Additive for soybean meal fermentation and application of additive in feed

An additive, soybean meal technology, applied in the application, animal feed, animal feed and other directions, can solve the problems that the compound enzyme bacteria preparation is difficult to play, the bacteria-enzyme dosage is large, and the fermentation period is long, so as to improve the digestibility of animal nutrition, The effect of short process cycle and reduction of material-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

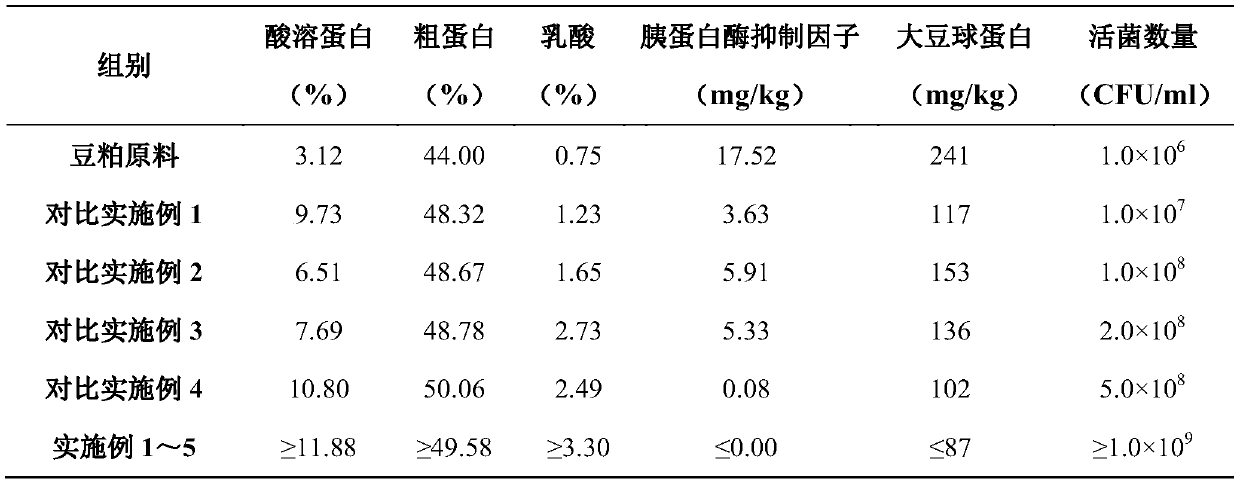

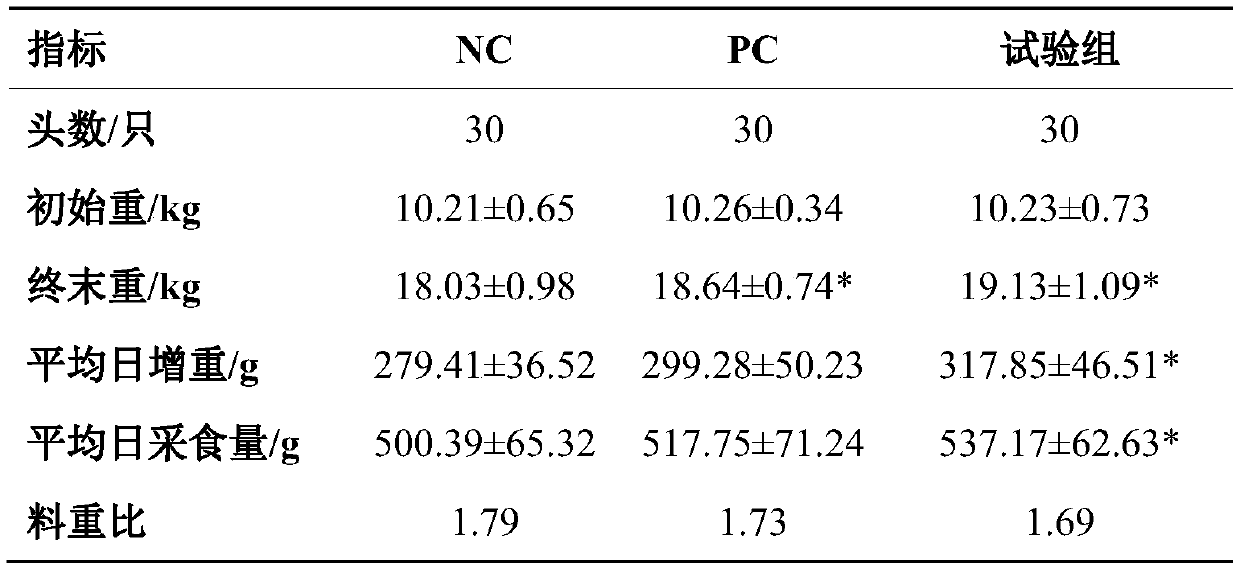

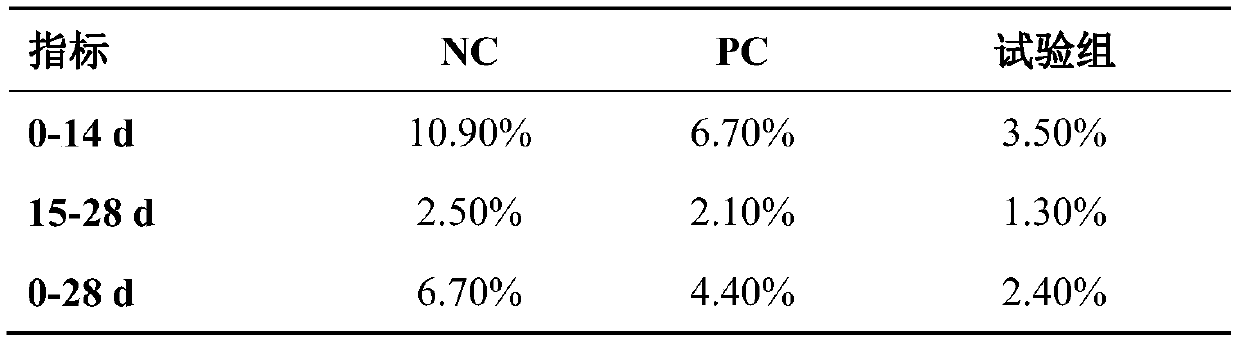

Examples

Embodiment 1

[0029] An additive for soybean meal fermentation, including composite microorganisms and composite proteases, wherein the composite microorganisms consist of 3.0×10 9 CFU / g of Saccharomyces cerevisiae, 1.0×10 9 CFU / g of Streptococcus faecalis and 2.0×10 9 CFU / g of lactobacillus; the protease consists of 150000U / g of acid protease, 200000U / g of alkaline protease and 80000U / g of neutral protease.

[0030] A fermented soybean meal prepared by the following method:

[0031] (1) Add the compound protease and the compound microorganism into the aqueous solution, then add glucose, mix and stir until dissolved, and obtain the mixed solution of activated enzyme bacteria; the compound protease preparation, compound microorganism preparation, purified water, and glucose are in the ratio of 0.15:0.5: 250:5;

[0032] (2) Inoculate the activated enzyme-bacteria mixture into the soybean meal raw material at a ratio of 0.5:1, stir and mix evenly, and then seal and ferment at 35-37°C for 45...

Embodiment 2

[0035] An additive for soybean meal fermentation, including composite microorganisms and composite proteases, wherein the composite microorganisms consist of 3.0×10 9 CFU / g of Saccharomyces cerevisiae, 2.0×10 9 CFU / g of Streptococcus faecalis and 2.0×10 9 CFU / g of lactobacillus; the composite protease is composed of 160000U / g of acid protease, 200000U / g of alkaline protease and 120000U / g of neutral protease.

[0036] A fermented soybean meal prepared by the following method:

[0037] (1) Add the compound protease and compound microorganism into the aqueous solution, then add glucose, mix and stir until dissolved, and obtain the mixed solution of activated enzyme bacteria; compound protease, compound microorganism, purified water, and glucose are in proportion of 0.15:0.5:300: 10;

[0038] (2) Inoculate the activated enzyme-bacteria mixture into soybean meal at a ratio of 0.6:1, stir and mix evenly, and then seal and ferment at 35-37°C for 45-50 hours to obtain a fermented s...

Embodiment 3

[0041] An additive for soybean meal fermentation, including composite microorganisms and composite proteases, wherein the composite microorganisms consist of 4.0×10 9 CFU / g of Saccharomyces cerevisiae, 1.0×10 9 CFU / g of Streptococcus faecalis and 2.0×10 9 CFU / g of lactobacillus; the composite protease is composed of 150,000 U / g of acid protease, 200,000 U / g of alkaline protease and 110,000 U / g of neutral protease.

[0042] A fermented soybean meal prepared by the following method:

[0043] (1) Add the compound protease and the compound microorganism into the aqueous solution, then add glucose, mix and stir until dissolved, and obtain the mixed solution of activated enzyme bacteria; the compound enzyme preparation, the compound bacterial agent, purified water, and glucose are in proportion of 0.15:0.55: 250:5;

[0044] (2) Inoculate the activated enzyme-bacteria mixture into the soybean meal raw material at a ratio of 0.5:1, stir and mix evenly, and then seal and ferment at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com