Tissue engineering bone based on multi-layer cell grid and preparation method for tissue engineering bone

A technology for tissue engineering bone and stratified cells, applied in tissue regeneration, pharmaceutical formulations, additive processing, etc., can solve the problems of non-degradation, poor mechanical properties, etc., and achieve the effect of maintaining activity, high strength, and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

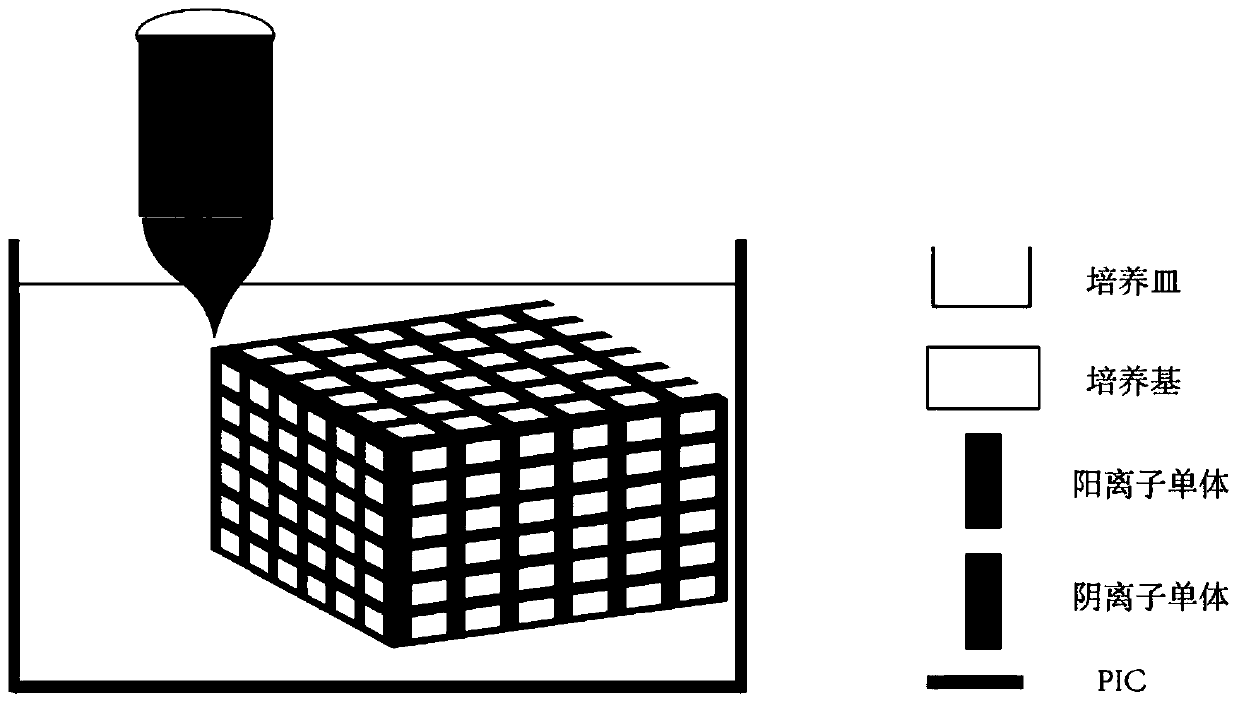

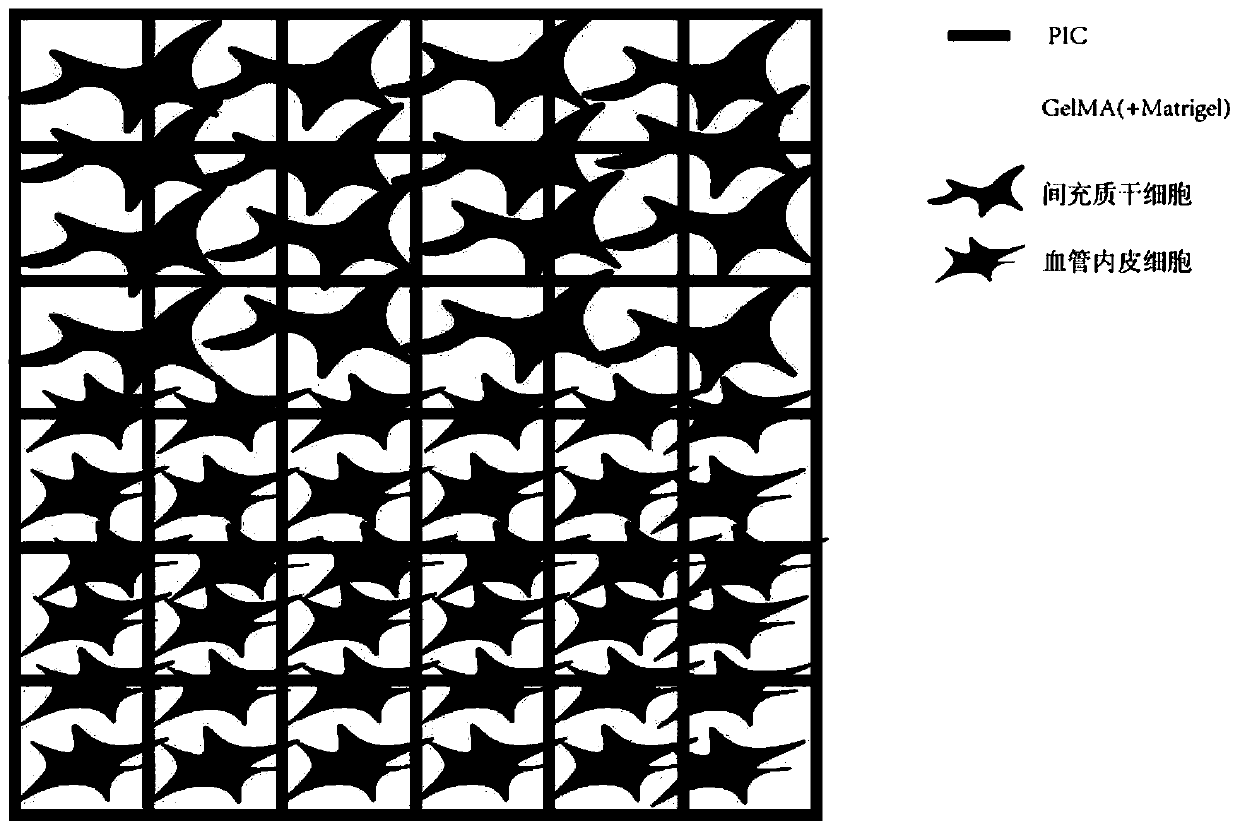

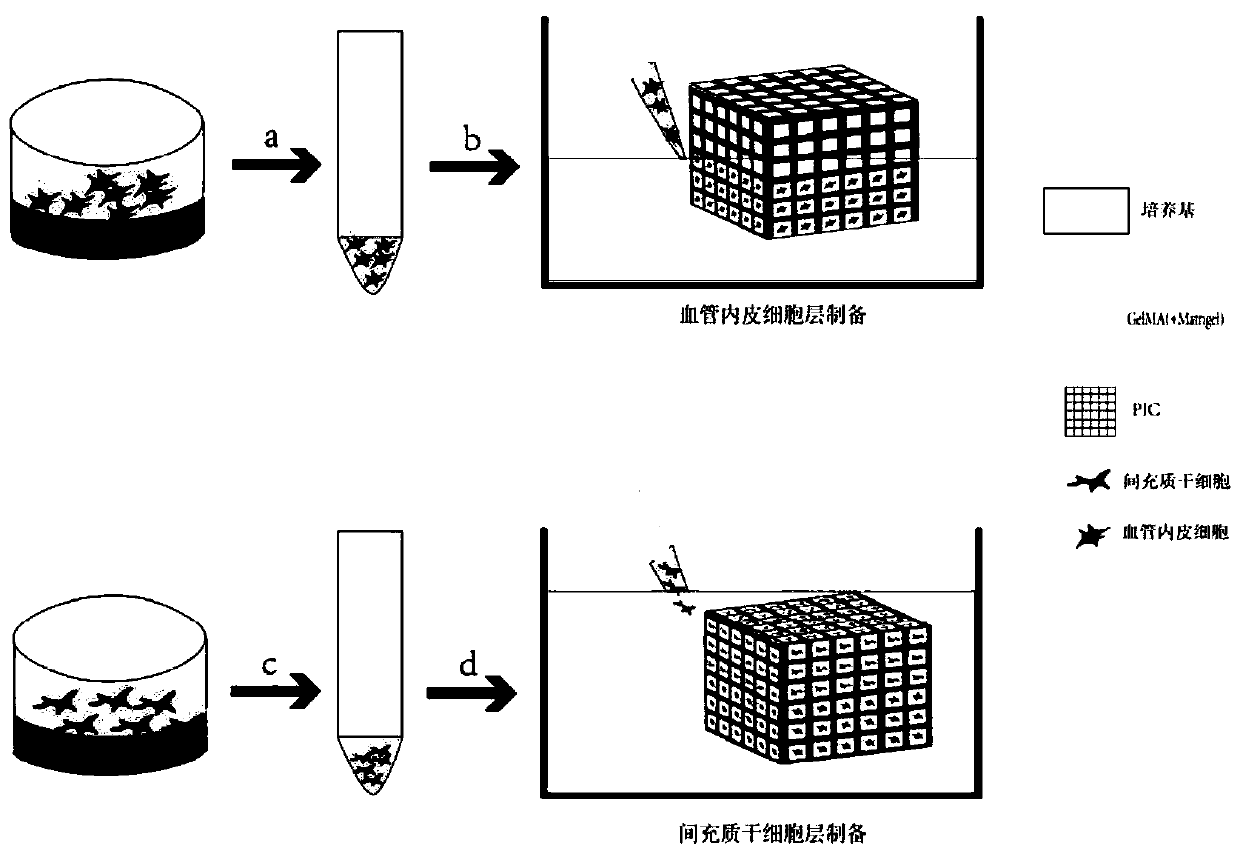

[0041] 1. Preparation of the grid support

[0042] (1) Preparation of printing materials

[0043] Add sodium p-styrene sulfonate (NaSS, anionic monomer) and 3-(methacryloylamino) propyl trimethyl ammonium chloride (MPTC, cationic monomer) into 0.05 mol% 2-ketoglutamate, respectively Acid (photoinitiator) was irradiated with ultraviolet light of 7.5mW / cm2 at 365nm wavelength for 8 hours to prepare 1mol / L anion precursor aqueous solution and cationic precursor aqueous solution respectively. Then it was added to ethanol to precipitate, and the precipitate was dried in an oven. Obtained are PMPTC transparent particles with a weight average molecular weight of 4x103 g / mol and a polydispersity of 1.5 and PNaSS transparent particles with a weight average molecular weight of 1x106 g / mol and a polydispersity of 3.4. Dissolve the two transparent polymer particles in deionized water to prepare a 0.095-0.125mol / L solution, slowly drip equal volumes of the two solutions into 250mL deionized w...

Embodiment 2

[0057] 1. Preparation of the grid support

[0058] (1) Preparation of printing materials

[0059] Add sodium p-styrene sulfonate (NaSS, anionic monomer) and 3-(methacryloylamino) propyl trimethyl ammonium chloride (MPTC, cationic monomer) into 0.05 mol% 2-ketoglutamate, respectively Acid (photoinitiator) was irradiated with ultraviolet light of 7.5mW / cm2 at 365nm wavelength for 8 hours to prepare 1mol / L anion precursor aqueous solution and cationic precursor aqueous solution respectively. Then it was added to ethanol to precipitate, and the precipitate was dried in an oven. Obtained are PMPTC transparent particles with a weight average molecular weight of 4x103 g / mol and a polydispersity of 1.5 and PNaSS transparent particles with a weight average molecular weight of 1x106 g / mol and a polydispersity of 3.4. Dissolve the two transparent polymer particles in deionized water to prepare a 0.095-0.125mol / L solution, slowly drip equal volumes of the two solutions into 250mL deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com