A kind of coating material, live black soldier fly larva coating bait and its preparation method and application

A technology for black soldier flies and larvae, which is applied in the application, fishing accessories, fishing and other directions, can solve the problems of restricting the development of the forest frog aquaculture industry, affecting the growth and development of the forest frog, and nutritional ratio imbalance, etc. The effect of shortening oil production cycle and weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides the preparation method of the black soldier fly larvae living body coating bait described in the above scheme, comprising the following steps:

[0032] 1) mixing and boiling part of the coating material and water at 95 to 100°C for 5 to 8 minutes to obtain a coating solution with a concentration of 38 to 40 Baume degrees;

[0033] 2) after the living body of the black soldier fly larvae is washed with clear water, it is placed on a gauze cloth and laid out to dry, and the body surface of the worm is dried to obtain the living body of the black soldier fly larvae to be treated;

[0034] 3) After cooling the coating liquid to 15-25° C., immerse the living body of the black soldier fly larvae to be treated in the cooled coating liquid, take out the living body of the black soldier fly larvae wrapped with the coating liquid, and let stand to obtain the coating larva;

[0035] 4) spread the remaining coating material on the coated larvae ...

Embodiment 1

[0049] Example 1 Comparison of water resistance of the larvae bait of Rana wood

[0050] 1. Materials: 100 3-4 instar Tenebrio molitors, 100 3-4 instar black soldier flies larvae, 100 3-4 instar fly maggots, 100 1-year-old earthworms, 10L normal temperature mineral water, timer, 2.5L beaker 4 pieces, 4 pieces of 40 mesh fences, and many pieces of white cardboard (30×30cm).

[0051] Source of material: Jilin Provincial Sericulture Research Institute.

[0052] 2. Method: Pour 2L of mineral water into 4 beakers respectively, and simultaneously pour four kinds of experimental insects into different beakers at the same time, and start timing. When it was observed that 10 (10%) of the experimental insects died in the water, the time was recorded, fished out with a fence, and placed on a white cardboard for confirmation.

[0053] 3. The results are shown in Table 1:

[0054] Table 1 Comparison results of water resistance of the larvae bait of Rana wood

[0055] type Qu...

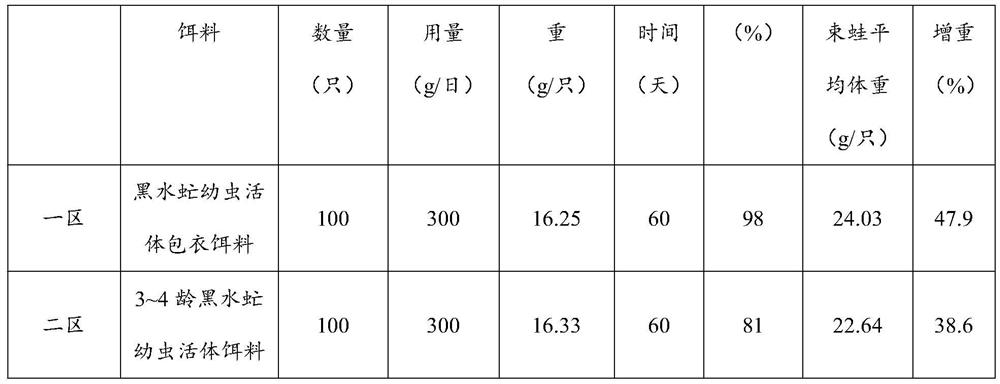

Embodiment 2

[0058] Embodiment 2 A kind of black soldier fly larvae living body coating bait

[0059] 1. Components of coating material: defatted soybean powder 300g, tussah moth powder (seed waste) 350g, soybean oil 30g, corn starch 200g, multi-dimensional element tablet (Anhui Jinhui Pharmaceutical Co., Ltd.) 1g, calcium, phosphorus and magnesium supplements Zinc iron (veterinary use, Daqing Boshen Biotechnology Co., Ltd.) 10g, xanthan gum (food thickener, Shenzhen Xingmu Biological Engineering Co., Ltd.) 20g.

[0060] 2. Feed: live 3-4 instar black soldier fly larvae.

[0061] 3. Coating method: fully mix the coating materials and divide them into 3 equal parts, of which 2 parts are boiled with water at 100°C, and the concentration of the boiled coating liquid is controlled at 38 to 40 Baume degrees (using wave When it is cooled to 15-20°C, the live 3-4 instar black soldier fly larvae after cleaning and drying are immersed in the coating solution, fully mixed, and then taken out with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com