Method for treating waste gas of refined terephthalic acid sewage plant

A purified terephthalic acid and treatment method technology, applied in the field of waste gas treatment, can solve the problems of high investment and operation cost, high operation cost, and general treatment effect, and achieve low investment and operation cost, simple operation and no safety risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below by specific embodiment

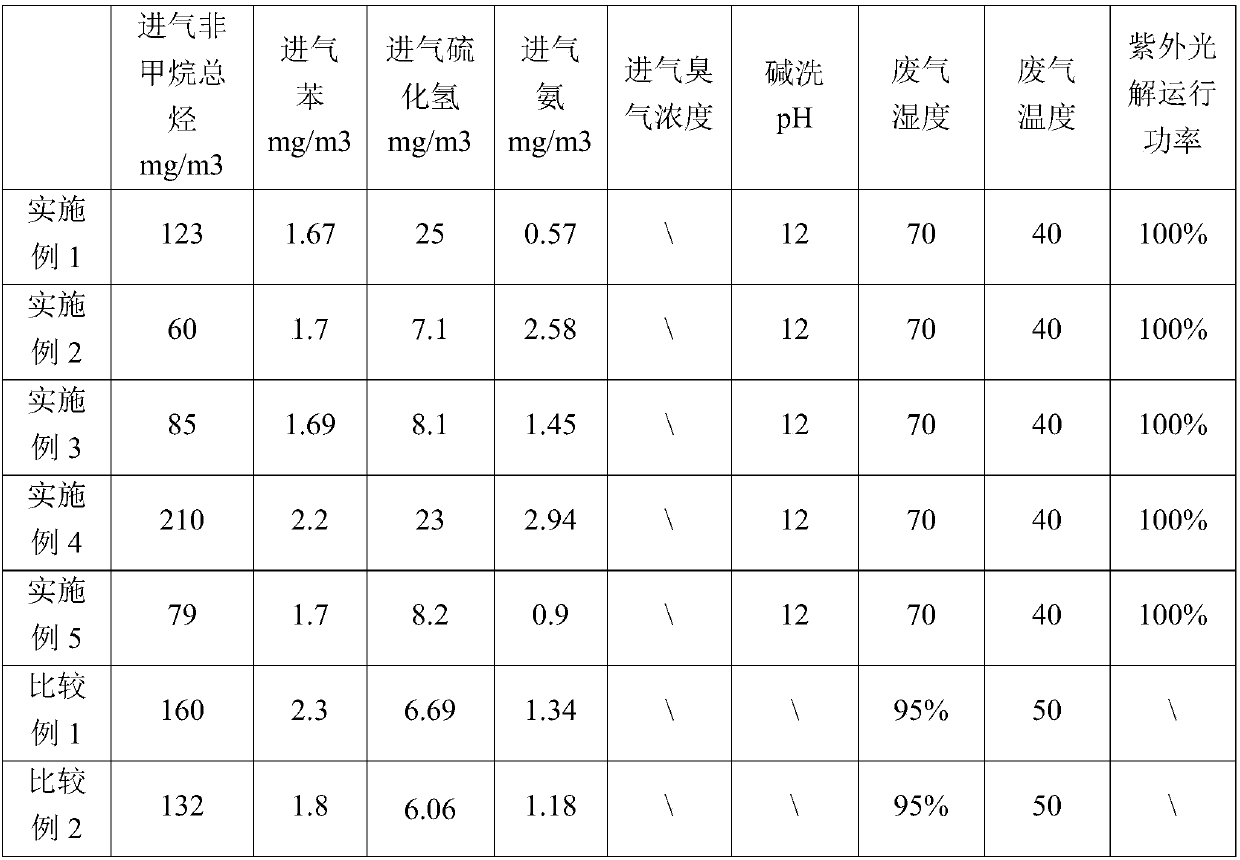

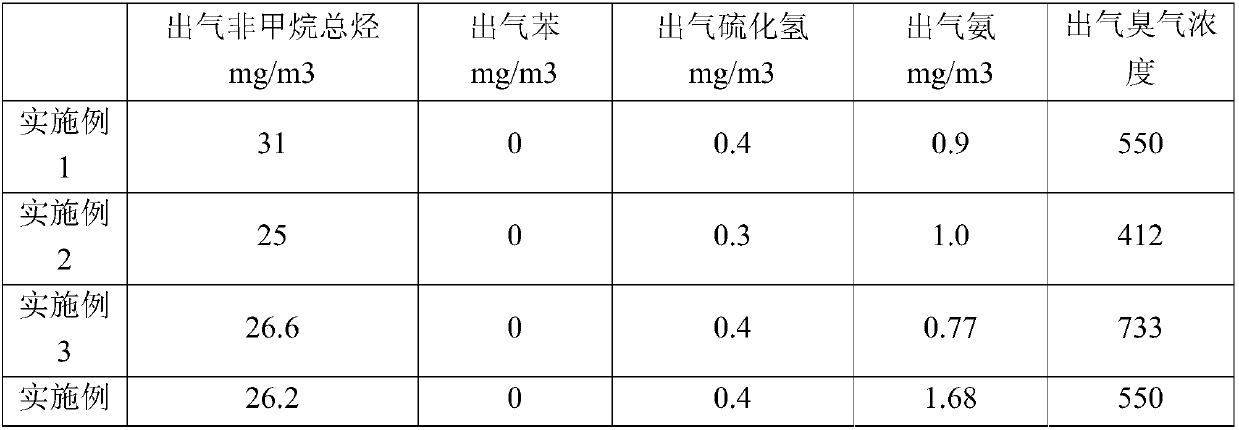

[0023] Exhaust gas in embodiment [1~5], comparative example [1~2] is the exhaust gas that the PTA sewage treatment plant of petrochemical enterprise produces, and intake air composition is:

[0024] Exhaust gas volume 20000m3 / h

[0025] Temperature 40~60℃

[0026] Humidity>95%

[0027] Total non-methane hydrocarbons 13~300mg / m3

[0028] Hydrogen sulfide 2~50mg / m3

[0029] Ammonia 0.5~2mg / m3

[0030] Benzene 3~30mg / m3

[0031] Odor concentration 4000~10000

[0032] Embodiment 【1~5】

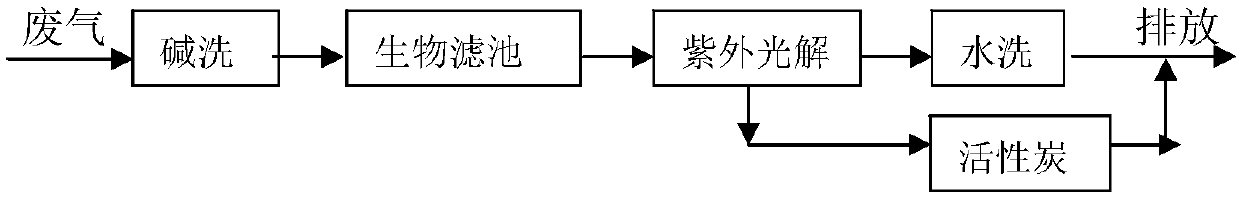

[0033] The waste gas produced by the PTA sewage field passes through the waste gas collection pipe and enters the alkali washing tower under the suction of the rear induced draft fan. The circulating spray pump is used for spraying alkali washing, and 30% liquid alkali is added to the sump of the alkali washing tower, and then The exhaust gas enters the biofilter and contacts with the microorganisms on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com