A kind of preparation method of polyurethane prepolymer

A technology of polyurethane prepolymer and polyurethane, applied in the direction of polyurea/polyurethane adhesive, sustainable manufacturing/processing, non-polymer adhesive additives, etc., can solve the problem of unstable polyurethane prepolymer and low production efficiency , prepolymer yellowing and other problems, to achieve the effect of improving compatibility and heating/radiation uniformity, low fog value, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

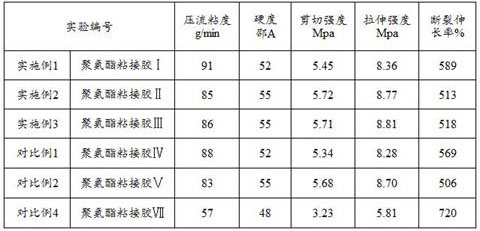

Examples

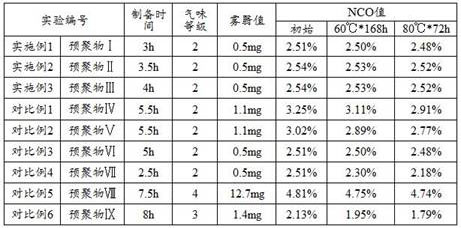

Embodiment 1

[0034] Prepolymer I.: In a dried three-mouth flask, 24.5 parts of polyetherdiol Tdiol-2000 (molecular weight 2000), 40.2 parts of polyether ternitol F3128 (molecular weight 6000), 11.144 parts diisooctyl phthalate, 0.01 parts of toluene sulfonyl isocyanate, stirred at 50 °C ~ 55 °C vacuum mixed for 20min, wherein the vacuum degree ≤-0.09MPa. Nitrogen pressure relief, wherein the nitrogen purity ≥ 95%, the 13 parts diphenylmethane-4,4'-diisocyanate and 0.002 parts dibutyltin dilaurate were added to the step reaction mixture, the feeding control was controlled within 5 minutes, vacuum stirring heating, wherein the heating rate was 10 °C / 10min, the vacuum degree ≤-0.09MPa, at a temperature of 65 °C ± 2 °C, after the reaction of 1.5 hours, the NCO reached the preset target ≤2.95%, turn off the heating and heat preservation equipment. Nitrogen pressure relief, wherein the nitrogen purity ≥ 95%, the room temperature conditions of 11.144 parts of diisooctyl phthalate added to the reacti...

Embodiment 2

[0037]Prepolymer II., in a dry three-mouth flask added 22 parts of polyether diol Tdiol-3000 (molecular weight 3000), 48.5 parts of polyether ternary alcohol GEP-330N (molecular weight 5000), 5.5 parts diisooctyl phthalate, 0.01 parts of toluene sulfonyl isocyanate, stirred at 50 °C ~ 55 °C vacuum mixed for 20min, wherein the vacuum degree ≤-0.09MPa. Nitrogen pressure relief, wherein the nitrogen purity ≥ 95%, the 13 parts diphenylmethane-4,4'-diisocyanate and 0.002 parts dibutyltin dilaurate were added to the reaction mixture, the feeding was controlled within 5 minutes, vacuum stirring heating, wherein the heating rate was 10 °C / 10min, the vacuum degree was ≤ -0.09MPa, at a temperature of 65 °C ± 2 °C, the reaction was 1.5 hours, the NCO reached the preset target ≤ 2.85%, and the heating and heat preservation equipment was turned off. Nitrogen pressure relief, of which nitrogen purity ≥ 95%, the room temperature conditions of 11 parts of diisooctyl phthalate added to the reactio...

Embodiment 3

[0040]Prepolymer III.: In a dried three-mouth flask, 26.7 parts of polyetherdiol Tdiol-2000 (molecular weight 2000), 42.8 parts of polyether tereth terethyl alcohol F3135 (molecular weight 5000), 5 parts of diisooctyl phthalate and dioctyl terephthalate (V: V = 1: 1) mixture, 0.03 parts of toluene sulfonyl isocyanate, stirred at 50 ° C ~ 55 ° C vacuum mixed for 20min, wherein the vacuum degree ≤-0.09MPa. Nitrogen pressure relief, wherein the nitrogen purity ≥ 95%, the 10.467 parts of hexamethylene diisocyanate, 0.003 parts of dibutyltin diacetate were added to the step reaction mixture, the addition control was controlled within 5 minutes, vacuum stirring heating, wherein the heating rate was 10 °C / 10min, the vacuum degree ≤ -0.09MPa, at a temperature of 65 °C ± 2 °C, after the reaction of 1.5 hours, NCO reached the preset target of 3.56% ≤, turn off the heating and insulation equipment. Nitrogen pressure relief, wherein the nitrogen purity ≥ 95%, the room temperature under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com