Water-borne epoxy resin cross-linking agent, modified protein adhesive and application

A water-based epoxy resin and cross-linking agent technology, which is applied in the direction of protein adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of unfavorable practical application and poor water resistance of protein adhesives, and achieve important Economic and social benefits, solving the problem of excessive dependence, and ensuring the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

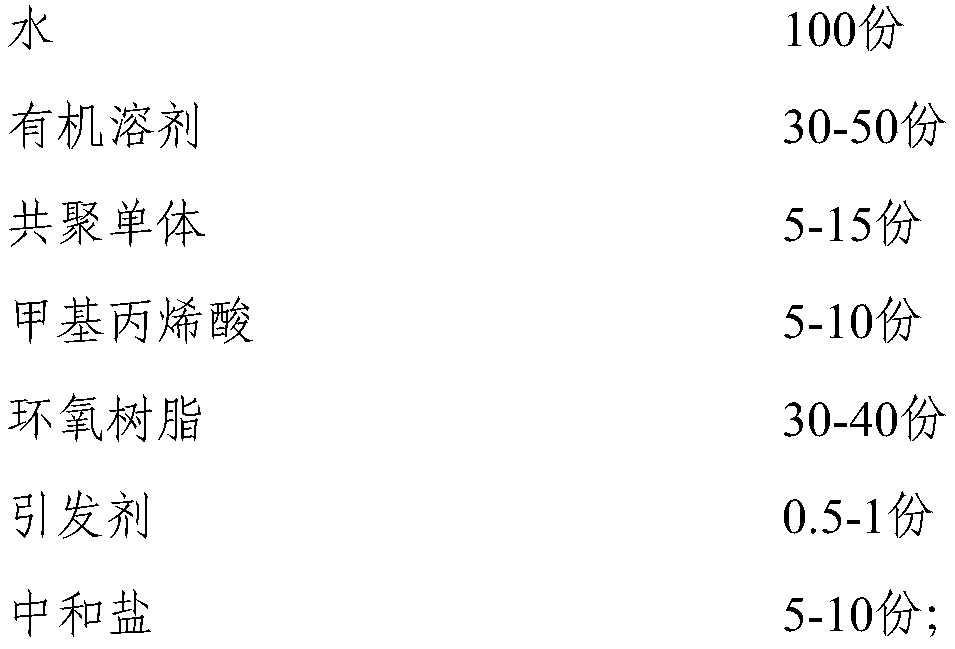

[0085] The present embodiment provides a kind of aqueous epoxy resin crosslinking agent, and it is made by the raw material of following weight ratio:

[0086]

[0087] Present embodiment also provides the preparation method of this aqueous epoxy resin crosslinking agent, as follows:

[0088] Add 35kg of epoxy resin (E44), 20kg of ethylene glycol monobutyl ether, and 20kg of n-butanol into a four-neck flask, heat and stir at a speed of 700 rpm to raise the temperature to about 110°C;

[0089] Add a mixed solution of 8 kg of methacrylic acid, 6 kg of methyl methacrylate, 6 kg of styrene and 0.8 kg of benzoyl peroxide dropwise with a constant pressure dropping funnel within 2 hours, while raising the temperature to about 120 ° C, and keep the temperature for 2 hours;

[0090] After the reaction was completed, the temperature was lowered to 85°C, a mixed solution of 8kg triethylamine and 100kg water was added and stirred at a high speed of 6000 rpm, and kept at 50°C for 1 hour...

Embodiment 2

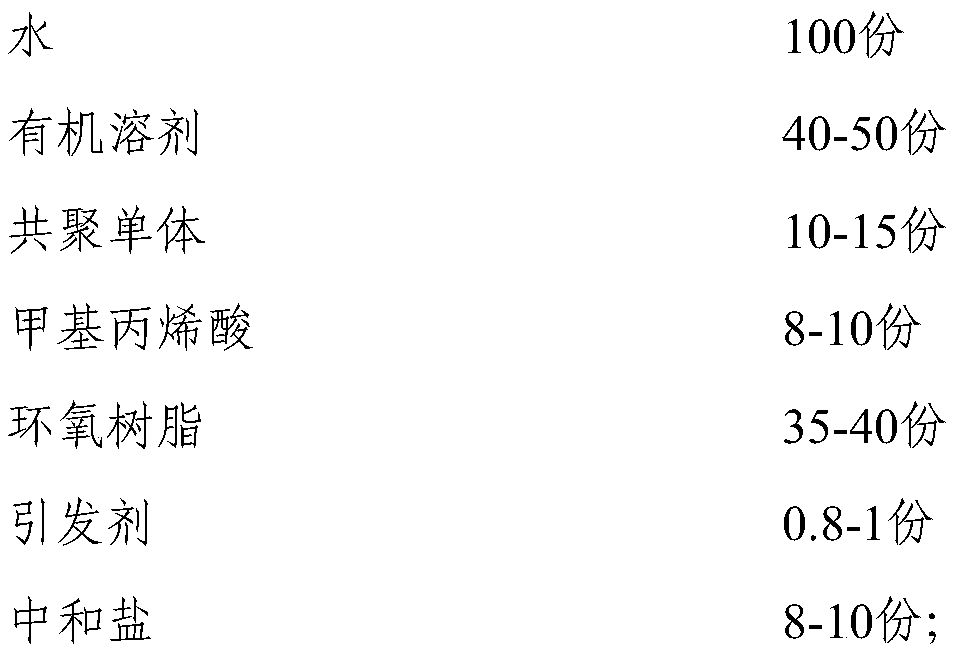

[0100] The present embodiment provides a kind of aqueous epoxy resin crosslinking agent, and it is made by the raw material of following weight ratio:

[0101]

[0102] The present embodiment also provides the preparation method of this aqueous epoxy resin crosslinking agent, specifically as follows:

[0103] Add 36kg of epoxy resin (E44), 10kg of ethylene glycol monobutyl ether, and 30kg of n-butanol into a four-neck flask, heat and stir at a speed of 1000 rpm to raise the temperature to about 110°C.

[0104] Add a mixed solution of 10kg of methacrylic acid, 7kg of methyl methacrylate, 8kg of styrene and 0.9kg of benzoyl peroxide dropwise with a constant pressure dropping funnel within 2 hours, while raising the temperature to about 120°C, and keep the temperature for 2 hours.

[0105] After the reaction was completed, the temperature was lowered to 85°C, a mixed solution of 9kg of triethanolamine and 100kg of water was added and stirred at a high speed at a speed of 7000 ...

Embodiment 3

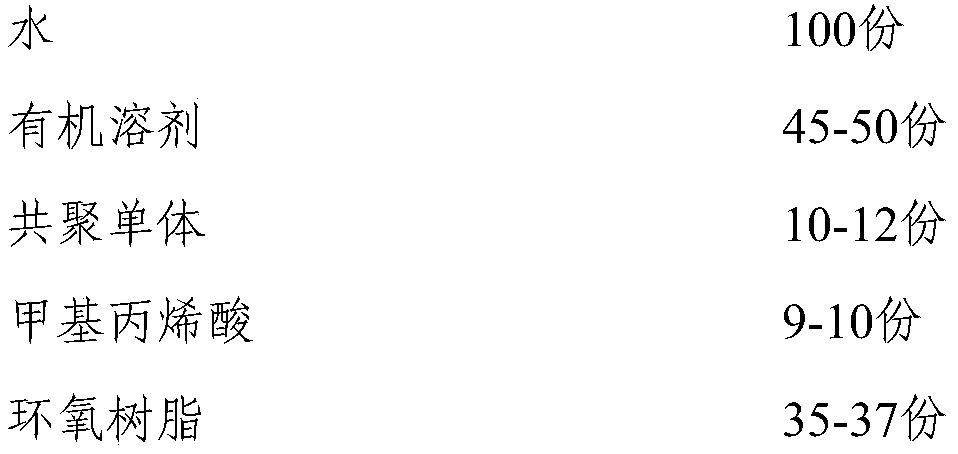

[0116] The present embodiment provides a kind of aqueous epoxy resin crosslinking agent, and it is made by the raw material of following weight ratio:

[0117]

[0118] Present embodiment also provides the preparation method of this aqueous epoxy resin crosslinking agent, as follows:

[0119] Add 40kg of epoxy resin (E44) and 40kg of n-butanol into a four-necked flask, heat and stir at a speed of 1200 rpm to raise the temperature to about 110°C.

[0120] Add a mixed solution of 9 kg of methacrylic acid, 7 kg of methyl methacrylate, 7 kg of styrene and 1 kg of benzoyl peroxide dropwise with a constant pressure dropping funnel within 2 hours, while raising the temperature to about 120°C, and keep the temperature for 2 hours.

[0121] After the reaction was completed, the temperature was lowered to 85°C, and a mixed solution of 10kg dimethylethanolamine and 100kg water was added and stirred at a high speed at a speed of 6000 rpm, and kept at 50°C for 1 hour to prepare a water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com