A kind of aluminum nitride epitaxial structure and growth method thereof

An epitaxial structure and growth method technology, applied in the field of semiconductor light-emitting diodes, can solve problems such as difficulty in obtaining a smooth and flat AlN epitaxial layer, unfavorable lateral growth and merging of AlN epitaxial layers, etc., so as to improve internal quantum efficiency, promote lateral growth merging, and accelerate transformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

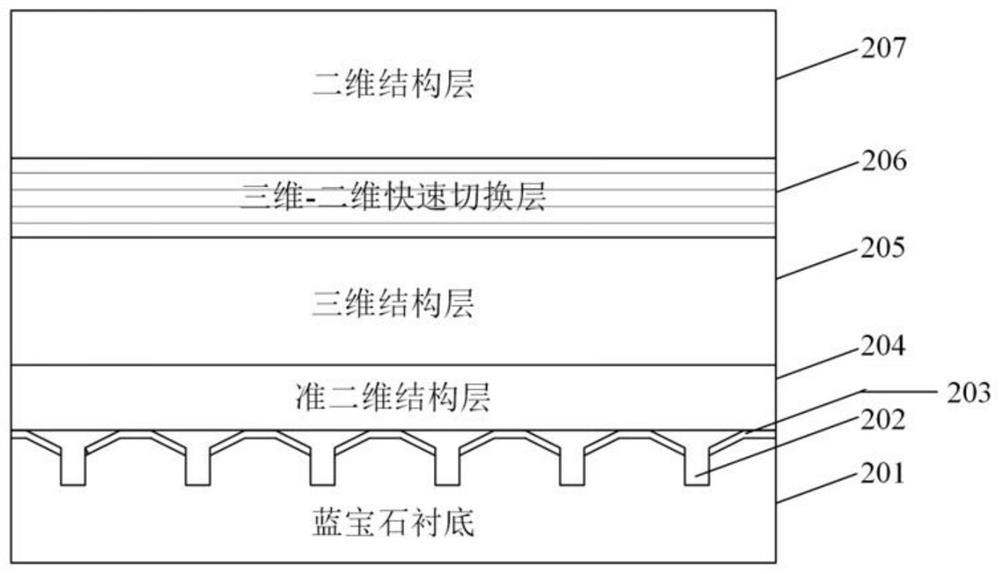

[0032] An embodiment of the present invention provides an aluminum nitride epitaxial structure, figure 1 A schematic structural diagram of an aluminum nitride epitaxial structure provided in this embodiment. see figure 1 , the aluminum nitride epitaxial structure sequentially includes a sapphire substrate 201, a nano-pattern array 202, an AlN nucleation layer 203, a quasi-two-dimensional structure layer 204, a three-dimensional structure layer 205, a three-dimensional-two-dimensional fast switching layer 206 and Two-dimensional structure layer 207 .

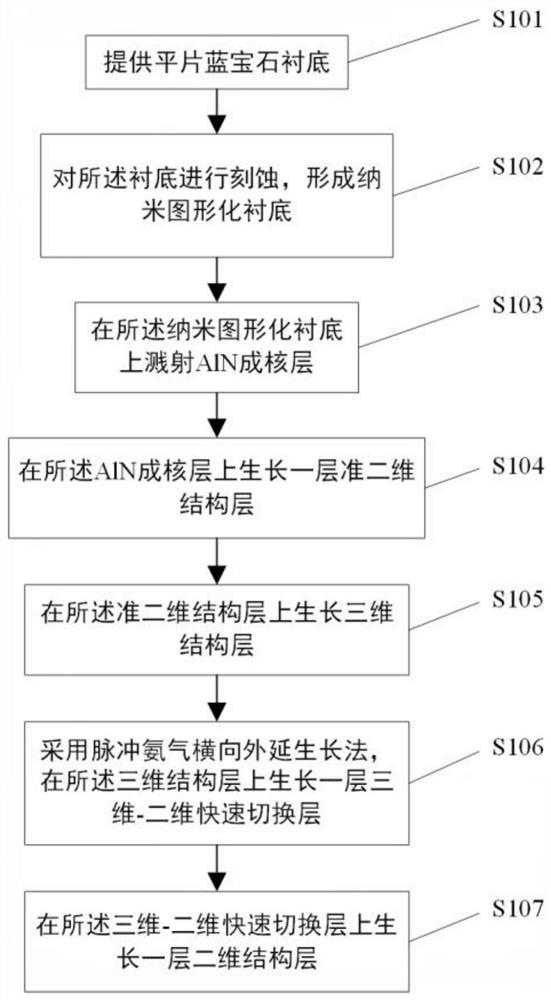

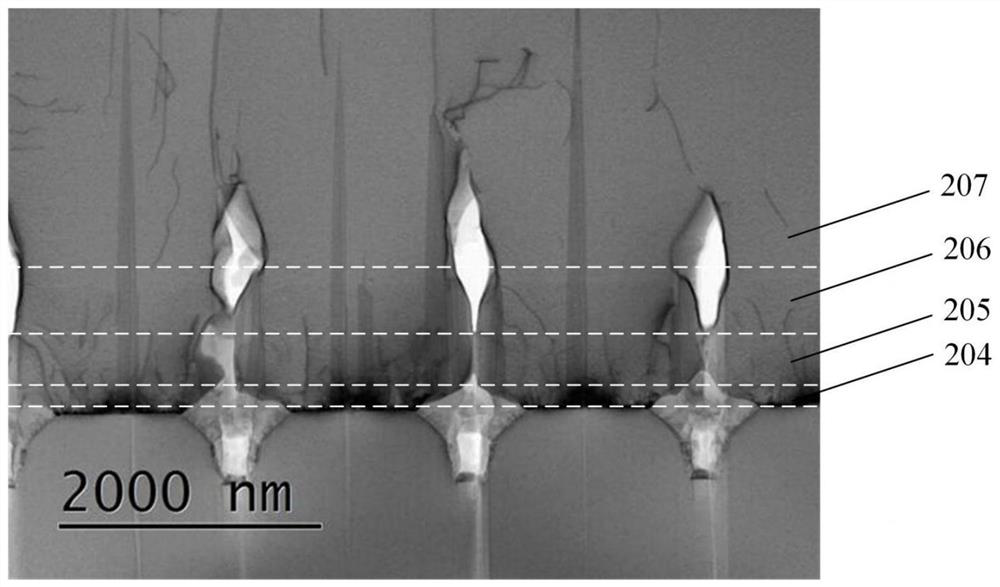

[0033] An embodiment of the present invention provides a method for growing an aluminum nitride epitaxial structure, figure 2 A flowchart of a method for growing an aluminum nitride epitaxial structure provided in this embodiment, image 3 A cross-sectional TEM image of an aluminum nitride epitaxial structure provided for an embodiment of the present invention, see figure 1 and image 3 , the production method includes: suc...

Embodiment 2

[0049] An embodiment of the present invention provides an aluminum nitride epitaxial structure, which sequentially includes a silicon carbide substrate 201, a nano-pattern array 202, an AlN nucleation layer 203, a quasi-two-dimensional structure layer 204, A three-dimensional structure layer 205 , a three-dimensional-two-dimensional fast switching layer 206 and a two-dimensional structure layer 207 .

[0050] An embodiment of the present invention provides a method for growing an aluminum nitride epitaxial structure, which specifically includes the following steps:

[0051] S101: providing a flat silicon carbide substrate 201;

[0052] S102: Etching the nano-pattern array 202 on the silicon carbide substrate 201;

[0053] Specifically, the nanopatterned array 202 is a pit-deep pit nanopattern array, and the specific structure is as follows Figure 4 As shown, the pit type is a rounded table pit 202-1 and a cylindrical deep pit 202-2, and the cylindrical deep pit 202-2 is etc...

Embodiment 3

[0066] An embodiment of the present invention provides an aluminum nitride epitaxial structure, which sequentially includes a silicon substrate 201, a nano-pattern array 202, an AlN nucleation layer 203, a quasi-two-dimensional structure layer 204, a three-dimensional Structure layer 205 , 3D-2D fast switching layer 206 and 2D structure layer 207 .

[0067] An embodiment of the present invention provides a method for growing an aluminum nitride epitaxial structure, which specifically includes the following steps:

[0068] S101: providing a flat silicon substrate 201;

[0069] S102: Etching the nano-pattern array 202 on the silicon substrate 201;

[0070] Specifically, the nanopatterned array 202 is a pit-deep pit nanopattern array, and the specific structure is as follows Figure 4 As shown, the pit type is a rounded table pit 202-1 and a cylindrical deep pit 202-2, and the cylindrical deep pit 202-2 is etched at the bottom of the rounded bench pit 202-1. The pattern period...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com