Nano noble metal modified Ag/MXene/TiO2 composite material and preparation method thereof

A technology of composite materials and precious metals, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as photocatalytic properties that are rarely studied, and achieve easy control, low cost, and improved photoresponse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 1 g Ti 3 AlC 2 The powder was dispersed in 10 mL of 49% HF solution, then placed in polytetrafluoroethylene, and reacted at 60 °C for 24 h. The resulting powder was washed with deionized water to a pH of about 7, and washed three times with ethanol centrifugation, and finally the product was vacuum-dried at 60 °C for 24 h to obtain MXene powder. Weigh 0.25 mmol AgNO 3 and 3.28 mmol MXene were dissolved in 50 mL deionized water, mixed, and ultrasonicated for 30 min to obtain A solution. Weigh 0.25 mmol of SnCl 2 and 0.5 mmol of CF 3 COOH solution was dissolved in 3 mL of formaldehyde and 7 mL of deionized water, and ultrasonicated for 30 min to obtain solution B. The prepared solution B was slowly dropped into the solution A to mix well, ultrasonicated for 30 min, washed by centrifugation, and dried in vacuum to prepare nano-Ag modified Ag / MXene composites. Weigh 100 mgAg / MXene complex and 0.165 g NaBF 4 Dissolved in 15mL of 1M HCl, hydrothermally reacted a...

Embodiment 2-4

[0032] Other steps remain unchanged, the mass percentages of Ag added are 1%, 5% and 10%, respectively, and Ag / MXene / TiO 2 composite photocatalyst. The specific formula is shown in Table 2. In addition, the reaction temperature and time were changed between 120-220 ℃ and 1-36 h, respectively.

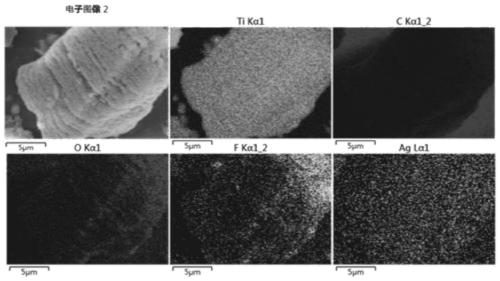

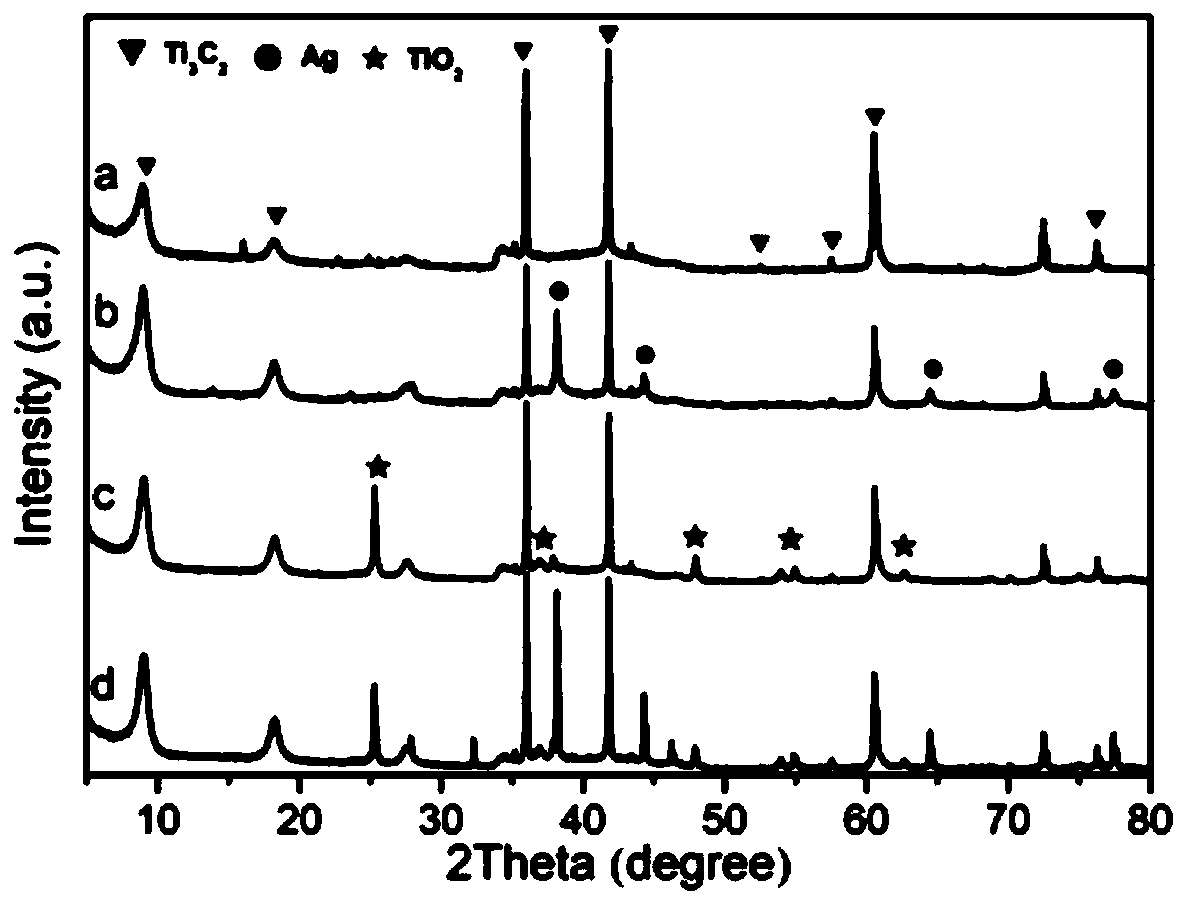

[0033] MXene, Ag / MXene composite and Ag / MXene / TiO obtained in above-mentioned embodiments 1 ~ 4 2 The composites were analyzed by field emission scanning electron microscopy (FESEM), X-ray diffraction (XRD), and ultraviolet-visible spectroscopy (UV-vis).

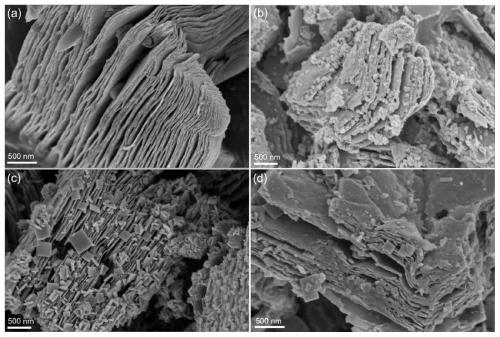

[0034] figure 1 For MXene, 5%Ag / MXene, MXene / TiO 2 and 5%Ag / MXene / TiO 2 SEM images of samples. From figure 1 a It can be seen that MXene has a clear lamellar shape and a good layering effect. figure 1 b It can be observed that more uniform Ag nanoparticles are deposited on the surface of MXene, and Ag nanoparticles grow between layers of MXene. After hydrothermal reaction, in MXene ( figure 1 c) and 5%Ag / MXene ( figure 1 d)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com