Preparation method of carbonyl powder

A technology of carbonyl powder and carbonyl iron powder, applied in the field of carbonyl powder preparation, can solve the problems of complex method, unsuitability for mass production, increased corrosion resistance and high temperature resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

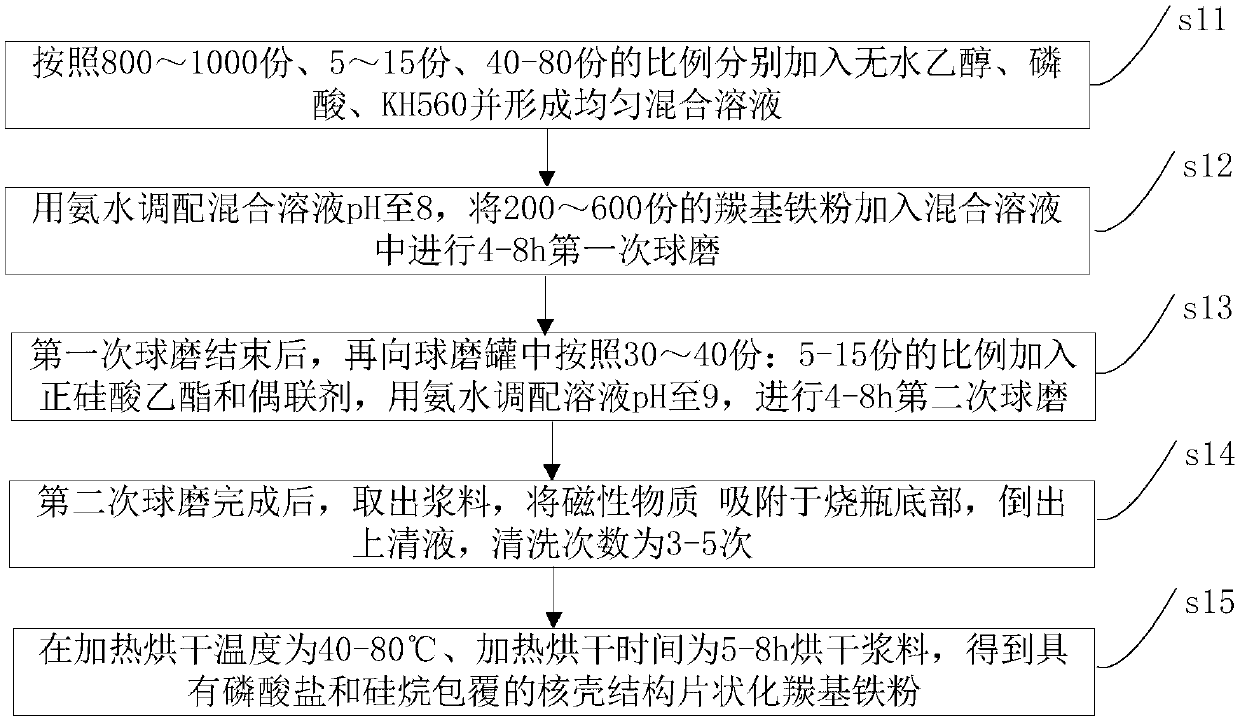

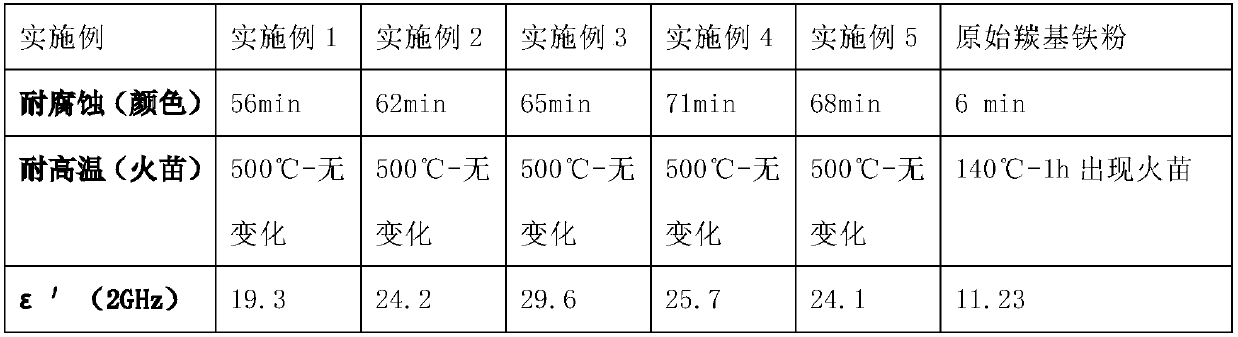

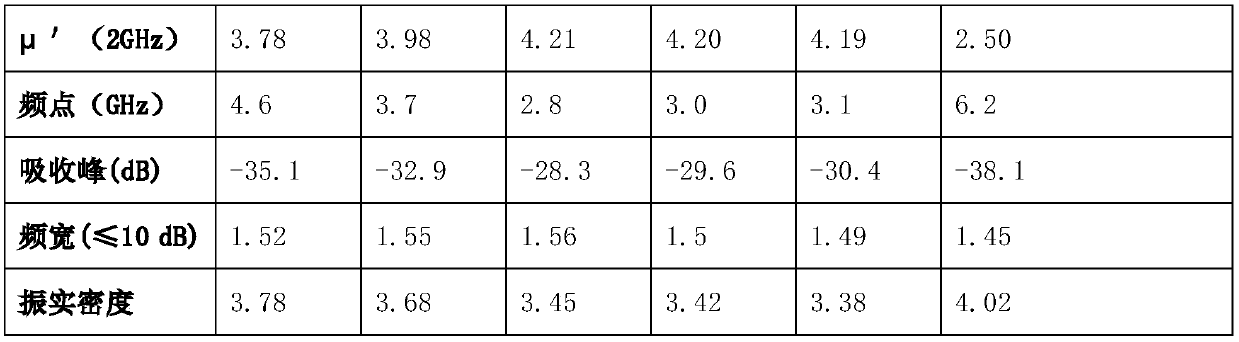

[0019] Such as figure 1 An embodiment of the present invention provides a carbonyl powder preparation method, including: adding absolute ethanol, phosphoric acid, and KH560 in proportions of 800-1000 parts, 5-15 parts, and 40-80 parts respectively to form a uniform mixed solution; Prepare the pH of the mixed solution with ammonia water to 8, add 200-600 parts of carbonyl iron powder into the mixed solution for the first ball milling for 4-8 hours; - Add tetraethyl orthosilicate and coupling agent at a ratio of 15 parts, adjust the pH of the solution to 9 with ammonia water, and perform the second ball milling for 4-8 hours; after the second ball milling is completed, take out the slurry and adsorb magnetic substances such as magnets At the bottom of the flask, pour out the supernatant, and wash for 3-5 times; dry the slurry at a heating and drying temperature of 40-80°C and a heating and drying time of 5-8 hours to obtain a phosphate- and silane-coated Core-shell structure fl...

Embodiment 1

[0022] (1) Heat the carbonyl iron powder at 80°C for 30 minutes in a vacuum state to eliminate internal stress, and keep it for later use. Add anhydrous ethanol, phosphoric acid, and KH560 to the horizontal planetary ball mill tank in sequence according to 800 parts, 5 parts, and 40 parts respectively to form a uniform mixed solution. Use ammonia water to adjust the pH of the solution to 8, and add 200 parts of carbonyl iron powder to the mixture. Carry out ball milling in the good solution, set ball mill rotating speed 300r / min, ball milling time is 4. Among them, the ball material ratio of agate beads and carbonyl iron powder is 5:1, and the agate beads are composed of three kinds of large, medium and small agate beads with diameters of 10mm, 6mm and 3mm, and the mass ratio of the large, medium and small three kinds of agate beads is 2 :25:50, the total weight of the three is 2.5Kg.

[0023] (2) After the ball milling time is over, add tetraethyl orthosilicate and a couplin...

Embodiment 2

[0025] (1) Heat the carbonyl iron powder at 80°C for 30 minutes in a vacuum state to eliminate internal stress, and keep it for later use. Add anhydrous ethanol, phosphoric acid, and KH560 to the horizontal planetary ball mill tank in sequence according to 900 parts, 10 parts, and 60 parts respectively to form a uniform mixed solution, adjust the pH of the solution to 8 with ammonia water, and add 400 parts of carbonyl iron powder Carry out ball milling in the prepared solution, set the rotating speed of the ball mill to 400r / min, and the ball milling time to 6. Among them, the ball material ratio of agate beads and carbonyl iron powder is 6:1, and the agate beads are composed of three kinds of large, medium and small agate beads with diameters of 10mm, 6mm and 3mm, and the mass ratio of the large, medium and small three kinds of agate beads is 2 :25:50, the total weight of the three is 2.5Kg.

[0026] (2) After the ball milling time is over, add tetraethyl orthosilicate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com