A kind of multi-element copper alloy and its preparation method and application in additive manufacturing

A copper alloy, multi-component technology, applied in the field of multi-component copper alloy and its preparation, can solve the problems of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

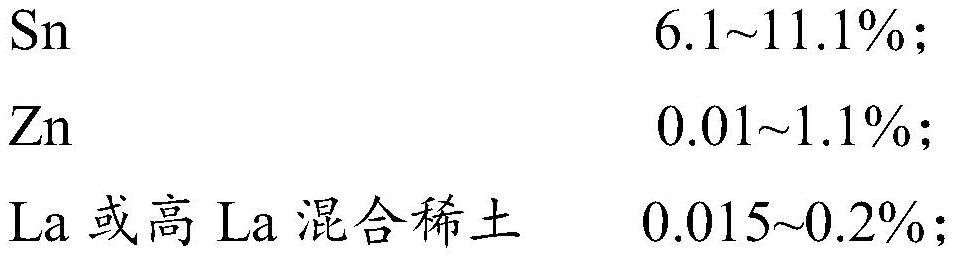

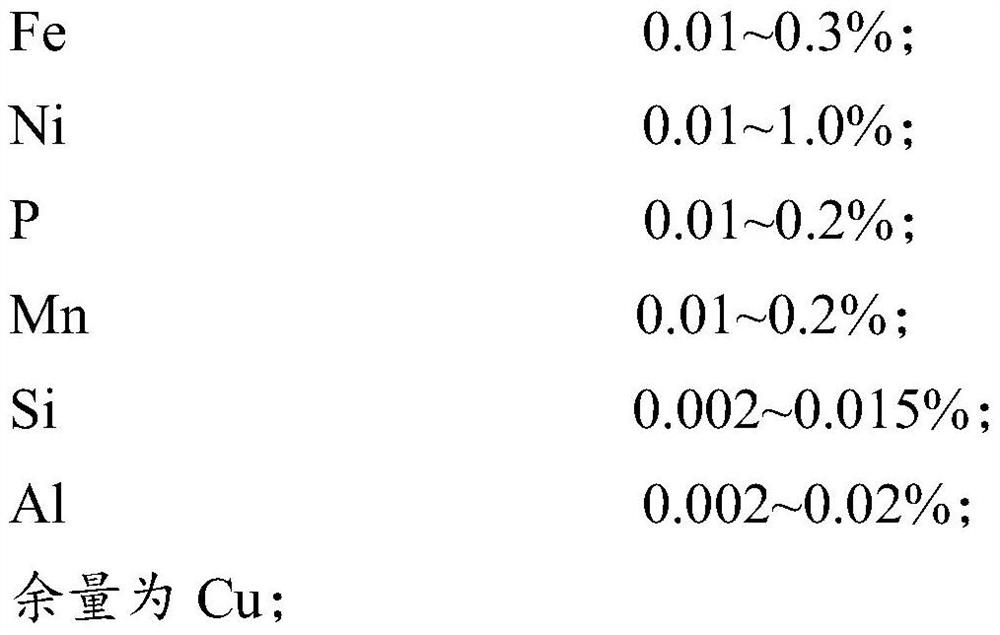

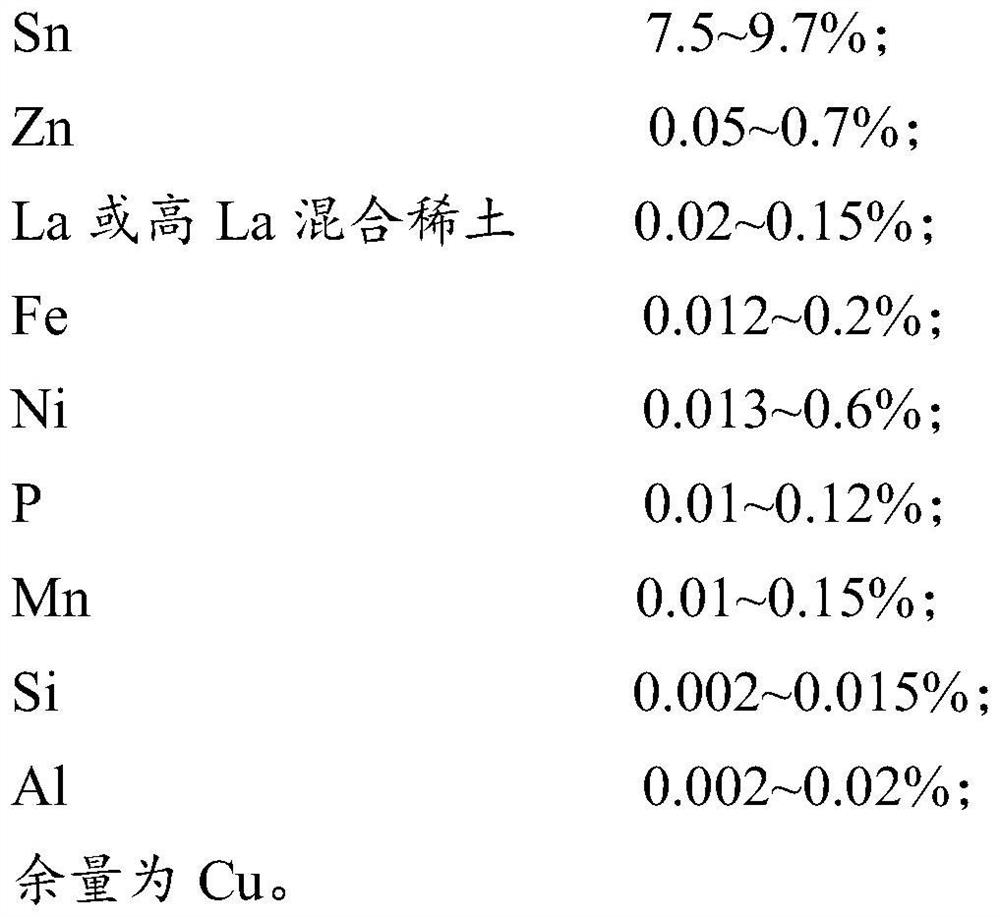

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides the preparation method of above-mentioned multi-element copper alloy, comprises the following steps:

[0042] (1) Melting electrolytic copper, then adding Ni, CuFe master alloy and CuMn master alloy to carry out the first mixed smelting to obtain a pre-mixed melt;

[0043](2) sequentially adding Zn, Sn, phosphorus copper deoxidizer, refining agent, La or high La mixed rare earth to the premixed melt for the second mixed smelting to obtain a mixed melt;

[0044] (3) The mixed melt is subjected to heat preservation and standing, heating treatment, slag removal and casting out of the furnace in sequence to obtain a multi-element copper alloy.

[0045] The invention melts the electrolytic copper, then adds Ni, CuFe master alloy and CuMn master alloy to carry out the first mixing and smelting to obtain the premixed melt. In the present invention, it is preferable to add electrolytic copper and cover charcoal in the furnace to isolate oxygen; i...

Embodiment 1

[0059] According to the mass percentage of each component of the alloy in Table 1, the multi-element copper alloy is prepared, and the specific preparation method is as follows:

[0060] (1) Add electrolytic copper into the melting furnace and cover it with charcoal, fully melt the copper, add nickel, CuFe master alloy, and CuMn master alloy, and carry out mixed melting at 1250°C for 5 minutes;

[0061] (2) Add zinc and tin at a furnace temperature of 1160°C and stir evenly, add CuP14 phosphorus copper deoxidizer and stir evenly, then add refining agent and lanthanum to mix and melt for 3 minutes;

[0062] (3) After stirring, carry out component analysis and adjustment, wherein the analysis and adjustment components include the following steps:

[0063] (a) Analyze the chemical composition with a direct-reading spectrometer, and adjust the composition ratio;

[0064] (b) use a metallographic microscope to detect the metallographic structure and physical performance test;

[...

Embodiment 2

[0069] According to the mass percentage of each alloy component in Table 1, a multi-element copper alloy was prepared, and the specific preparation method was as in Example 1. The metallographic structure diagram and figure 1 resemblance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com