Chromium-free tinning plate and surface treatment method thereof

A tin plate and tin plate technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems such as insufficient environmental protection and environmental pollution, to ensure the effect of lamination, avoid temperature fluctuations, and maintain use. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

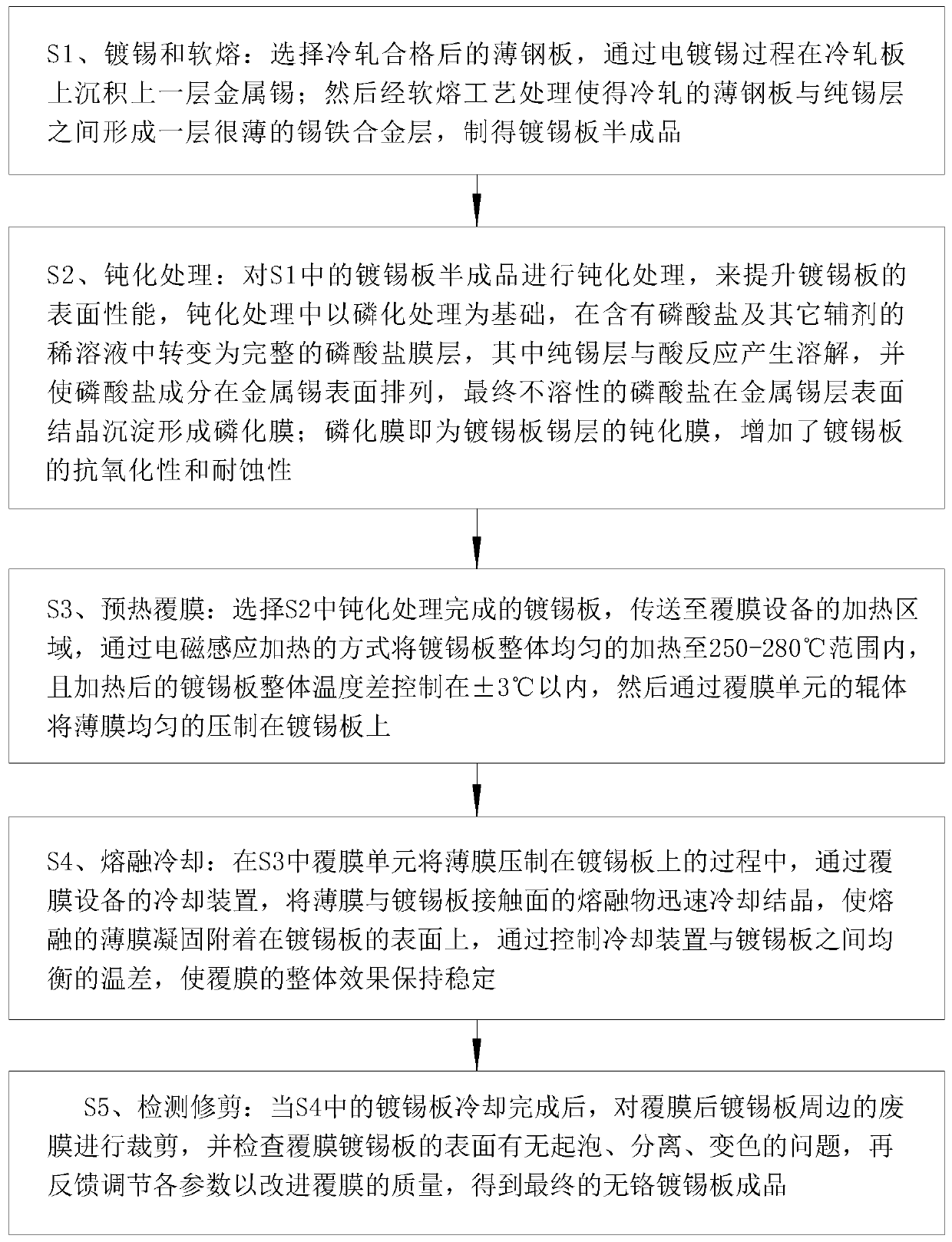

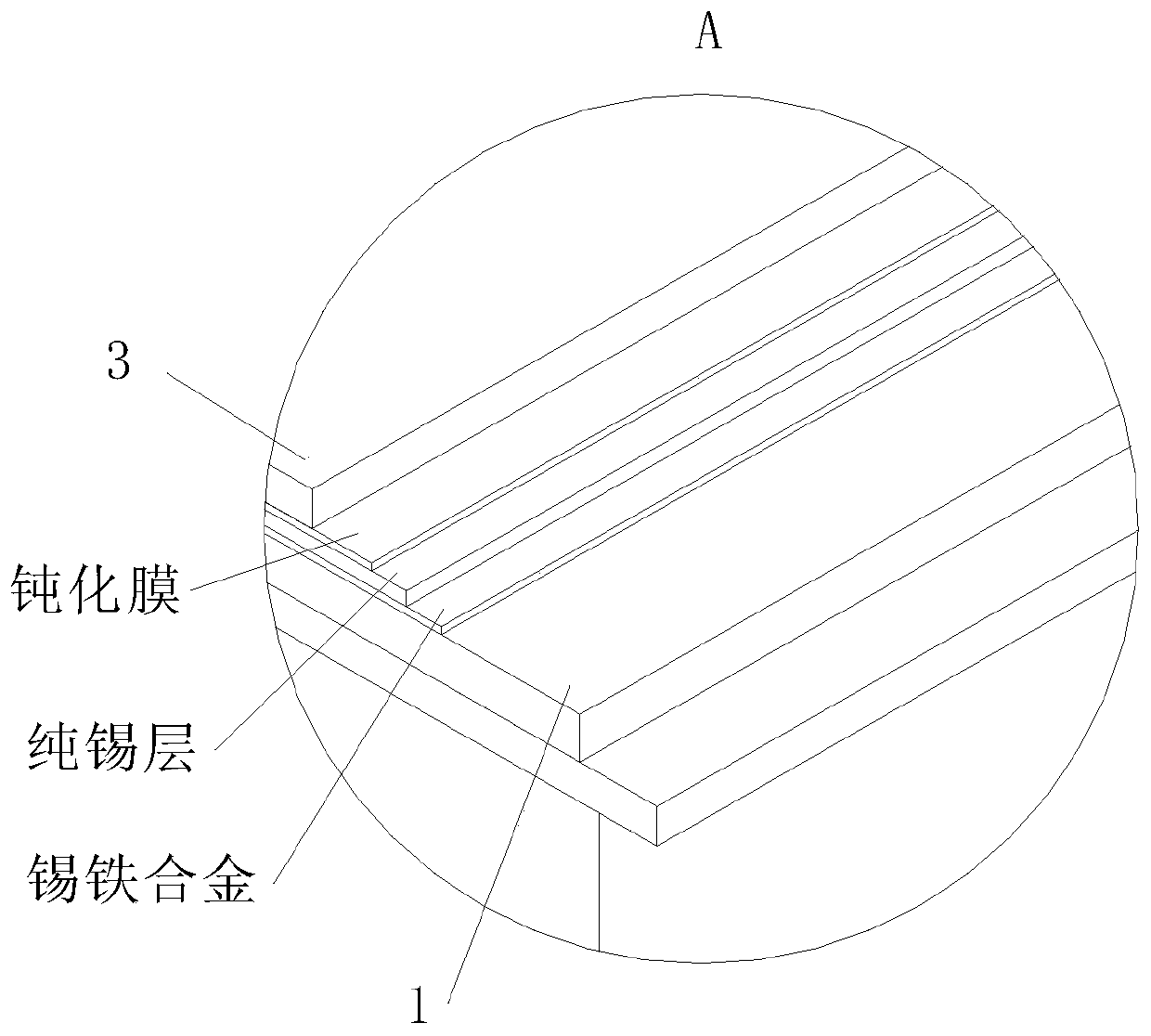

Method used

Image

Examples

Embodiment approach

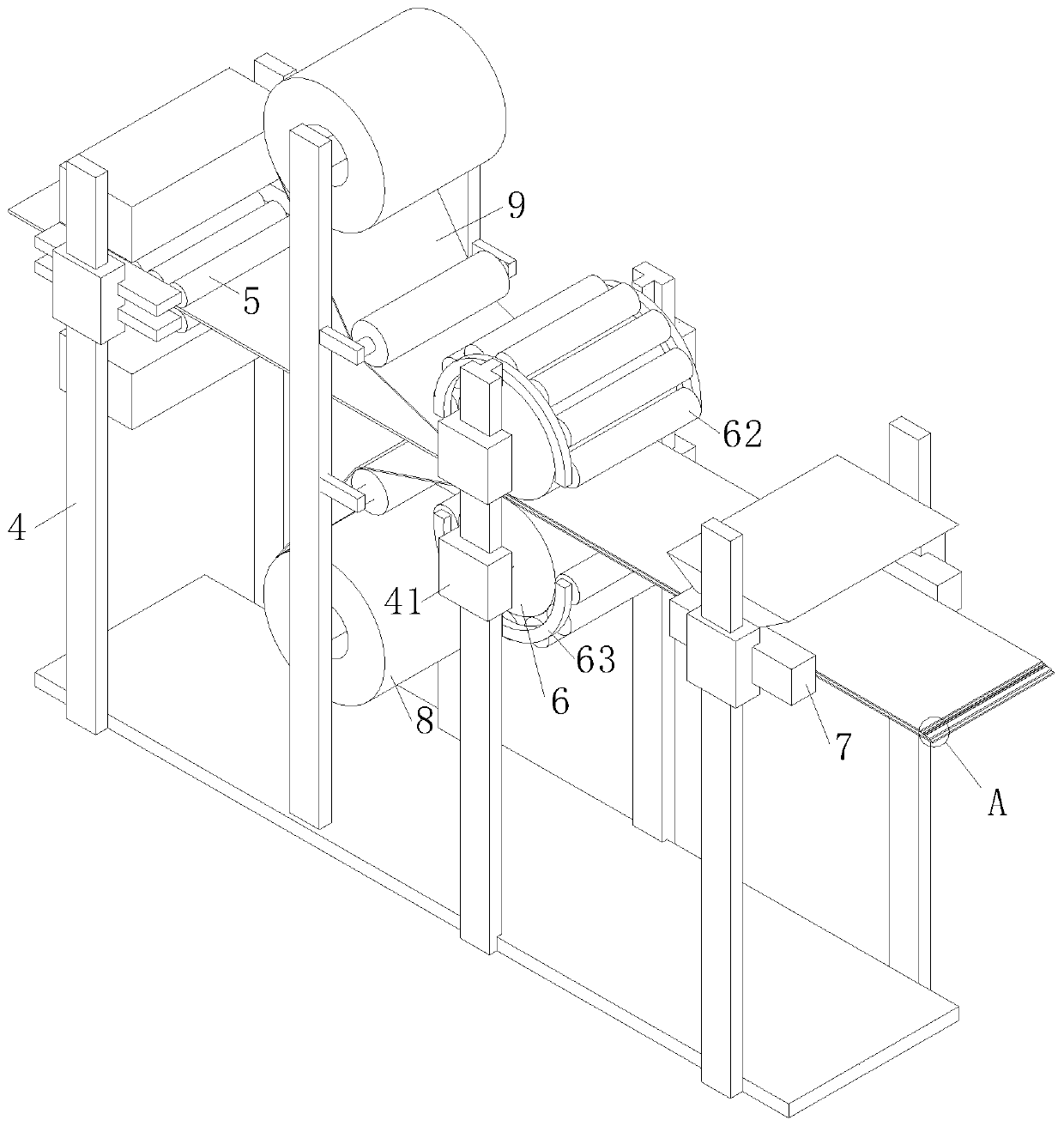

[0031] As an embodiment of the present invention, the laminating roller 6 is provided with a cooling roller 62, the cooling roller 62 is distributed around the semicircle of the laminating roller 6, and the cooling roller 62 is in rolling contact with the laminating roller 6. , cooling roll 62 is provided with ring frame 63, and cooling roll 62 links to each other with support 4 through ring frame 63; The rolling contact makes the temperature of the surface of the laminating roller 6 gradually increase, but the laminating roller 6 after the temperature rise cannot produce a sufficient temperature difference to cool and crystallize the plastic film 9, thereby stabilizing the coating of the tinplate. weakened; through the cooling roller 62 arranged on the laminating roller 6, the rolling contact between the cooling roller 62 and the laminating roller 6 will quickly dissipate the heat conducted to the tin plate on the laminating roller 6, keeping the pressure The temperature diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com