Current ripple compensation circuit and method adopting wide bandgap device and silicon-based device

A technology of current ripple and compensation circuit, applied in the field of power electronics, can solve the problems of large switching loss and high price of wide bandgap devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

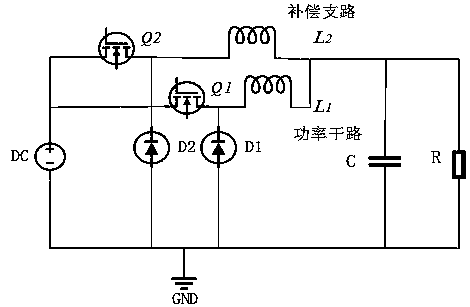

[0067] Such as Figure 1 As shown, the working circuit of a non-isolated ripple-compensated Buck power converter provided in this embodiment includes a parallel power main circuit and a compensation branch, and the DCDC output terminal is connected to a parallel capacitor C through the power main circuit and the compensation branch. Connect to resistor R and connect to ground through capacitor C and resistor R. The main power circuit includes the switch tube IGBT Q in series 1 and power inductor L 1 , switching tube IGBT Q 1 and power inductor L 1 common terminal through the first diode D 1 grounded. The compensation branch includes a series switch GaN device Q 2 and compensation inductance L 2 , switch tube GaN device Q 2 and compensation inductance L 2 common terminal through the second diode D 2 grounded. The power main circuit controls the large current, and the compensation branch is used to compensate the current ripple brought by the power main circuit.

Embodiment 2

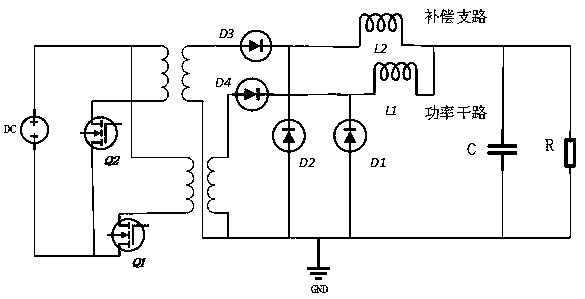

[0069] Such as figure 2 As shown, the working circuit of an isolated forward converter with isolated ripple compensation provided in this embodiment includes a parallel power main circuit and a compensation branch circuit, and the power main circuit includes a switching tube IGBT Q 1 , the fourth diode D 4 and the first diode D 1 , switching tube IGBT Q 1 It is connected in parallel with the power supply DC, and the switching tube IGBT Q 1 with the fourth diode D 4 are isolated by a transformer, the fourth diode D 4 Respectively with the power inductor L 1 and the first diode D 1 connect. The compensation branch includes the switching tube GaN device Q 2 , the third diode D 3 and the second diode D 2 , switch tube GaN device Q 2 It is connected in parallel with the power supply DC, and the switching tube GaN device Q 2 with the third diode D 3 are isolated by a transformer, the third diode D 3 respectively with compensation inductance L 2 and the second diode D...

Embodiment 1

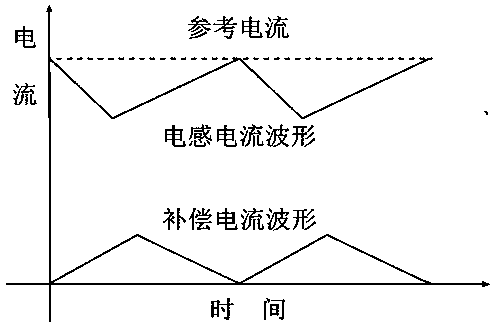

[0071] In Embodiment 1 and Embodiment 2, the main power circuit operates at a low frequency state, flows a large current, and is the main power output circuit. The compensation branch controls the inductance L through the hysteresis 2 The output current is used to track the deviation current between the current reference value and the power main circuit inductor current value, which is used to compensate the current ripple. Finally, the superposition of the two branch currents is equal to the given reference current value, such as image 3 shown. As a result, the output current ripple is greatly reduced, thereby reducing the output voltage ripple.

[0072] A DCDC current ripple active compensation method includes a parallel power main circuit and a compensation branch circuit. The power main circuit operates in a low-frequency state and flows through a large current, and is a main power output circuit. The compensation branch uses hysteresis control to compensate the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com