Method for increasing stability of Pickering emulsion based on modification with arginine

A technology of emulsion stability and arginine, which is applied to the preparation method of peptides, chemical instruments and methods, specific peptides, etc., can solve the problems of high requirements on ultrasonic power, temperature and processing time, and large energy consumption. To achieve the effect of enriching diversity, promoting development and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

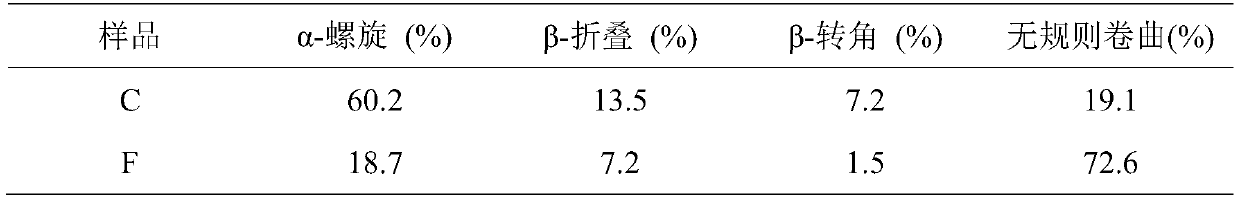

Image

Examples

Embodiment 1

[0033] A method for improving the stability of Pickering emulsion based on arginine modification, comprising the following steps:

[0034] (1) Preparation of myosin:

[0035] Reagent A: 0.1M potassium chloride, 20mM Tris, adjust pH to 7.5 with hydrochloric acid;

[0036] Reagent B: 0.45M potassium chloride, 0.2M magnesium acetate, 1mM EGTA, 20mM Tris, 5mM β-mercaptoethanol, adjust the pH to 6.8 with maleic acid;

[0037] Reagent C: 0.5M potassium chloride, 20mM Tris, 5mM β-mercaptoethanol, adjust the pH to 7.5 with hydrochloric acid;

[0038] Remove the head, viscera and skin of the fresh silver carp, take the back white meat, remove the bone, wash, cut into minced meat, add 10 times the volume of reagent A, and use a homogenizer to homogenize at 11000r / min for 3-5min. React at 4°C for 15 minutes, centrifuge (3000×g, 5min, 4°C), take the precipitate, add 5 times the volume of reagent B, add adenosine-5'-triphosphate disodium salt hydrate (ATP ), so that the final concentrat...

Embodiment 2

[0044] A method for improving the stability of Pickering emulsion based on arginine modification, comprising the following steps:

[0045] (1) Preparation of myosin:

[0046] Reagent A: 0.1M potassium chloride, 20mM Tris, adjust pH to 7.5 with hydrochloric acid;

[0047] Reagent B: 0.45M potassium chloride, 0.2M magnesium acetate, 1mM EGTA, 20mM Tris, 5mM β-mercaptoethanol, adjust the pH to 6.8 with maleic acid;

[0048] Reagent C: 0.5M potassium chloride, 20mM Tris, 5mM β-mercaptoethanol, adjust the pH to 7.5 with hydrochloric acid;

[0049] Remove the head, viscera and skin of the fresh silver carp, take the back white meat, remove the bone, wash, cut into minced meat, add 10 times the volume of reagent A, and homogenize with a homogenizer at 11000r / min for 3-5min. React at 4°C for 15 minutes, centrifuge (3000×g, 5min, 4°C), take the precipitate, add 5 times the volume of reagent B, add adenosine-5'-triphosphate disodium salt hydrate (ATP ), so that the final concentratio...

Embodiment 3

[0055] A method for improving the stability of Pickering emulsion based on arginine modification, comprising the following steps:

[0056] (1) Preparation of myosin:

[0057] Reagent A: 0.1M potassium chloride, 20mM Tris, adjust pH to 7.5 with hydrochloric acid;

[0058] Reagent B: 0.45M potassium chloride, 0.2M magnesium acetate, 1mM EGTA, 20mM Tris, 5mM β-mercaptoethanol, adjust the pH to 6.8 with maleic acid;

[0059] Reagent C: 0.5M potassium chloride, 20mM Tris, 5mM β-mercaptoethanol, adjust the pH to 7.5 with hydrochloric acid;

[0060] Remove the head, viscera and skin of the fresh silver carp, take the back white meat, remove the bone, wash, cut into minced meat, add 10 times the volume of reagent A, and homogenize with a homogenizer at 11000r / min for 3-5min. React at 4°C for 15 minutes, centrifuge (3000×g, 5min, 4°C), take the precipitate, add 5 times the volume of reagent B, add adenosine-5'-triphosphate disodium salt hydrate (ATP ), so that the final concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com