Comprehensive utilization method of high-aluminum-content waste alkali liquor

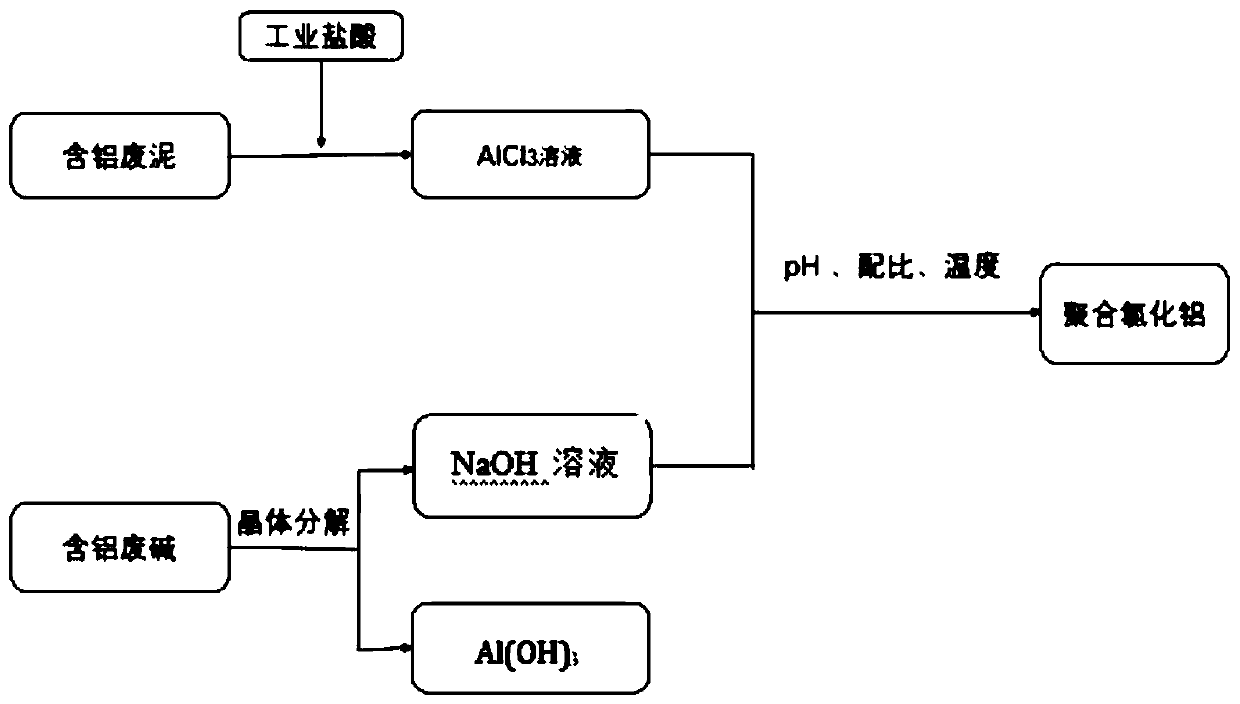

A technology of aluminum waste and lye, applied in the preparation of aluminum chloride, aluminum halide, alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of consumption of neutralizing agents, waste of aluminum resources and alkali resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 160ml of high-aluminum-containing waste lye (the mass fraction of aluminum is 20.16% based on Al2O3, the content of free sodium hydroxide is 21.97%, and the caustic ratio is 1.39), 160ml of tap water, 7g of aluminum hydroxide crystals, and a seed crystal coefficient of 0.1. Place in a corrosion-resistant reaction kettle, stir and react at room temperature for 72 hours, and then separate the solid and liquid by suction filtration. Collect the filtrate. The obtained aluminum hydroxide was washed with water to neutrality, and baked at 130 degrees Celsius for 2 hours to obtain 54 g of aluminum hydroxide powder, and the recovery rate of aluminum hydroxide was 67.14%.

Embodiment 2

[0024] 200ml of high aluminum-containing waste lye (the aluminum is 19.86% based on the mass fraction of aluminum oxide, the content of free sodium hydroxide is 23.49%, and the caustic ratio is 1.51), 200ml of tap water, 11.4 aluminum hydroxide crystals, and a seed crystal coefficient of 0.13. Place in a corrosion-resistant reaction kettle, stir and react at room temperature for 72 hours, and then separate the solid and liquid by suction filtration. Collect the filtrate. The obtained aluminum hydroxide was washed with water to neutrality, and baked at 130 degrees Celsius for 2 hours to obtain 67 g of aluminum hydroxide, and the recovery rate of aluminum hydroxide was 63.40%.

Embodiment 3

[0026] 320ml of high-aluminum-containing waste lye (the aluminum is 19.86% based on the mass fraction of aluminum oxide, the content of free sodium hydroxide is 23.49%, and the caustic ratio is 1.51), 160ml of tap water, 41.5g of aluminum hydroxide crystals, and a seed crystal coefficient of 0.3. Place in a corrosion-resistant reaction kettle, stir and react at room temperature for 72 hours, and then separate the solid and liquid by suction filtration. Collect the filtrate. The obtained aluminum hydroxide was washed with water until neutral, and baked at 130 degrees Celsius for 2 hours to obtain 119.4 g of aluminum hydroxide, and the recovery rate of aluminum hydroxide was 56.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com