A kind of acrylic acid modified waterborne polyurethane self-healing pressure-sensitive adhesive and its preparation method and application

A water-based polyurethane and acrylic technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, ester copolymer adhesives, etc., can solve the problems of easy residual glue, poor high temperature resistance, poor water resistance, etc., and achieve adhesion Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Method for preparing acrylic modified aqueous polyurethane self-repair pressure sensitive glue, including the following steps:

[0076] (1) Under 120 ° C, -0.1 mPa, the polytetrahydrofuranol 2000, dihydroxymethropac is vacuum dehydration;

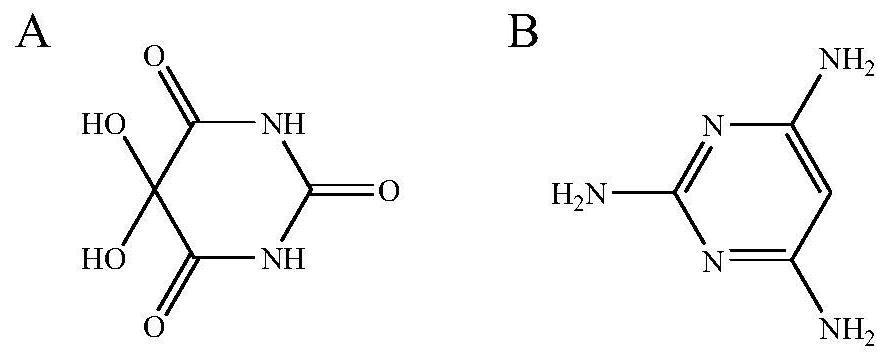

[0077] (2) Take the dried polytetrahydrofuran ether glycol 2000 (20 g, 10 mmol), dihydroxymethyl propionic acid (2.00 g, 14.91 mmol), hexamethylene diisocyanate (10.00 g, 59.46 mmol), Alooa A hydrate (2.00 g, 12.49 mmol), dibutyl tin (0.09 g, 0.14 mmol), anti-oxidant 1135 (0.10 g, 0.26 mmol) and acetone 30 mL were added to the four flasks, warmed to 86 ° C, stir Reaction 3.5 h; wherein the structural formula of the olyrene hydrate is figure 1 A figure shown in the map.

[0078] (3) Cooling to 55 ° C or less, 2,4,6-trisoprimidine (1.56 g, 12.48 mmol), trimethylolpropane (0.8 g, 5.96 mmol), temperature rise to step (2) reaction system. 70 ° C, stirring reaction 2 h; wherein the structural formula of 2,4,6-tripyrimidine is figure 1 The B fi...

Embodiment 2

[0084] Method for preparing acrylic modified aqueous polyurethane self-repair pressure sensitive glue, including the following steps:

[0085] (1) Under 120 ° C, -0.1 mPa, the polytetrahydrofuranol 2000, dihydroxymethropac is vacuum dehydration;

[0086] (2) Take the dried polytetrahydrofuran ether glycol 2000 (20 g, 10 mmol), dihydroxymethyl propionic acid (2.00 g, 14.91 mmol), hexamethylene diisocyanate (10.00 g, 59.46 mmol), Alooa A hydrate (2.00 g, 12.49 mmol), dibutyl tin (0.09 g, 0.14 mmol), anti-oxidant 1135 (0.10 g, 0.26 mmol) and acetone 30 mL were added to the four flasks, warmed to 86 ° C, stir Reaction 3.5 h; wherein the structural formula of the olyrene hydrate is figure 1 A figure shown in the map.

[0087] (3) Cooling to 55 ° C or less, 2,4,6-trisoprimidine (1.56 g, 12.48 mmol), trimethylolpropane (0.8 g, 5.96 mmol), temperature rise to step (2) reaction system. 70 ° C, stirring reaction 2 h; wherein the structural formula of 2,4,6-tripyrimidine is figure 1 The B fi...

Embodiment 3

[0093] Method for preparing acrylic modified aqueous polyurethane self-repair pressure sensitive glue, including the following steps:

[0094] (1) Under 120 ° C, -0.1 mPa, the polyethylene glycol 1000, dihydroxymethropac is vacuum dehydration;

[0095](2) Take the dried polyethylene glycol 1000 (10 g, 10 mmol), dihydroxymethyl proppropionic acid (2.00 g, 14.46 mmol), hexamethylene diisocyanate (10.00 g, 59.46 mmol), Al-Krea (2.00g, 12.49 mmol), Dikutanikhalate (0.09 g, 0.14 mmol), antioxidant 1135 (0.10 g, 0.26 mmol) and acetone 30 ml Add four flasks, warmed to 86 ° C, stirring reaction 3.5 H; wherein the structural formula of the olyrene hydrate is as figure 1 A figure shown in the map.

[0096] (3) Cooling to 55 ° C or less, 2,4,6-trisoprimidine (1.56 g, 12.48 mmol), trimethylolpropane (0.8 g, 5.96 mmol), temperature rise to step (2) reaction system. 70 ° C, stirring reaction 2 h; wherein the structural formula of 2,4,6-tripyrimidine is figure 1 The B figure in the B is shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com