Polyimide flexible copper-clad plate

A technology of polyimide flexibility and polyimide, which is applied in the field of polyimide flexible copper clad laminates, can solve the problems that the performance of 2F-FCCL cannot meet the demand, and achieve excellent performance, small size change, and dielectric strength. The effect of low coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

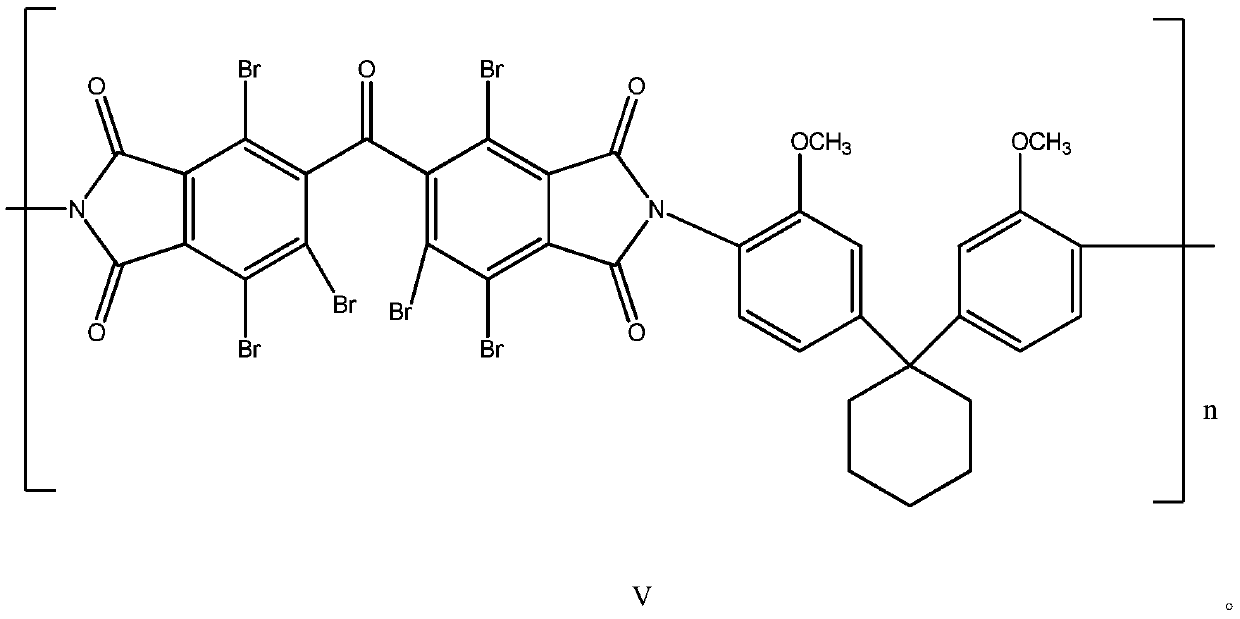

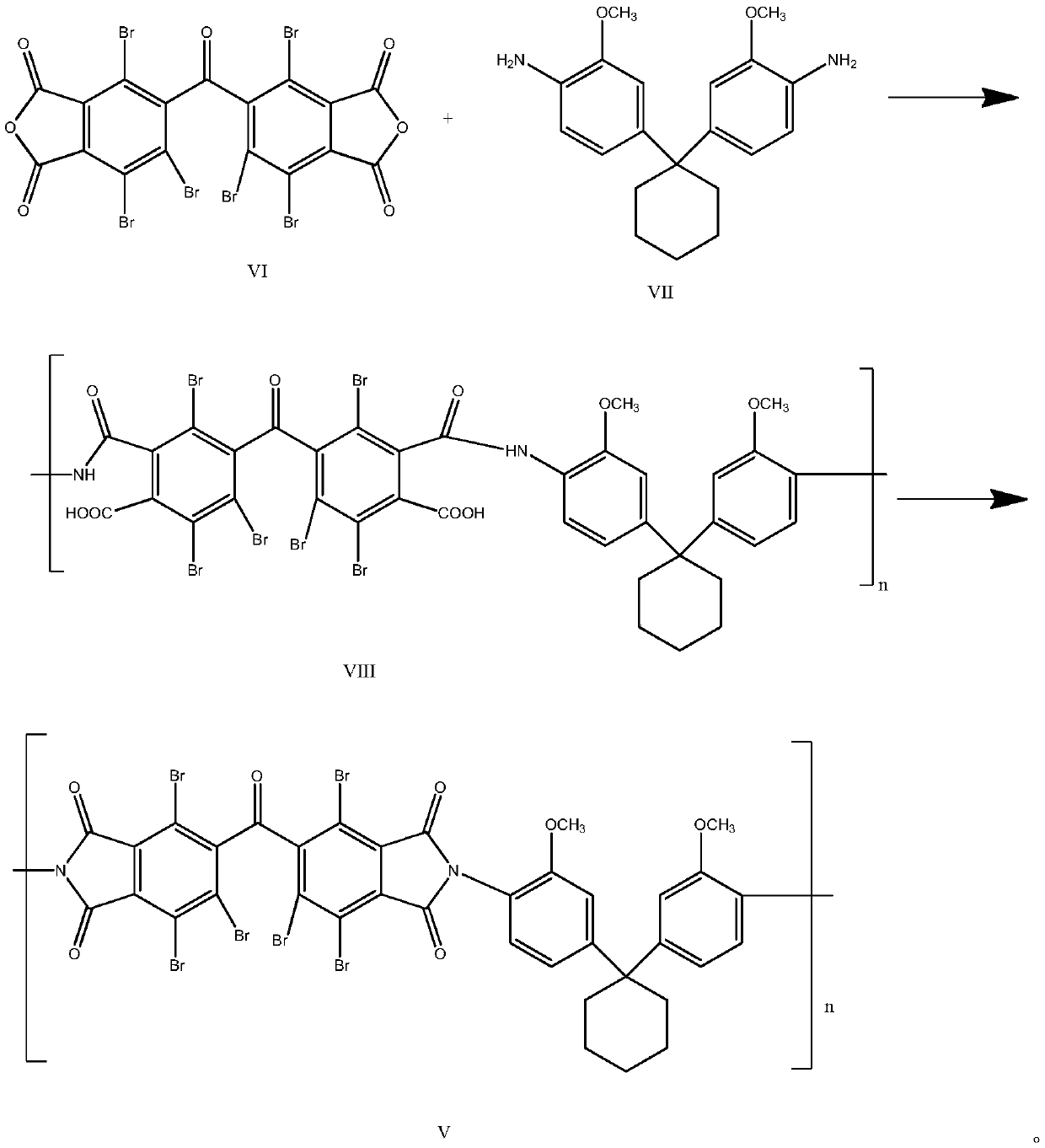

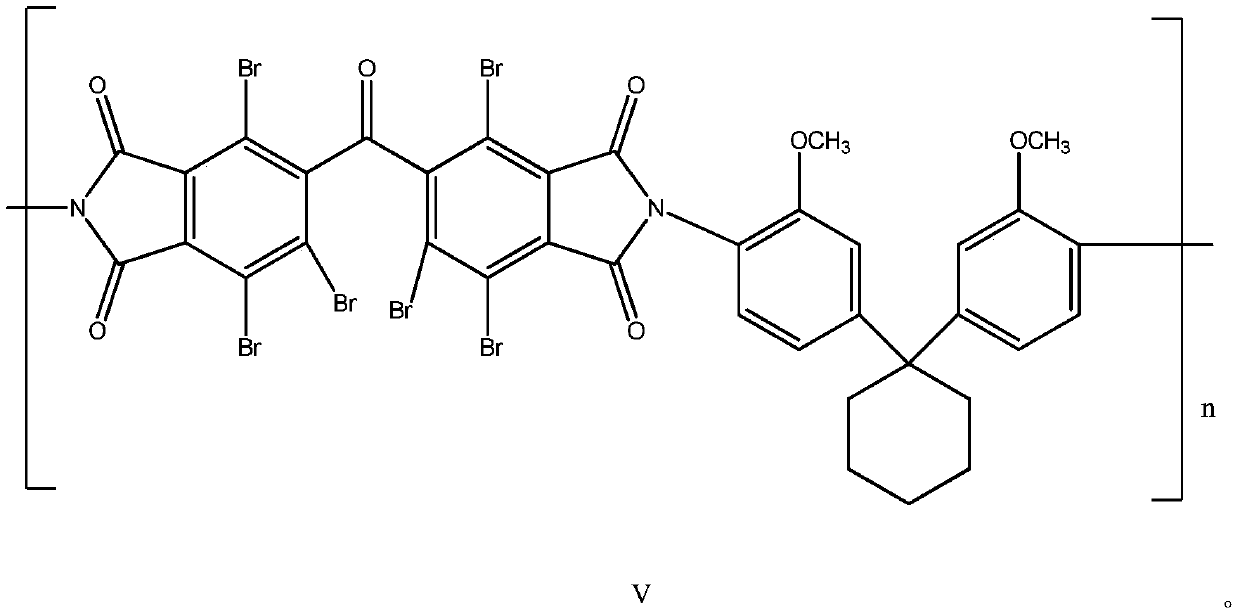

[0033] The preparation method of low dielectric polyimide comprises the following steps:

[0034] (1) Under nitrogen protection and a certain temperature condition, the compound shown in the formula VI and the compound shown in the formula VII are stirred and reacted in an organic solvent to obtain the intermediate shown in the formula VIII; the organic solvent is N-methyl Pyrrolidone; the reaction temperature is 15°C;

[0035] (2) add dehydrating agent and catalyzer, the intermediate shown in VIII continues stirring reaction at a certain temperature, cleans, filters, dries, obtains the compound shown in formula V; Described dehydrating agent is trifluoroacetic anhydride; Dehydrating agent The molar ratio of the catalyst to the compound VII is 4:1; the catalyst is triethylamine, and the molar ratio of the catalyst to the compound VII is 3:1; the reaction temperature is 50°C.

[0036] Polymer molecular structure evaluation method: Fourier transform infrared spectroscopy (FT-IR...

Embodiment 2

[0039] The preparation method of low dielectric polyimide comprises the following steps:

[0040] (1) Under nitrogen protection and a certain temperature condition, the compound shown in the formula VI and the compound shown in the formula VII are stirred and reacted in an organic solvent to obtain the intermediate shown in the formula VIII; the organic solvent is N, N- Dimethylacetamide; the reaction temperature is 5°C;

[0041] (2) add dehydrating agent and catalyzer, the intermediate shown in VIII continues stirring reaction at a certain temperature, cleans, filters, dries, obtains the compound shown in formula V; Described dehydrating agent is acetic anhydride; Dehydrating agent and compound The molar ratio of VII is 5:1; the catalyst is pyridine, and the molar ratio of catalyst to compound VII is 4:1; the reaction temperature is 40°C.

Embodiment 3

[0043] The preparation method of low dielectric polyimide comprises the following steps:

[0044] (1) Under nitrogen protection and a certain temperature condition, the compound shown in the formula VI and the compound shown in the formula VII are stirred and reacted in an organic solvent to obtain the intermediate shown in the formula VIII; the organic solvent is N, N- Dimethylformyl; the reaction temperature is 25°C;

[0045] (2) add dehydrating agent and catalyzer, the intermediate shown in VIII continues stirring reaction at a certain temperature, washes, filters, dries, obtains the compound shown in formula V; Described dehydrating agent is sulfur oxychloride; Dehydrating agent The molar ratio of the catalyst to the compound VII is 3:1; the catalyst is triethylamine, and the molar ratio of the catalyst to the compound VII is 2:1; the reaction temperature is 60°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com