Method for extracting tryptophan from fermentation broth

A fermentation broth, tryptophan technology, applied in the direction of organic chemistry, can solve the problems of increasing the burden of subsequent processes, increasing the volume of materials, increasing production costs, etc., to reduce the consumption of water resources and heat energy, improve product yield, save Effects of water and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

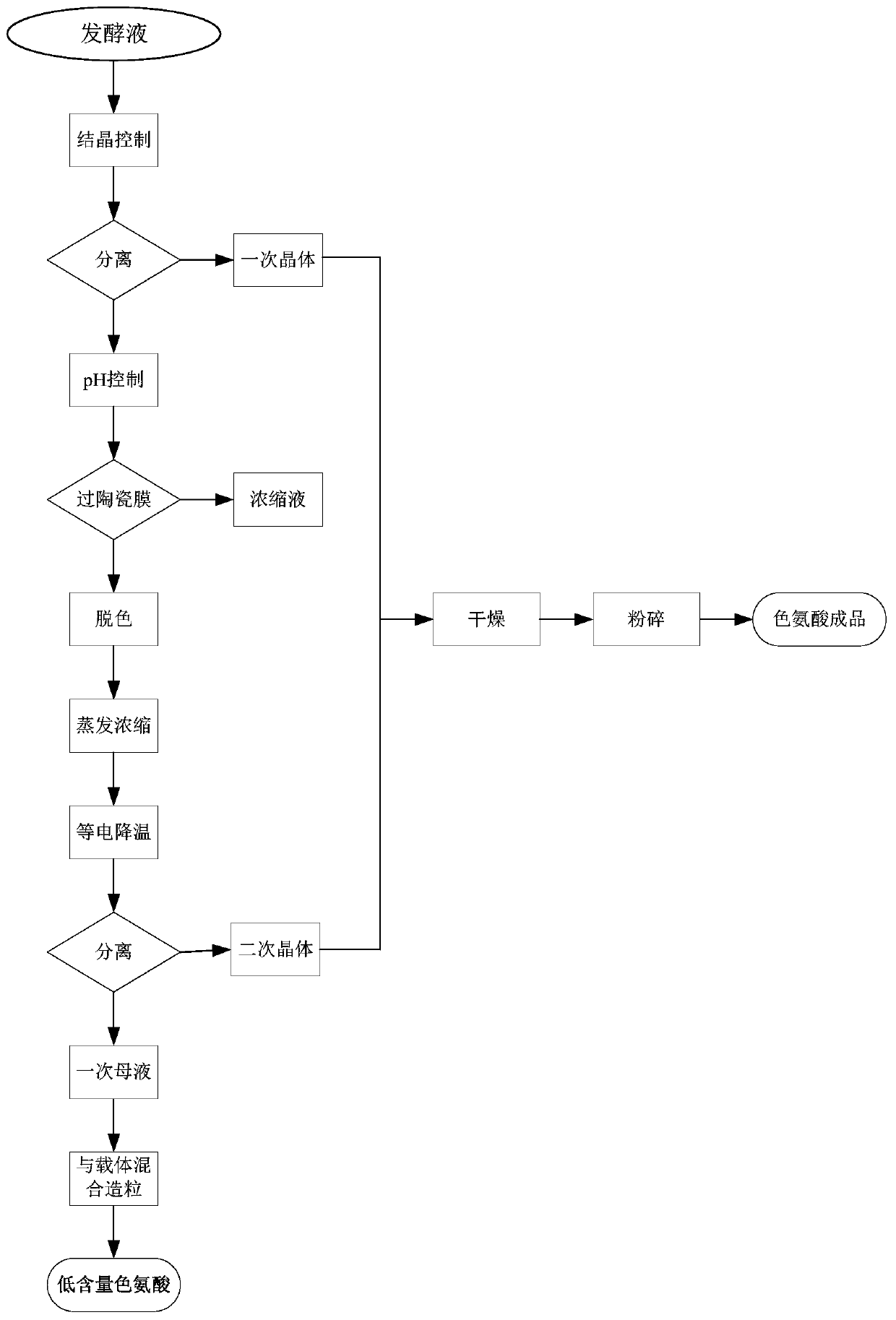

Method used

Image

Examples

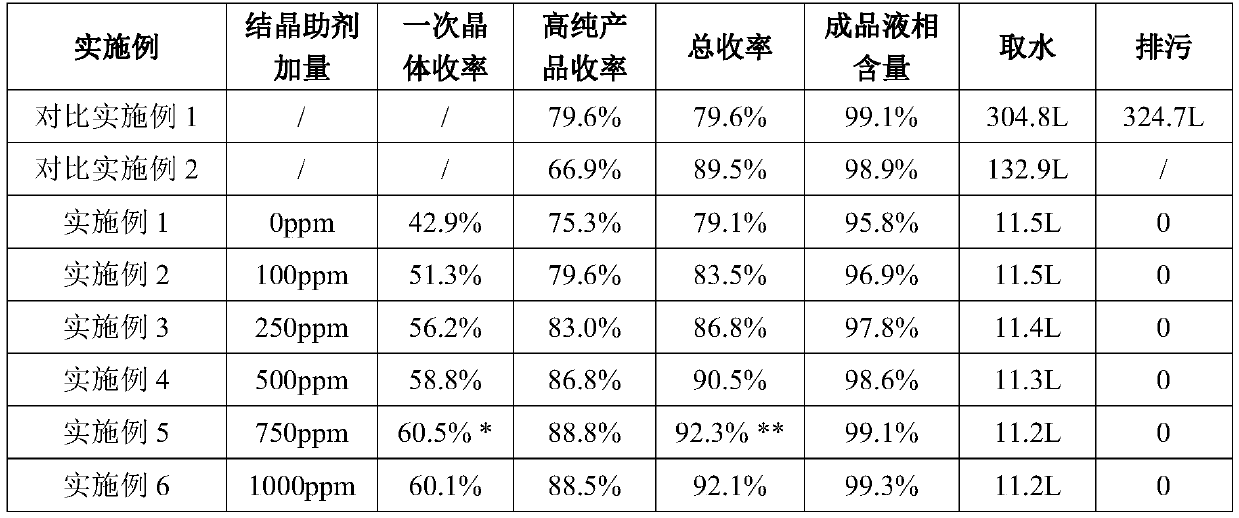

Embodiment 1

[0041] Example 1: A method for extracting tryptophan from fermentation broth, this example does not add a crystallization aid, the specific steps are:

[0042] After the fermentation is over, immediately take 30L of fermentation broth, the content of L-tryptophan in the fermentation broth is 51.6g / L, control the stirring speed to 100 rpm, adjust the pH value of the fermentation broth for isoelectric crystallization, specifically: Sulfuric acid is added to the fermentation broth to adjust the pH of the fermentation broth to 5.90±0.02 at a rate of 0.1 per 5 minutes. After the pH is reached, the pH is maintained for 15 minutes. The isoelectric crystallization temperature is 40℃; after the isoelectric crystallization, the temperature drops and the temperature gradient is lowered. In order to reduce the temperature by 3°C per hour, the temperature is lowered to 10°C and maintained for 30 minutes. Use an automatic slag filter to filter and separate the crystals. Add 6L of ethanol with ...

Embodiment 2

[0049] Embodiment 2: A method for extracting tryptophan from fermentation broth. In this embodiment, 100 ppm of crystallization aid is added. The specific steps are:

[0050] After the fermentation is over, immediately take 30L of fermentation broth, the content of L-tryptophan in the fermentation broth is 50.4g / L, control the stirring speed to 100 rpm, add 100ppm fatty acid glycerides, adjust the pH value of the fermentation broth for isoelectric Crystallization is specifically: adding sulfuric acid to the fermentation broth to adjust the pH of the fermentation broth to 5.90±0.02 at a rate of 0.1 per 5 minutes. After the pH is reached, it is maintained for 15 minutes, and the isoelectric crystallization temperature is 40°C; after isoelectric crystallization Begin cooling crystallization, the cooling gradient is 3℃ per hour, and the temperature is reduced to 10℃ and maintained for 30 minutes. Use an automatic slag filter to filter and separate the crystals. Add 6L of ethanol with...

Embodiment 3

[0057] Embodiment 3: A method for extracting tryptophan from fermentation broth. In this embodiment, 250 ppm of crystallization aid is added, and the specific steps are:

[0058] After the fermentation is over, immediately take 30L of fermentation broth, the content of L-tryptophan in the fermentation broth is 52.6g / L, control the stirring speed to 200 rpm, add 250ppm fatty acid glycerides, adjust the pH value of the fermentation broth for isoelectric Crystallization is specifically: adding sulfuric acid to the fermentation broth to adjust the pH of the fermentation broth to 5.90±0.02 at a rate of 0.1 per 5 minutes. After the pH is reached, it is maintained for 15 minutes, and the isoelectric crystallization temperature is 38°C; after isoelectric crystallization Begin cooling and crystallization, and the cooling gradient is 3°C per hour until the temperature is 15°C and maintained for 30 minutes. Use an automatic slag filter to filter and separate the crystals, add 6L of ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com