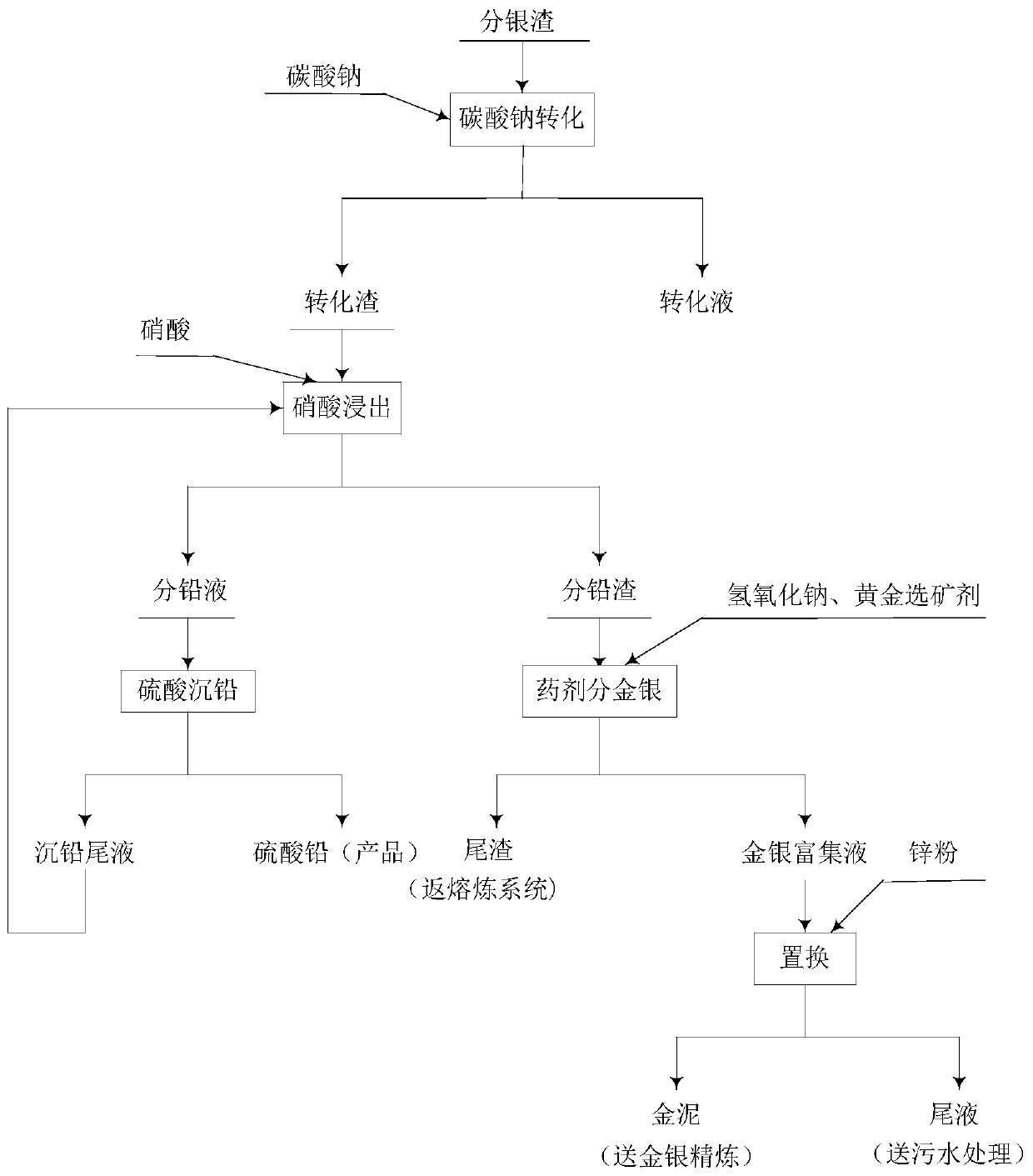

Method for recovering lead, gold and solver from silver separation slag

A technology for separating silver slag and sinking lead, which is applied in the field of copper smelting, can solve problems such as increased quality impact, low economic value, and demanding process conditions, and achieve the effects of no environmental pollution, simple process operation, and optimized process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The main components of the silver-separating slag are (by weight): 0.0038% of Au, 0.573% of Ag, and 32.03% of Pb. Take by weighing 800g of the above-mentioned silver separation slag, add it into the beaker according to the liquid-solid ratio of 3:1, then add a sodium carbonate solution with a concentration of 0.75mol / L in the beaker, stir for 1 hour at normal temperature and normal pressure, filter, and obtain the conversion liquid and 782g conversion residue. After testing, the conversion liquid contained 0.021g / L of lead. Main components of conversion slag (by weight percentage): Au 0.0038%, Ag 0.586%, Pb 32.40%.

[0026] Under the condition of normal temperature and normal pressure, add the above 782g of conversion slag into the beaker according to the liquid-solid ratio of 3:1, and start stirring. While stirring, add nitric acid dropwise, until the pH of the solution is ≤1, stop adding nitric acid dropwise. After reacting for 1 hour, filter and wash to obtain 318g...

Embodiment 2

[0030] The main components of the silver separating slag are (by weight percentage): Au 0.0035%, Ag 0.56%, Pb 32.09%. Take by weighing 800g of the above-mentioned silver slag, add it to the beaker at a liquid-solid ratio of 5:1, then add a sodium carbonate solution with a concentration of 0.94mol / L to the beaker, stir for 2 hours at normal temperature and pressure, filter to obtain the conversion solution and 764g of conversion residue. After testing, the conversion liquid contained 0.021g / L of lead. Main components of conversion slag (by weight percentage): Au 0.0040%, Ag 0.60%, Pb 33.16%.

[0031] Under normal temperature and normal pressure conditions, add 764g of the above-mentioned conversion slag into the beaker according to the liquid-solid ratio of 4:1, and start stirring. While stirring, add nitric acid dropwise, and stop adding nitric acid dropwise until the pH of the solution is ≤1. After reacting for 2 hours, filter and wash to obtain 225g of lead slag and 4550ml...

Embodiment 3

[0035] The main components of the silver-separating slag are (by weight): 0.0034% of Au, 0.56% of Ag, and 33.03% of Pb. Take by weighing 800g of the above-mentioned silver-separating slag, add it to the beaker according to the liquid-solid ratio of 6:1, then add a sodium carbonate solution with a concentration of 0.94mol / L in the beaker, stir for 4 hours at normal temperature and normal pressure, filter, and obtain the conversion liquid and 754g of conversion residue. After testing, the conversion liquid contained 0.021g / L of lead. Main components of conversion slag (by weight percentage): Au 0.0038%, Ag 0.586%, Pb 32.40%.

[0036] Under the condition of normal temperature and normal pressure, add the above 754g of conversion slag into the beaker according to the liquid-solid ratio of 6:1, and start stirring. While stirring, add nitric acid dropwise, until the pH of the solution is ≤1, stop adding nitric acid dropwise. After reacting for 3 hours, filter and wash to obtain 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com