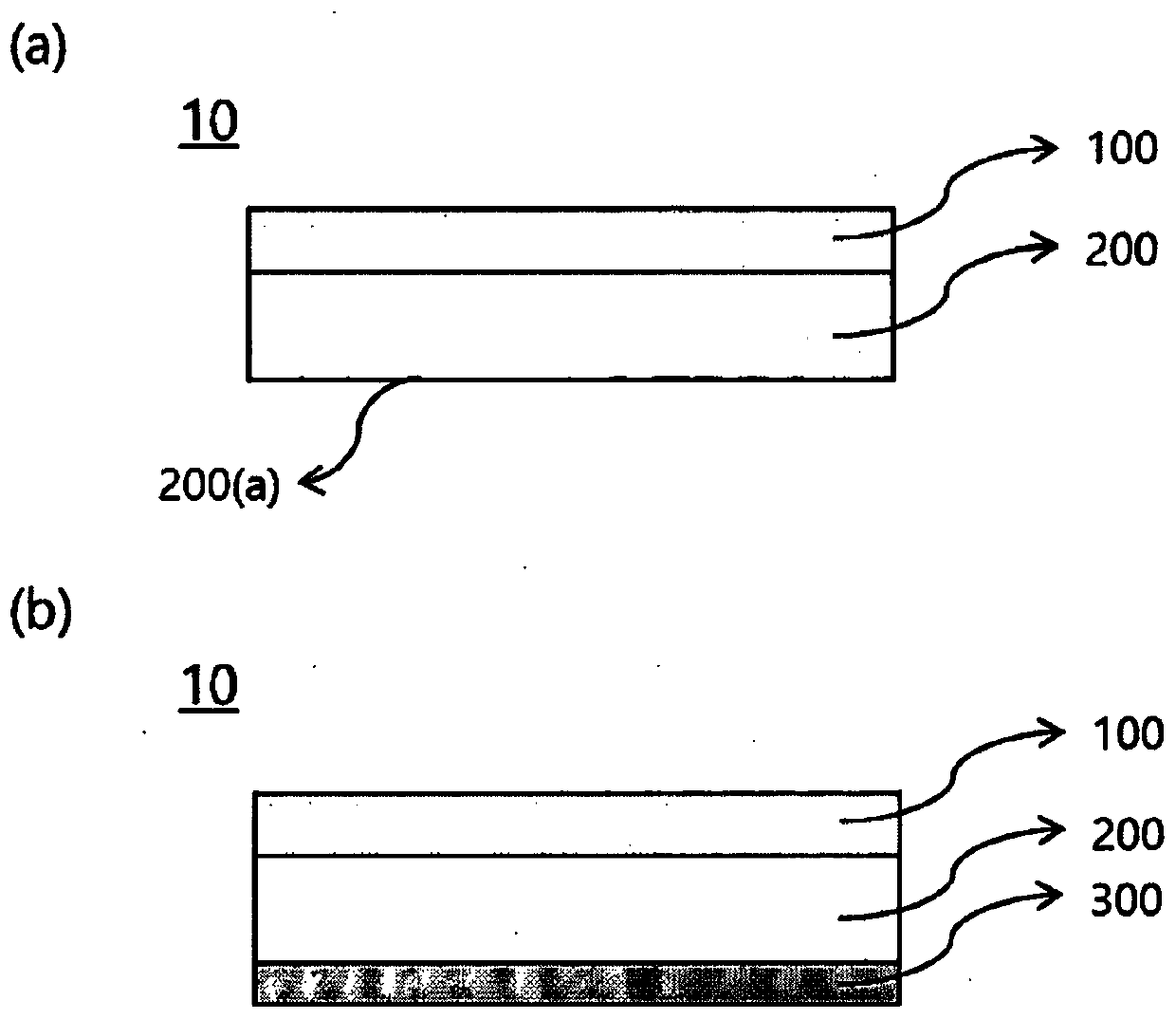

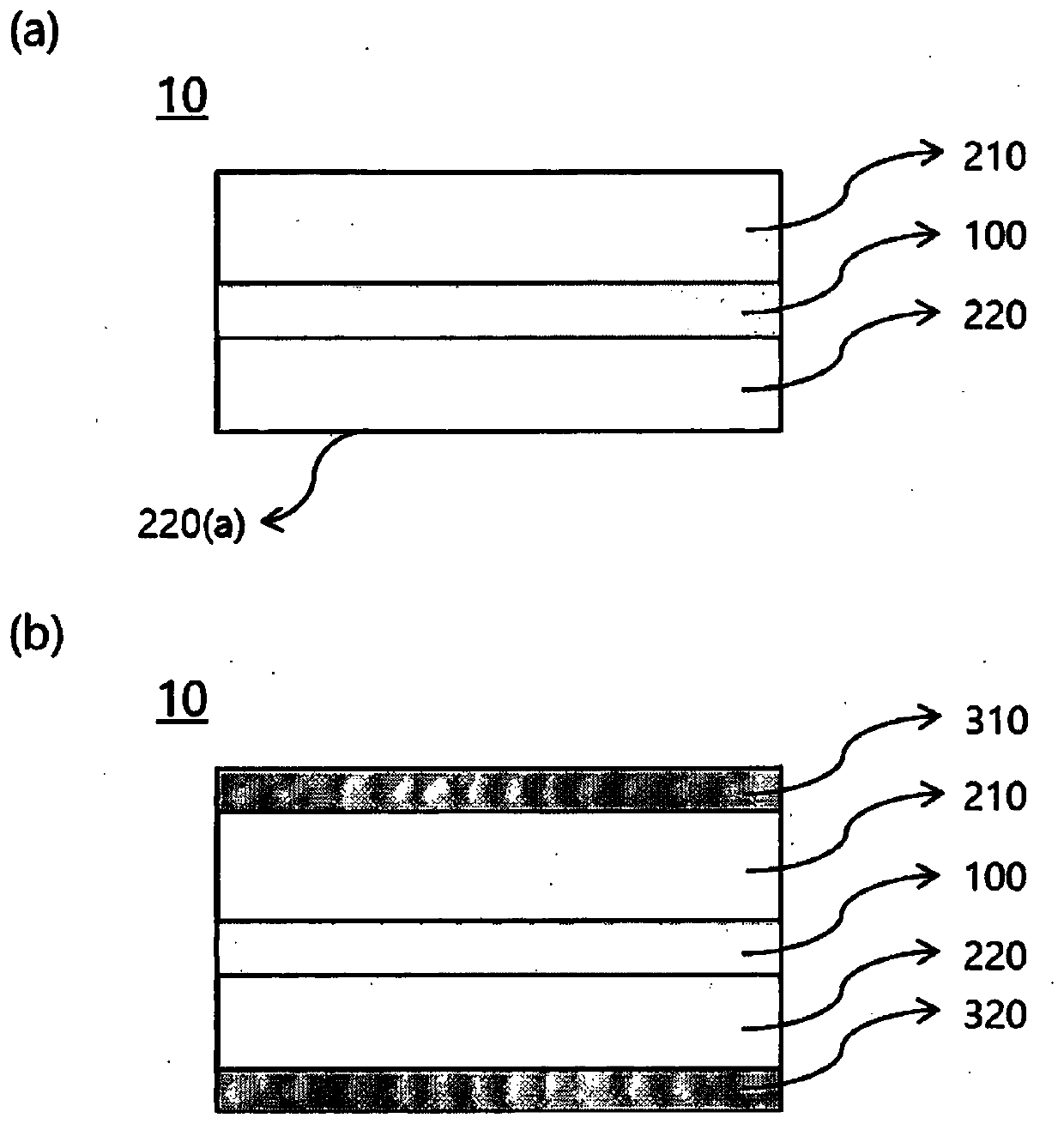

A technology for temporarily fixing and bonding sheets, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical solid-state devices, etc., and can solve problems such as reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

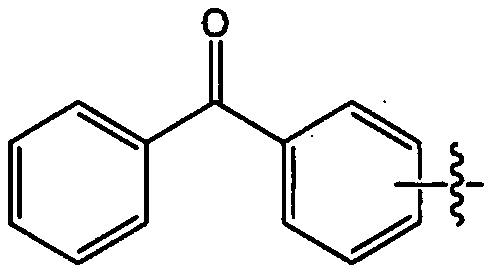

preparation example 1

[0112] A monomer mixture consisting of 75 g of 2-ethylhexyl acrylate (2-EHA), 5 g of 4-benzoylphenyl methacrylate and 20 g of hydroxyethyl acrylate (HEA) was introduced into a reactor equipped with a cooling system , to reflux under nitrogen with easy temperature control. Subsequently, based on 100 g of the monomer mixture, 400 μm of n-DDM as a chain transfer agent (CTA) and 100 g of ethyl acetate (EAc) as a solvent were added thereto, and nitrogen gas was injected to remove oxygen in the reactor at 30 Mix well for 30 minutes or more at ℃. Then, the temperature was raised and kept at 62° C., 300 ppm of V-60 (azobisisobutyronitrile) was introduced as a reaction initiator to initiate the reaction, and then allowed to polymerize for 6 hours to prepare a primary reaction product.

[0113] The primary reaction product was blended with 24 g (90 mol % relative to HEA in the primary reaction product) of 2-methacryloyloxyethyl isocyanate (MOI) and 0.24 g of catalyst (DBTDL: dibutyltin...

preparation example 2

[0116] A monomer mixture consisting of 20 g of ethyl acrylate, 63 g of 2-ethylhexyl acrylate (2-EHA), 2 g of 4-benzoylphenyl acrylate and 15 g of hydroxyethyl acrylate (HEA) was introduced into a cooling system equipped The reactor was refluxed under nitrogen and the temperature was easily controlled. Subsequently, based on 100 g of the monomer mixture, 400 μm of n-DDM (n-dodecylmercaptan) as a chain transfer agent (CTA) and 100 g of ethyl acetate (EAc) as a solvent were added thereto, and nitrogen gas was injected to remove Oxygen in the reactor while mixing thoroughly at 30 °C for 30 min or longer. Then, the temperature was raised and kept at 62° C., 300 ppm of V-60 (azobisisobutyronitrile) was introduced as a reaction initiator to initiate the reaction, and then allowed to polymerize for 6 hours to prepare a primary reaction product.

[0117] The primary reaction product was blended with 15 g (76 mol % relative to HEA in the primary reaction product) of 2-methacryloyloxyet...

preparation example 3

[0120] 100g of the (meth)acrylate binder resin (a-1) of Preparation Example 1, 4g of TDI-based isocyanate curing agent, 3g of bis(2,4,6-trimethylbenzoyl) as photoinitiator )-phenylphosphine oxide and 7 g of ethyl-p-dimethylaminobenzoate as an amine compound were mixed to prepare a composition (A-3) for forming an adhesive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com