Method for synthesizing nano K, Ca-CHA zeolite

A zeolite and nanotechnology, applied in the field of preparation of nano K, Ca-CHA zeolite, can solve the problems of application limitation, loss of molecular shape-selective adsorption properties and catalytic properties, difficulty in reflecting the value of molecular sieve adsorption and catalytic properties, etc., reaching the price Effects of low cost, abundant reserves, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

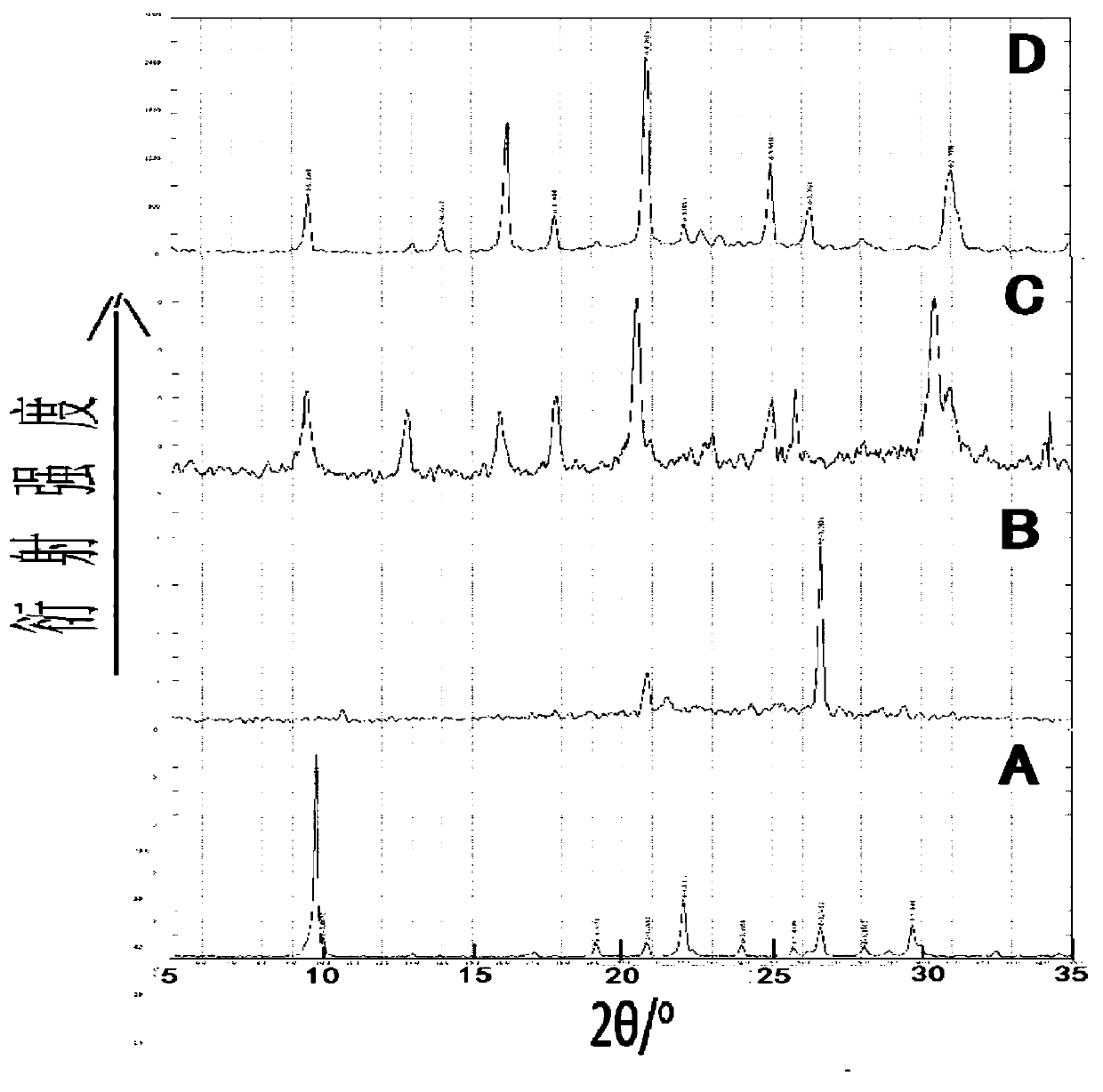

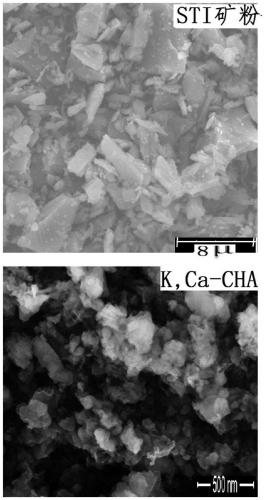

[0056] Add 50g of roasted STI ore powder and 2.5g of CHA zeolite seed crystals into 450ml of KOH aqueous solution with a concentration of 1.0mol / L, stir vigorously at room temperature for 2 hours and mix them uniformly as reactants. The reactants are poured into 750ml of pressure-resistant stainless steel Put it in a reaction kettle, seal it, place it in a homogeneous reaction oven at 130°C, react under dynamic conditions for 48 hours, take it out, cool it, filter it, wash it with deionized water until the filtrate pH=7-8, then filter it and dry it . The product is identified as CHA crystalline phase through XRD (see figure 2 C). With the XRD powder diffraction spectrum (see figure 2 D) In comparison, the position of the diffraction peak slightly shifts to a larger angle, which is due to the lower SAR of the product synthesized in Example 1, which causes the unit cell to shrink somewhat compared to the unit cell of the H-CHA zeolite standard sample. Table 3 lists the XR...

Embodiment 2

[0060] Add 50g of roasted STI ore powder and 2.5g of CHA zeolite seed crystals into 450ml of KOH aqueous solution with a concentration of 1.0mol / L, stir vigorously at room temperature for 2 hours, mix well and use it as a reactant, and pour the reactant into a 750ml pressure-resistant In a stainless steel reaction kettle, sealed, placed in a homogeneous reaction oven at 150°C, reacted under dynamic conditions for 48 hours, taken out, cooled, filtered, washed with deionized water until the filtrate PH = 7-8, then filtered and dried Dry. The product was identified as CHA crystalline phase by XRD. Table 3 lists the XRF component analysis data of the reaction raw material roasted STI ore powder and the product of Example 2. The SARs of the reaction product and mineral powder raw material are 5.43 and 5.54, which are very close. The content of the two MgO raw materials is 0.19% and the product is 0.0%, which is also almost the same. The content of CaO in the product is 6.35%, wh...

Embodiment 3

[0062] Add 50g of roasted STI ore powder and 2.5g of CHA zeolite seed crystals into 450ml of KOH aqueous solution with a concentration of 2.0mol / L, stir vigorously at room temperature for 2 hours, mix well and use it as a reactant, and pour the reactant into a 750ml pressure-resistant In a stainless steel reaction kettle, sealed, placed in a homogeneous reaction oven at 150°C, reacted under dynamic conditions for 48 hours, taken out, cooled, filtered, washed with deionized water until the filtrate PH = 7-8, then filtered and dried Dry. The product was identified as CHA crystalline phase by XRD. Table 3 lists the XRF component analysis data of the reaction raw material roasted STI ore powder and the product of Example 2. The SARs of the reaction product and mineral powder raw material were 6.42 and 5.43, higher than the latter. The MgO contents of the products are 0.0% and 0.19%, respectively, which are also almost the same. The content of CaO in the product is 7.74%, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com