Polycarboxylate superplasticizer containing phosphate group as well as preparation method and application of polycarboxylate superplasticizer

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of low conversion rate of phosphoric acid monomer, restricting industrial production, harsh conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

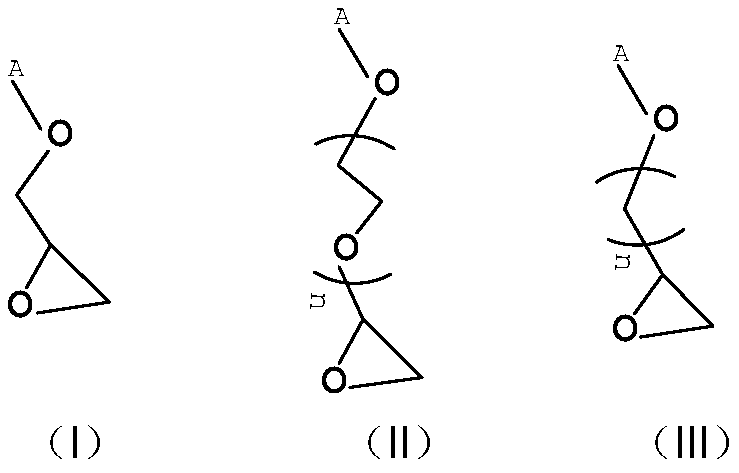

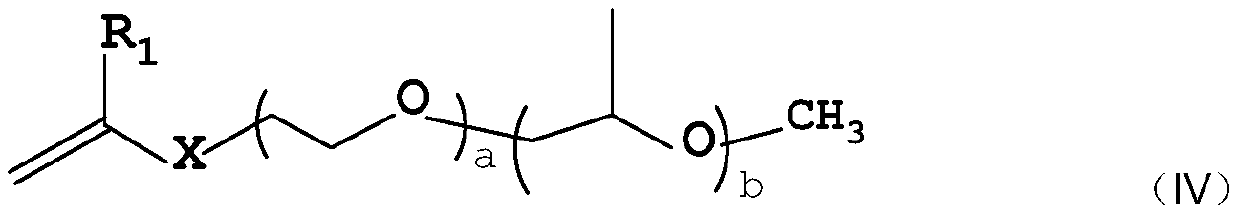

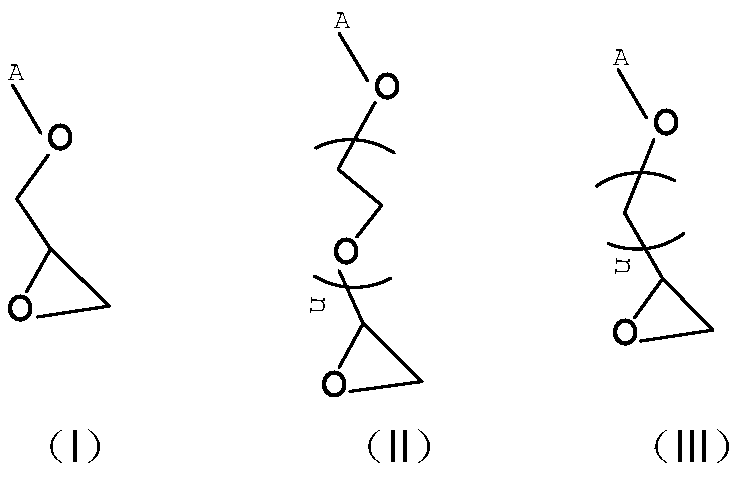

Method used

Image

Examples

Embodiment 1

[0041] Preparation of ethylene oxide polyether:

[0042] The initiator is allyl alcohol, and the catalyst is sodium methoxide. Weigh 58g (1mol) of allyl alcohol and 3g of sodium methoxide, put the above materials into the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature of the reaction kettle was raised to 100° C., and 50 g of ethylene oxide was introduced into the reaction kettle. When the pressure in the reaction kettle dropped and the temperature rose, it indicated that the polymerization reaction started. Continue to feed 1892g of ethylene oxide into the reactor. During the feeding process, keep the temperature of the reactor between 100-120°C and the pressure between 0.2-0.4MPa. After the addition of ethylene oxide is completed, keep the temperature at 100°C for about 1h . When the pressure of the reactor no longer drops, reduce the temperature of the reactor to about 80°C, open the vent valve to reduce the pressure in the reactor ...

Embodiment 2

[0050] Preparation of ethylene oxide, propylene oxide block polyether:

[0051] Starter 3-methyl-3-buten-1-ol, catalyst sodium hydride (60%). Weigh 48 g (0.5 mol) of 3-methyl-3-buten-1-ol and 2 g of sodium hydride, put the above materials into the reactor, and evacuate the reactor to -0.1 MPa at room temperature. Then the temperature of the reaction kettle is raised to 100°C, and 40g of propylene oxide is passed into the reaction kettle. When the pressure in the reaction kettle drops and the temperature rises, it means that the polymerization reaction starts. Go down again. Then continuously feed 1662g of ethylene oxide into the reaction kettle, keep the temperature of the reaction kettle between 100-120°C and the pressure between 0.2-0.4MPa during the feeding process, and keep the temperature at 100°C for 1h after the addition of ethylene oxide is completed about. When the pressure of the reactor no longer decreases, reduce the temperature of the reactor to about 80°C, ope...

Embodiment 3

[0056] For phosphorylation reagents containing phosphorous acid groups, we use the Mannich reaction in organic chemistry to realize the Mannich reaction of ethylenediamine as an example: take 1.5g (0.025mol) of ethylenediamine and put it in 50ml In the there-necked flask, add 6.2 g of phosphorous acid (0.075 mol), 5.2 g (0.05 mol) of hydrochloric acid with a mass fraction of 35%, add dropwise 7.3 g (0.09 mol) of 37% formaldehyde solution, and heat to reflux at 100°C for 24 hours. After the reaction was completed, it was cooled to room temperature, and a sample was tested by liquid chromatography, and the conversion rate of ethylenediamine was close to 100%. Afterwards, 32% NaOH solution was added to the reaction system to adjust the pH to 8-9, and a tan liquid was finally obtained, which was designated as P1. Since the polyamine substrate is basically completely converted, the moles of the subsequent phosphorylation reagents containing phosphorous acid groups are calculated ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com