Polyimide film and preparation method thereof

A polyimide film and polyimide technology, applied in the field of polyimide film, can solve the problem of the reduction of insulation and mechanical properties of polyimide film, potential safety hazards in the use of electronic devices, and thermal conductivity of polyimide film To improve the dispersion, increase thermal conductivity and mechanical properties, improve heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

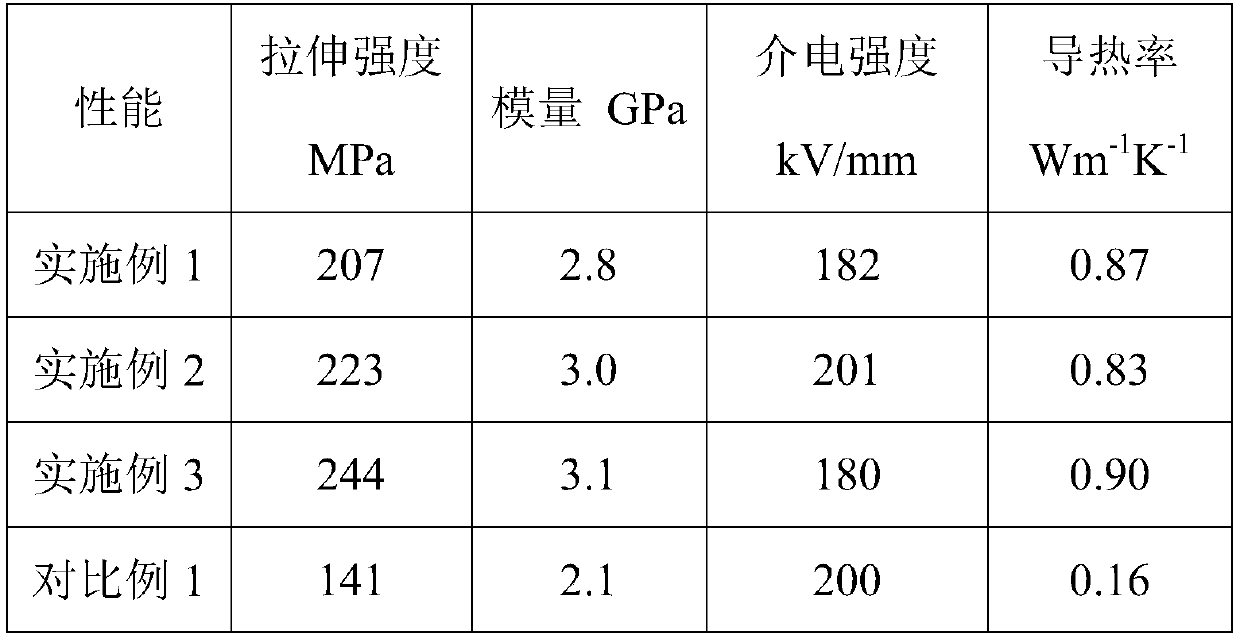

Examples

Embodiment 1

[0027] A kind of polyimide film, its raw material comprises: polyimide and modified carbon fiber, wherein, the content of modified carbon fiber is 20wt%;

[0028] In the preparation process of the modified carbon fiber, the carbon fiber was taken in concentrated nitric acid, ultrasonically pickled at 70°C for 4 hours, then washed with water, and dried to obtain the intermediate fiber; the intermediate fiber was evenly dispersed in the ethanol aqueous solution with a volume fraction of 90%, and the Adjust the pH to 9.5 with ammonia water, then add tetraethyl orthosilicate, stir and react at 70°C for 8 hours, then centrifuge, take the precipitate, wash it, and dry it to obtain the silica-coated carbon fiber; ultrasonically disperse the silica-coated carbon fiber at a mass fraction In a 7wt% 3-aminopropyltriethoxysilane solution, ultrasonically stir at 70°C for 2h, filter, wash the filter cake, and dry to obtain modified carbon fibers, wherein the 3-aminopropyltriethoxysilane solu...

Embodiment 2

[0031] A kind of polyimide film, its raw material comprises: polyimide and modified carbon fiber, wherein, the content of modified carbon fiber is 30wt%;

[0032] In the preparation process of the modified carbon fiber, the carbon fiber was taken in concentrated nitric acid, ultrasonically pickled at 60°C for 5 hours, then washed with water, and dried to obtain the intermediate fiber; the intermediate fiber was evenly dispersed in the ethanol aqueous solution with a volume fraction of 80%. Adjust the pH to 10 with ammonia water, then add tetraethyl orthosilicate, stir and react at 60°C for 10 hours, then centrifuge, take the precipitate, wash it, and dry it to obtain the silica-coated carbon fiber; ultrasonically disperse the silica-coated carbon fiber at a mass fraction 5wt% 3-aminopropyltriethoxysilane solution, ultrasonically stirred at 60°C for 3h, filtered, washed the filter cake, and dried to obtain modified carbon fibers, wherein the 3-aminopropyltriethoxysilane solution...

Embodiment 3

[0035] A kind of polyimide film, its raw material comprises: polyimide and modified carbon fiber, wherein, the content of modified carbon fiber is 25wt%;

[0036] During the preparation of the modified carbon fiber, the carbon fiber was ultrasonically pickled in concentrated nitric acid for 4.5 hours at 65°C, then washed with water, and dried to obtain the intermediate fiber; the intermediate fiber was uniformly dispersed in an ethanol aqueous solution with a volume fraction of 85%, Use ammonia water to adjust the pH to 9.7, then add tetraethyl orthosilicate, stir and react at 65°C for 9 hours, then centrifuge, take the precipitate, wash it, and dry it to obtain silica-coated carbon fibers; ultrasonically disperse the silica-coated carbon fibers in mass In a 3-aminopropyltriethoxysilane solution with a fraction of 6wt%, ultrasonically stir at 65°C for 2.5h, filter, wash the filter cake, and dry to obtain modified carbon fibers, wherein 3-aminopropyltriethoxy The solvent of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com