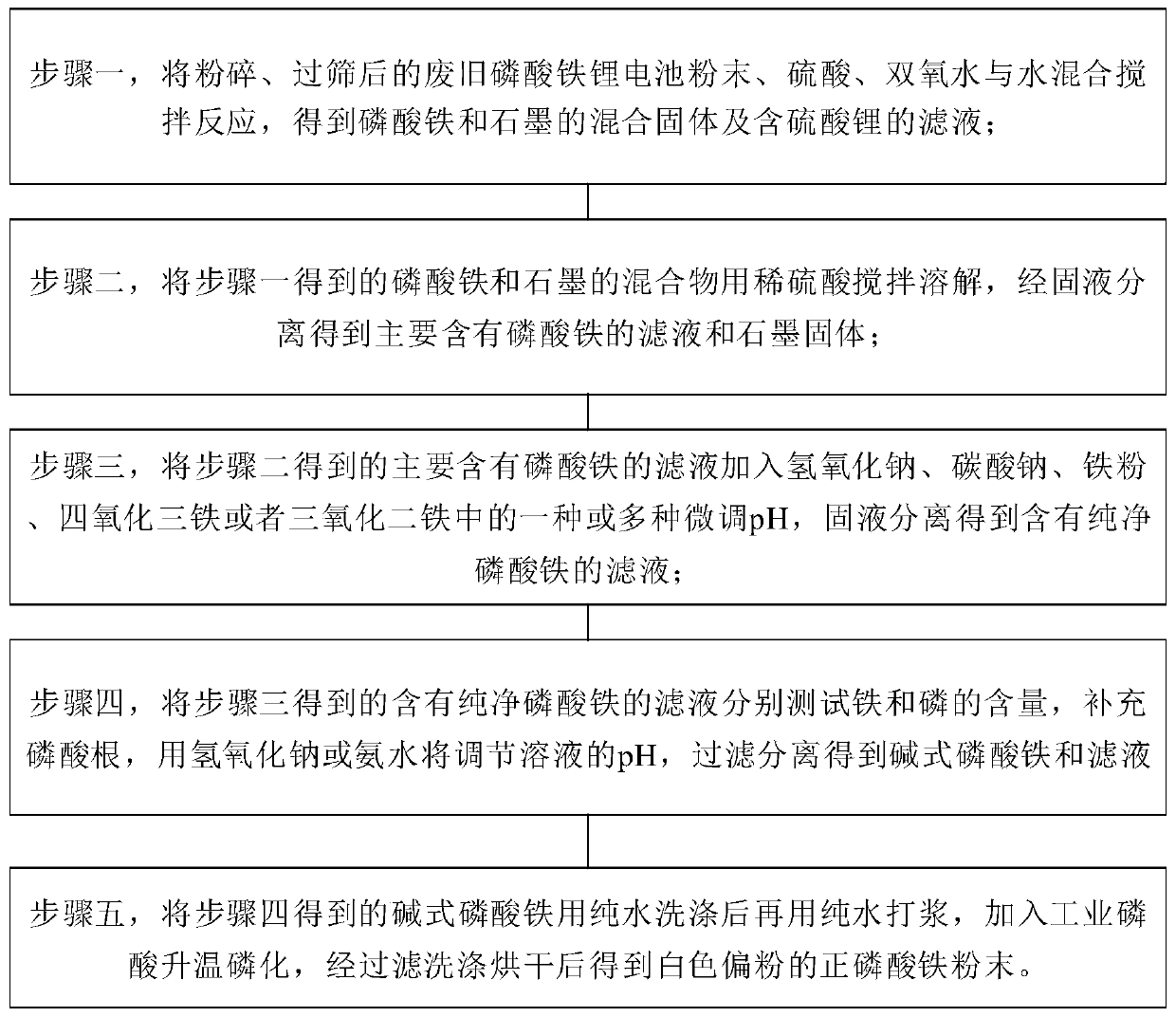

Method for extracting battery-grade iron phosphate from waste lithium iron phosphate battery

A lithium iron phosphate battery and iron phosphate technology, applied in battery electrodes, battery recycling, chemical instruments and methods, etc., can solve the problems of not meeting the standards of iron phosphate raw materials, high iron phosphate impurities, waste of iron and phosphorus, etc., and achieve pressure High solid density, high energy density, good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw material in this embodiment is lithium iron phosphate cathode powder, has explored many groups of different acid leaching processes (acid dosage, acid concentration, acid leaching time and temperature), different impurity removal conditions (different pH and temperature), different Basic ferric phosphate synthesis process (pH of synthetic ferric phosphate, reaction time, etc.), different phosphating conditions (acid dosage, reaction time, etc.).

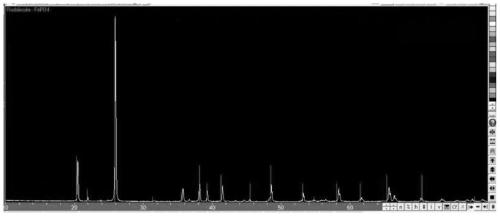

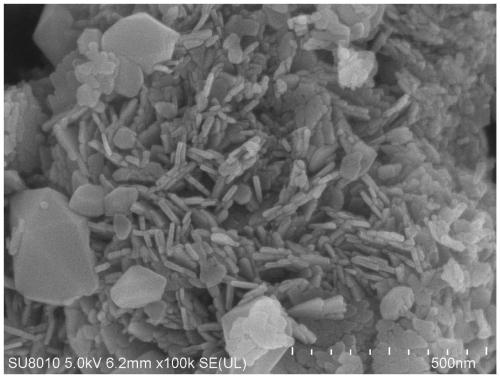

[0028] Take the optimal extraction process as an example: the optimal solid-liquid ratio of oxidative acid leaching is 1:3, and the amount of hydrogen peroxide is twice the theoretical amount. The sulfuric acid concentration for pickling is 16%, the solid-liquid ratio is 1:5.7, the temperature is 60°C, and the reaction time is 2h. The optimum pH for impurity removal is 1.8, and the optimum temperature is 80°C. The ratio of synthetic iron and phosphorus is 1:1.2, and the reaction temperature is 50°C. The optimum tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com