Preparation method of composite material solar photovoltaic module frame

A solar photovoltaic and component frame technology, applied in photovoltaic modules, photovoltaic power generation, electrical components, etc., can solve the problems of easy pollution, poor wear resistance, poor heat dissipation, etc., and achieve good protection, high support strength, and good weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

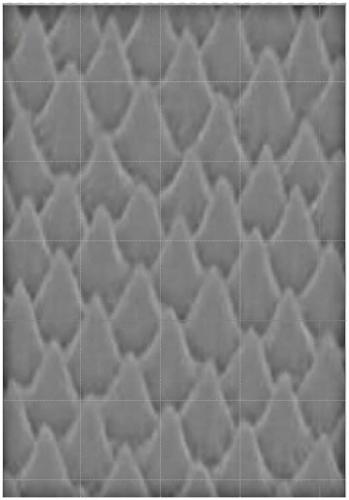

Image

Examples

Embodiment 1

[0029] In an embodiment of the present invention, a method for preparing a frame of a composite solar photovoltaic module includes the following steps:

[0030] S1, mix the resin with a mass fraction of 150 parts, 30 parts of additives and 35 parts of inorganic fillers, and stir evenly;

[0031] S2, adding short fibers with a mass fraction of 30 parts to the resin mixture obtained in S1, and dispersing by ultrasonic vibration and stirring to form a mixed glue;

[0032] S3, the glass fiber untwisted continuous roving with a mass fraction of 300 parts is dipped in a dispersant and dried;

[0033] S4, placing the mixed glue solution obtained in S2 in a dipping tank, and then evenly arranging and impregnating the glass fiber untwisted continuous roving obtained in S3 in the dipping tank of the mould;

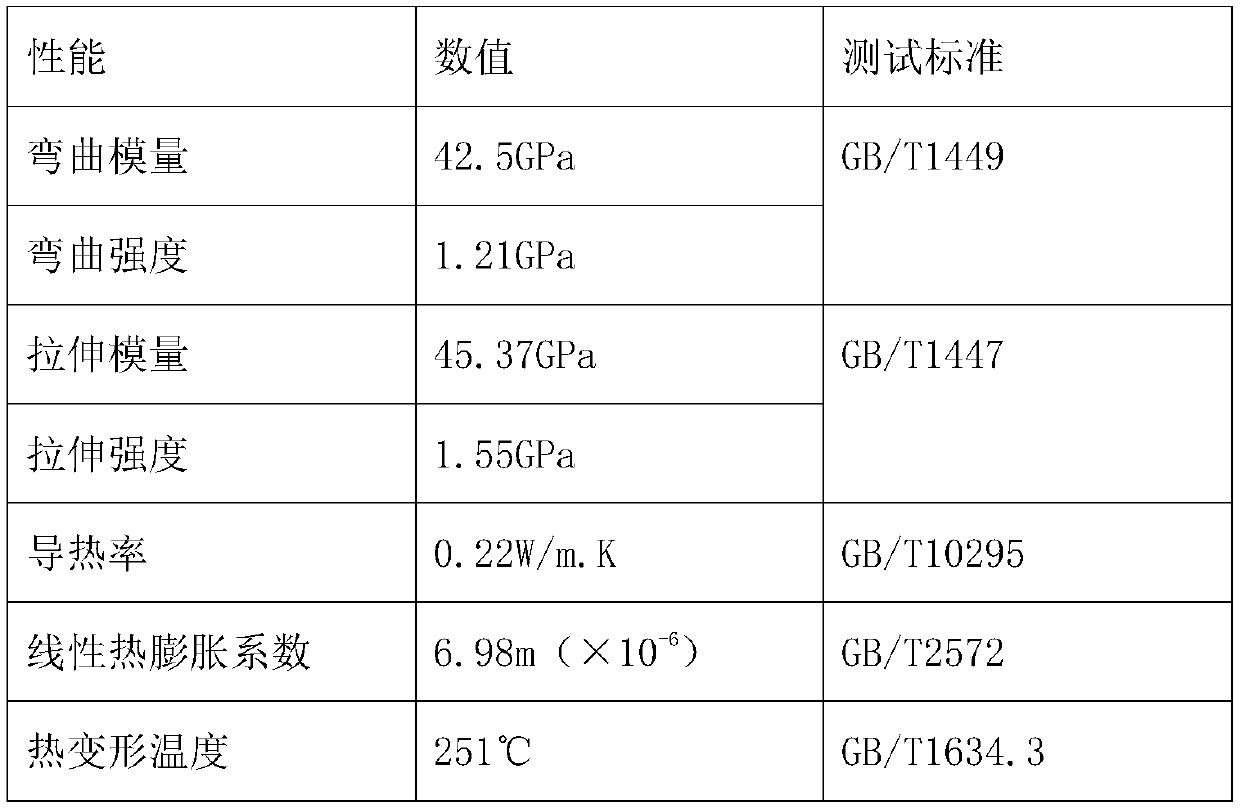

[0034] S5. Using a pultrusion molding machine, at a mold temperature of 170° C. and a pulling speed of 1 m / min, the glass fiber untwisted continuous roving impregnated with the res...

Embodiment 2

[0042] A method for preparing a frame of a composite solar photovoltaic module, comprising the following steps:

[0043]S1. Mix the resin with a mass fraction of 100 parts, 5 parts of additives and 5 parts of inorganic filler, and stir evenly;

[0044] S2, adding short fibers with a mass fraction of 25 parts to the resin mixture obtained in S1, and dispersing by ultrasonic vibration and stirring to form a mixed glue;

[0045] S3, the glass fiber untwisted continuous roving with a mass fraction of 250 parts is dipped in a dispersant and dried;

[0046] S4, placing the mixed glue solution obtained in S2 in a dipping tank, and then evenly arranging and impregnating the glass fiber untwisted continuous roving obtained in S3 in the dipping tank of the mould;

[0047] S5. Using a pultrusion molding machine, at a mold temperature of 150° C. and a pulling speed of 1 m / min, the glass fiber untwisted continuous roving impregnated with the resin mixture is molded;

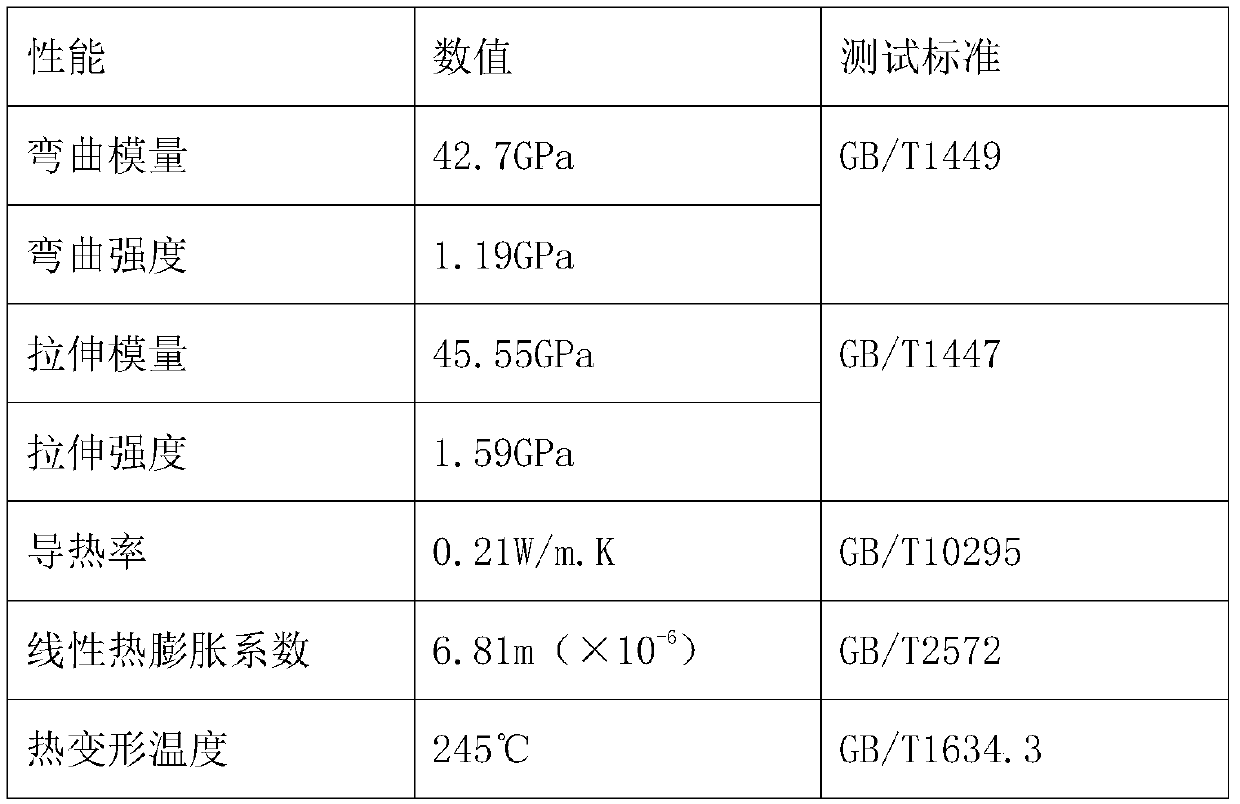

[0048] S6. Mix and ...

Embodiment 3

[0055] A composite solar photovoltaic module frame, comprising the following steps:

[0056] S1. Mix resin with a mass fraction of 175 parts, 20 parts of additives and 30 parts of inorganic filler, and stir evenly;

[0057] S2, adding short fibers with a mass fraction of 38 parts to the resin mixture obtained in S1, and dispersing by ultrasonic vibration and stirring to form a mixed glue;

[0058] S3, the glass fiber untwisted continuous roving that the mass fraction is 325 parts is dipped in dispersant and dried;

[0059] S4, placing the mixed glue solution obtained in S2 in a dipping tank, and then evenly arranging and impregnating the glass fiber untwisted continuous roving obtained in S3 in the dipping tank of the mould;

[0060] S5. Using a pultrusion molding machine, at a mold temperature of 180°C and a pulling speed of 2 / min, the glass fiber untwisted continuous roving impregnated with the resin mixture is molded;

[0061] S6. Mix and stir the mass fraction of 125 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com