A ceramic ultrafiltration membrane with high-efficiency photocatalytic function and preparation method thereof

A ceramic ultrafiltration membrane and photocatalytic technology, applied in chemical instruments and methods, physical/chemical process catalysts, membranes, etc., can solve the problems of limited catalytic effect, poor penetration, easy absorption, etc., to improve the catalytic stroke and time, avoiding deactivation problems, and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

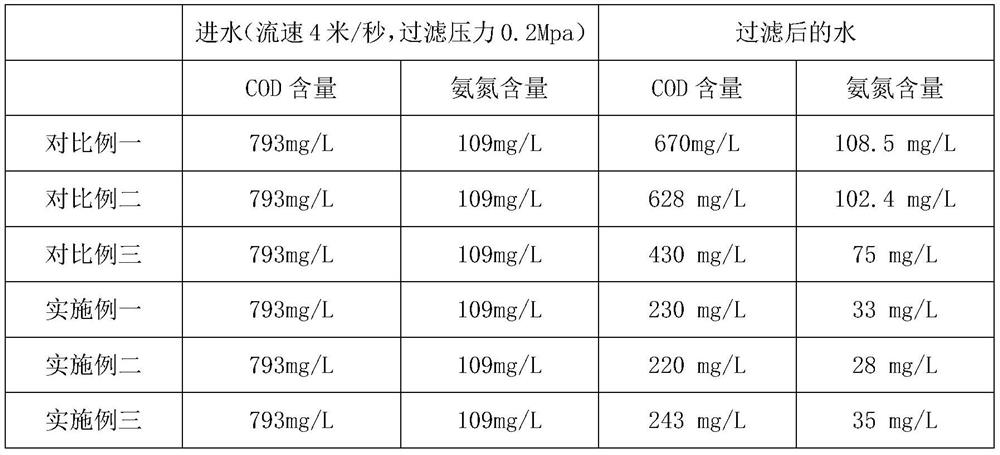

Examples

Embodiment 1

[0038] A method for preparing a ceramic ultrafiltration membrane with high-efficiency photocatalytic function, comprising the steps of:

[0039] The first step, according to the number of parts by mass, 100 parts of high-purity quartz powder with a particle size of 20um and a purity higher than 99.5%, 15 parts of high-purity quartz powder with a particle size of 0.3um and a purity higher than 99.5%, 5 parts The binder, 2 parts of lubricant and 20 parts of water are stirred evenly together, extruded or molded into a tubular or flat green body and dried.

[0040] The second step is to put the dried green body into a kiln and sinter it into a high-purity quartz porous support with a certain strength. The sintering temperature is 1600°C and the sintering time is 50 hours.

[0041] The third step is to uniformly mix 15 parts of high-purity quartz powder with a particle size of 0.1um and a purity higher than 99.5%, 2 parts of binder, 3 parts of film-forming agent, and 100 parts of w...

Embodiment 2

[0049] A method for preparing a ceramic ultrafiltration membrane with high-efficiency photocatalytic function, comprising the steps of:

[0050] The first step, according to the number of parts by mass, 100 parts of high-purity alumina powder with a particle size of 50um and a purity higher than 99.9%, 30 parts of high-purity alumina powder with a particle size of 1.5um and a purity higher than 99.5%, 6 parts of binder, 3 parts of lubricant and 20 parts of water are stirred evenly together, extruded or molded into a tubular or flat green body and dried.

[0051] The second step is to put the dried green body into a kiln and sinter it into a high-purity quartz porous support with a certain strength. The sintering temperature is 1600°C and the sintering time is 80h.

[0052] The third step is to uniformly mix 10 parts of high-purity alumina powder with a particle size of 0.5um and a purity higher than 99.5%, 3 parts of binder, 3 parts of film-forming agent, and 100 parts of wate...

Embodiment 3

[0060] A method for preparing a ceramic ultrafiltration membrane with high-efficiency photocatalytic function, comprising the steps of:

[0061] The first step, according to the number of parts by mass, 100 parts of high-purity quartz powder with a particle size of 100um and a purity higher than 99.5%, 20 parts of high-purity quartz powder with a particle size of 3um and a purity higher than 99.5%, 8 parts of viscose The binder, 2 parts of lubricant and 22 parts of water are stirred evenly together, extruded or molded into a tubular or flat green body and dried.

[0062] The second step is to put the dried green body into a kiln and sinter it into a high-purity quartz porous support with a certain strength. The sintering temperature is 1750°C and the sintering time is 55 hours.

[0063] In the third step, 12 parts of high-purity quartz powder with a particle size of 1 um and a purity higher than 99.5%, 2 parts of a binder, 4 parts of a film-forming agent, and 100 parts of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com