Lithium-magnesium-niobium-aluminum-tungsten microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and lithium magnesium niobium, which is applied in the field of ceramic materials, can solve the problems of high loss of microwave dielectric ceramics, achieve the effects of promoting growth, wide application prospects, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

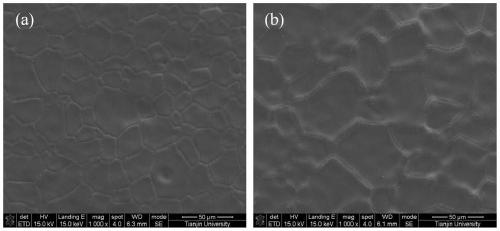

Image

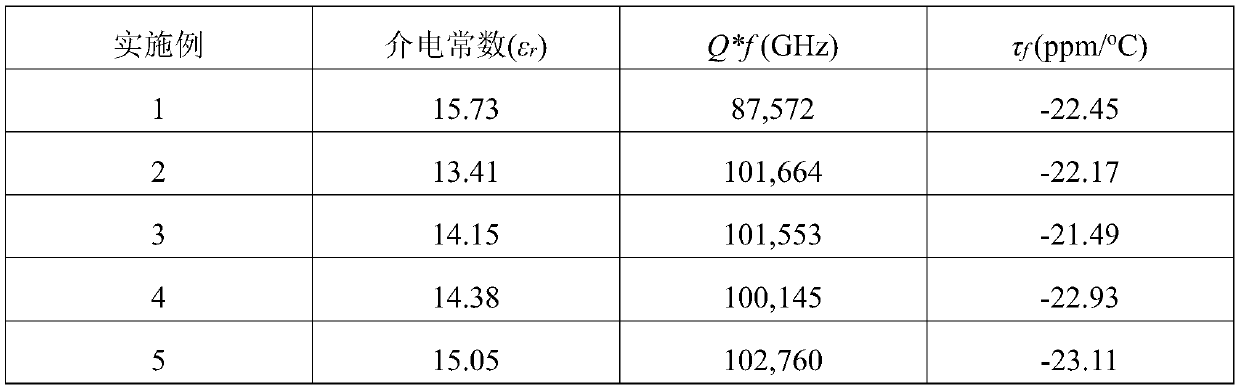

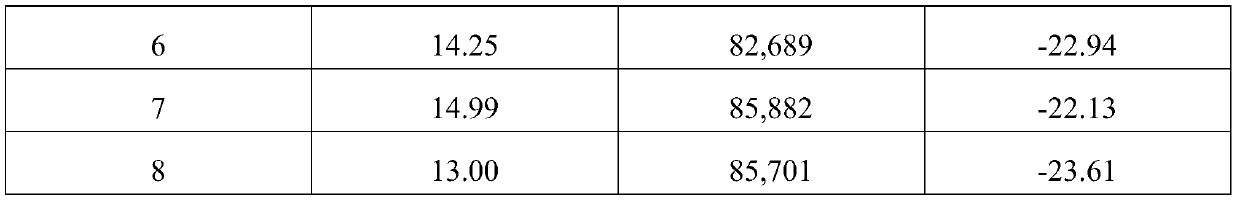

Examples

Embodiment 1

[0029] 1. According to the microwave dielectric ceramic composition Li 3 Mg 2 Nb 0.98 (Al 1 / 3 W 2 / 3 ) 0.02 O 6 , Called Li 2 CO 3 -6.8181g, MgO-4.9587g, Nb 2 O 5 -8.0121g, Al 2 O 3 -0.0209g, WO 3 -0.1902g ingredients, 20g in total; put the mixed raw materials into a nylon tank, add 160ml deionized water and 150g zirconium balls, and then ball mill on a planetary ball mill for 4 hours at a speed of 250 rpm;

[0030] 2. Place the ball milled raw materials in a drying box for drying and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0031] 3. Pre-fire the powder at 925°C and keep it warm for 4 hours;

[0032] 4. Put the pre-burned powder into a nylon tank, add deionized water and zirconium balls, and mill it again for 8 hours. After the material is discharged, it is dried and passed through a 40-mesh sieve; paraffin wax with a mass ratio of 8 wt% is added as a binder. Granulate, then pass through an 80-mesh sieve; then press the powder into a green body with a...

Embodiment 2

[0036] 1. According to the microwave dielectric ceramic composition Li 3 Mg 2 Nb 0.96 (Al 1 / 3 W 2 / 3 ) 0.04 O 6 , Called Li 2 CO 3 -6.8020g, MgO-4.9469g, Al 2 O 3 -0.0417g, WO 3 -0.3794g of ingredients, 20g in total; add the mixed raw materials into a nylon tank, add 160ml of deionized water and 150g of zirconium balls, and mill them on a planetary ball mill for 8 hours at a speed of 250 rpm;

[0037] 2. Place the ball milled raw materials in a drying box for drying and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0038] 3. Pre-burn the powder at 950℃ and keep it warm for 6 hours;

[0039] 4. Put the pre-burned powder into a nylon tank, add deionized water and zirconium balls, and then ball mill for 6 hours. After the material is discharged, it is dried and passed through a 40-mesh sieve; paraffin wax with a mass ratio of 8wt% is added as a binder. Granulate, then pass through an 80-mesh sieve; then press the powder into a green body with a diameter of 10m...

Embodiment 3

[0043] 1. According to the microwave dielectric ceramic composition Li 3 Mg 2 Nb 0.96 (Al 1 / 3 W 2 / 3 ) 0.04 O 6 , Called Li 2 CO 3 -6.8020g, MgO-4.9469g, Al 2 O 3 -0.0417g, WO 3 -0.3794g of ingredients, 20g in total; add the mixed raw materials into a nylon tank, add 160ml of deionized water and 150g of zirconium balls, and then ball mill on a planetary ball mill for 6 hours at a speed of 250 rpm;

[0044] 2. Place the ball milled raw materials in a drying box for drying and pass through a 40-mesh sieve to obtain a powder with uniform particles;

[0045] 3. Pre-burn the powder at 975°C and keep it warm for 4 hours;

[0046] 4. Put the pre-burned powder into a nylon tank, add deionized water and zirconium balls, and then ball mill for 6 hours. After the material is discharged, it is dried and passed through a 40-mesh sieve; paraffin wax with a mass ratio of 8wt% is added as a binder. Granulate, then pass through an 80-mesh sieve; then press the powder into a green body with a diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com