Method for recovering waste iron-molybdenum catalyst for preparing formaldehyde through methanol oxidation

A technology for recycling methanol and catalysts, which is applied in the field of recycling waste catalysts for the oxidation of iron-molybdenum-based methanol to formaldehyde, which can solve the problems of high cost and difficulty, and achieve the effects of convenient operation, high recovery rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The spent catalyst was separated by centrifugation, sieved, and calcined at 500°C for four hours, and sampled and analyzed the composition of the catalyst by XRF. Then take 100g of the catalyst after removal of impurities, pulverize and grind it, add 610.76g of 5.03wt% ammonia water into a closed reactor, stir at 103℃ for 10h, filter, and wash the filter cake with 60℃ ammoniated water (pH=9.0). , 300ml each time, wash three times. The filter cake was washed with pure water at 60℃ for the last time. The pH of the fourth washing liquid was 7.73 / 50℃, and the conductivity was 1.9 ms / cm. It was tested that there was no Mo in the fourth washing liquid. 6+ . Collect the filtrate and the first three washing liquids, heat up to 85℃ and steam ammonia for 3.5h under medium-speed stirring, and steam to pH=5.91 / 80℃ to stop the ammonia distillation, and prepare the ammonia solution to Mo 6+ A solution with a concentration of 0.25 mol / L.

[0042] To Fe(OH) 3 Add 49% HNO 3 Make the mixed...

Embodiment 2

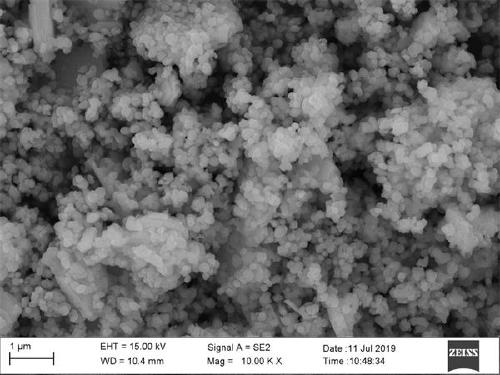

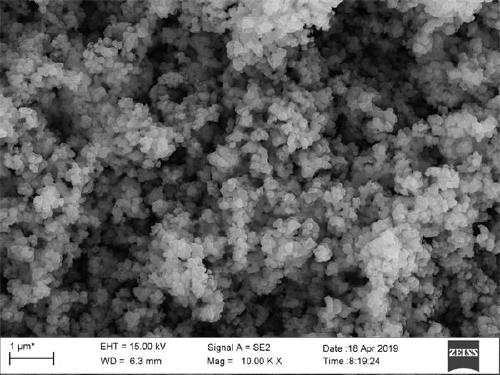

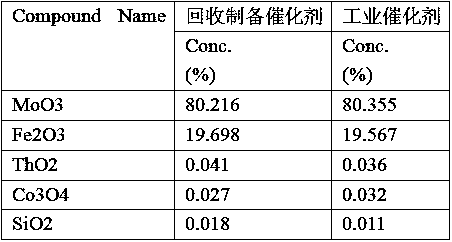

[0045] The iron salt and molybdenum salt solutions obtained in Example 1 were co-precipitated at a certain temperature, aged, dried, shaped, and roasted at a high temperature to obtain a methanol oxidation to formaldehyde catalyst product. The recovered catalyst is comparable to the existing industrial methanol oxidation to formaldehyde catalyst in terms of crystal form, component content and performance evaluation results. The analysis and evaluation results are as follows:

[0046] Recovery preparation catalyst

[0047]

[0048] The catalytic performance evaluation conditions and results of the catalyst are as follows

[0049] Evaluation conditions:

[0050] Catalyst filling: 20-40 mesh, filling volume 3ml, sv=24000h -1 , Reaction pressure=0.075Mpa, reaction gas 15% O 2 , The rest N 2 , Methanol feed concentration (mol) 6.5%

[0051] Evaluation results

[0052]

[0053] Note: The above are the laboratory evaluation data for the recovery and preparation of catalysts and industrial cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com