Fuel cell electrode catalyst layer slurry preparation method, catalyst slurry and application thereof

A fuel cell electrode and catalyst slurry technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of unreasonable electrode catalytic layer and gas diffusion layer structure, high resistance to reaction gas and liquid water transfer, and difficulty in large-scale batch production Production and other problems, to achieve the effect of high particle size distribution consistency, not easy to aggregate, wide range of adjustable viscosity and viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

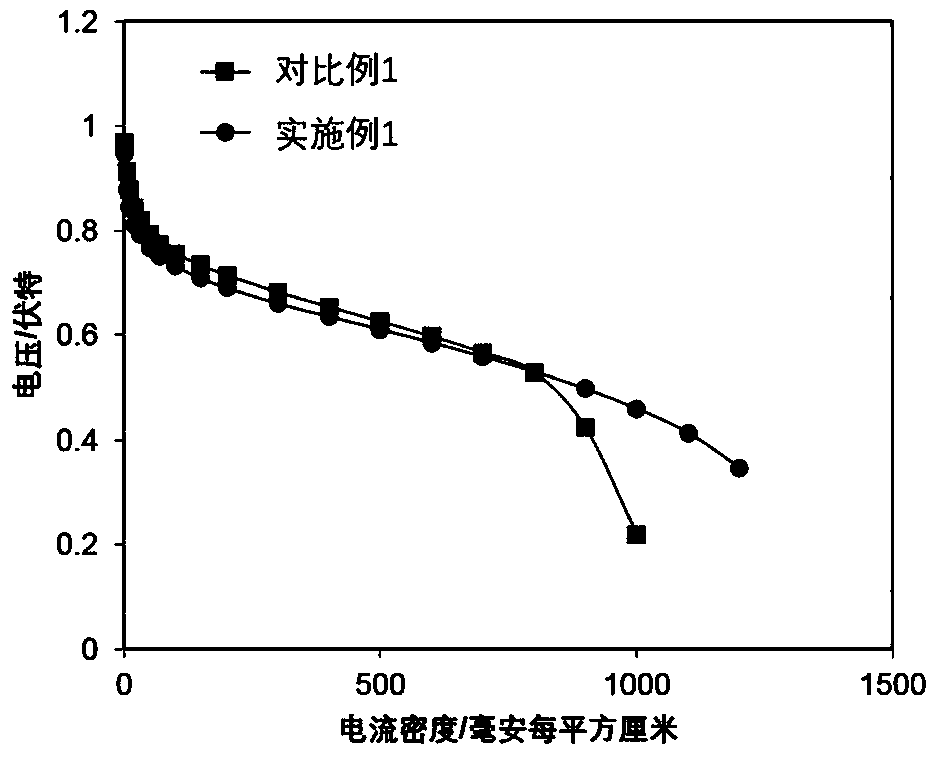

Embodiment 1

[0038] a, pretreatment of catalyst:

[0039] Fully wet the Pt / C (60%) catalyst powder used in the electrode with 2 times of deionized water, add a mixed solution of water and ethanol with a mass ratio of 1:5, the mass is 5 times that of the catalyst, and disperse with ultrasonic stirring 1 hour until uniform; add polybenzimidazole and polytetrafluoroethylene 1:1 additive, the mass is 0.3 times that of the catalyst, and fully ultrasonically stir for 2 hours until uniform to obtain a mixed slurry; add dimethylformamide with a mass of 50 times the mixed slurry base formamide solvent, reflux and stir at 120 degrees centigrade for 5 hours; filter after natural cooling, and keep the filter cake for subsequent use;

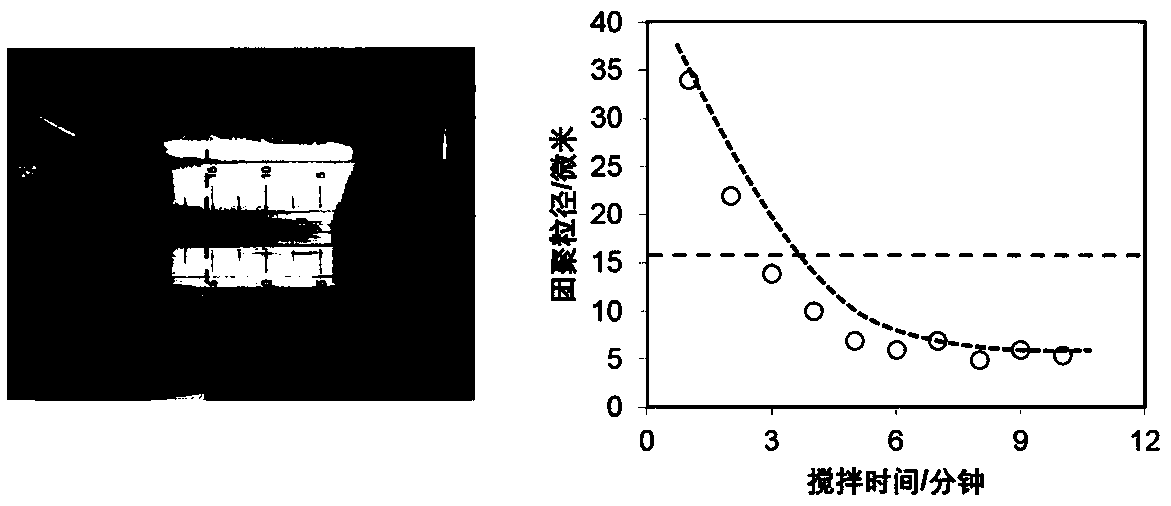

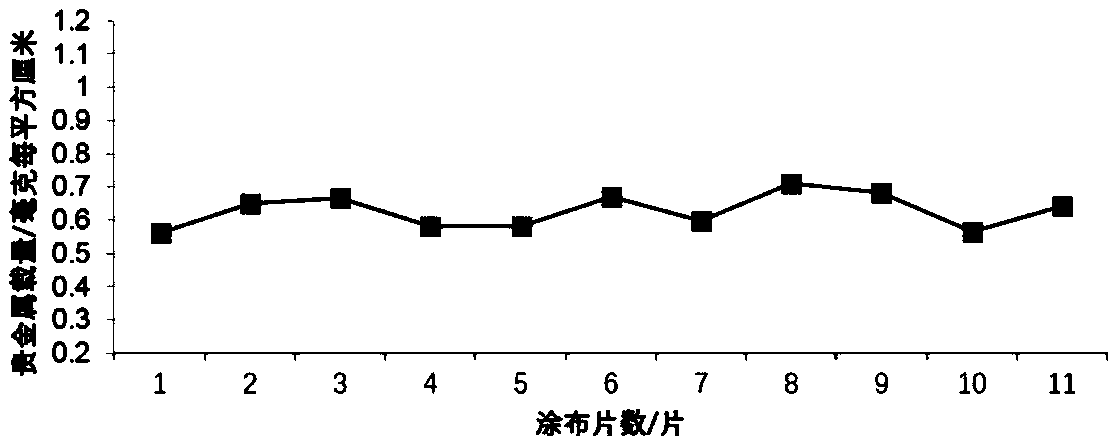

[0040] b, preparation of catalyst slurry

[0041] Add the filter cake obtained in step a to water with 5 times the mass of the catalyst, and ultrasonically stir evenly; add methanol with 5 times the mass of the catalyst, and stir ultrasonically; add dimethylacetamide wi...

Embodiment 2

[0063] a, pretreatment of catalyst:

[0064] Fully wet the PtCo / C (50%) catalyst powder used in the electrode with 1 times deionized water, add a mixed solution of water and cyclohexane with a mass ratio of 1:1, the mass is 10 times that of the catalyst, and ultrasonically Stir and disperse for 4 hours until uniform; add a mixture of sodium dodecylbenzenesulfonate and perfluorosulfonic acid polymer with a molar ratio of 1:1, the mass of which is 0.05 times that of the catalyst, and fully ultrasonically stir for 2 hours until uniform to obtain a mixed slurry; Add a formamide solvent whose mass is 50 times that of the mixed slurry, reflux and stir at 100 degrees Celsius for 4 hours; filter after natural cooling, and keep the filter cake for later use;

[0065] b, preparation of catalyst slurry

[0066] Add the filter cake obtained in step a to water with 2 times the mass of the catalyst, and ultrasonically stir evenly; add acetone with 3 times the mass of the catalyst, and ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com