A kind of high-strength and high flame-retardant organosilicon foam material and its preparation method

A technology of organosilicon foam and high flame retardancy, which is applied in the field of high strength and high flame retardancy organosilicon foam material and its preparation, which can solve the problems of poor mechanical properties and poor flame retardancy, so as to improve flame retardancy and slow down volatilization and diffusion, the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

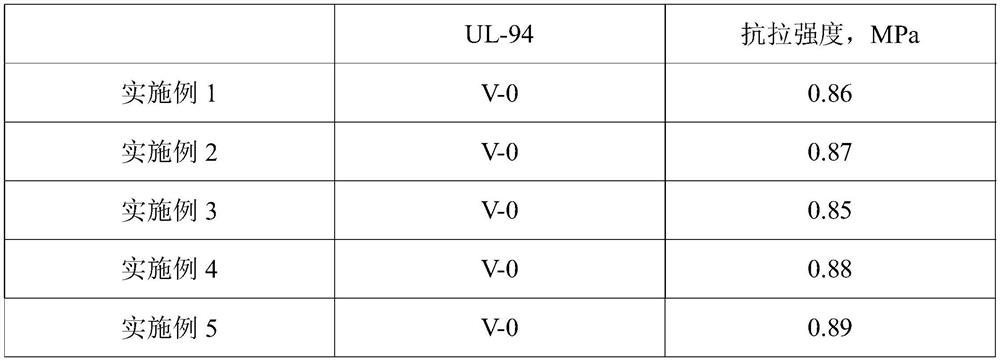

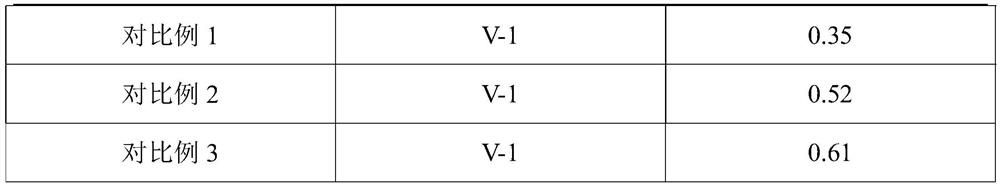

Examples

Embodiment 1

[0034] A high-strength and highly flame-retardant silicone foam material, comprising component A and component B at a weight ratio of 1:1, wherein component A includes the following components in parts by weight:

[0035] 18 parts of hydroxyl silicone oil, 20 parts of vinyl silicone oil, 29 parts of flame retardant filler, 6 parts of fumed silica, 16 parts of hollow glass microspheres, 10 parts of nano calcium carbonate, 1 part of platinum catalyst;

[0036] Component B is in parts by weight and includes the following components:

[0037] 30 parts of hydroxyl silicone oil, 36 parts of vinyl silicone oil, 10 parts of flame retardant filler, 6 parts of fumed silica, 8 parts of hollow glass microspheres, 5 parts of nano-calcium carbonate, 1 part of carbon black, 1 part of acetylenic alcohol, hydrogen-containing silicone oil 4 parts;

[0038] The flame retardant filler is a mixture of molybdenum disulfide / zinc ferrite hybrid cyclic polyphosphazene composite material, aluminum hyd...

Embodiment 2

[0047] A high-strength and highly flame-retardant silicone foam material, comprising component A and component B at a weight ratio of 1:1, wherein component A includes the following components in parts by weight:

[0048] 18 parts of hydroxyl silicone oil, 20 parts of vinyl silicone oil, 29 parts of flame retardant filler, 6 parts of fumed silica, 16 parts of hollow glass microspheres, 10 parts of nano calcium carbonate, 1 part of platinum catalyst;

[0049] Component B is in parts by weight and includes the following components:

[0050] 30 parts of hydroxyl silicone oil, 36 parts of vinyl silicone oil, 10 parts of flame retardant filler, 6 parts of fumed silica, 8 parts of hollow glass microspheres, 5 parts of nano-calcium carbonate, 1 part of carbon black, 1 part of acetylenic alcohol, hydrogen-containing silicone oil 4 parts;

[0051] The flame retardant filler is a mixture of molybdenum disulfide / zinc ferrite hybrid cyclic polyphosphazene composite material, aluminum hyd...

Embodiment 3

[0060] A high-strength and highly flame-retardant silicone foam material, comprising component A and component B at a weight ratio of 1:1, wherein component A includes the following components in parts by weight:

[0061] 19 parts of hydroxyl silicone oil, 25 parts of vinyl silicone oil, 30 parts of flame retardant filler, 7 parts of fumed silica, 15 parts of hollow glass microspheres, 9 parts of nano-calcium carbonate, 2 parts of platinum catalyst;

[0062] Component B is in parts by weight and includes the following components:

[0063] 32 parts of hydroxyl silicone oil, 35 parts of vinyl silicone oil, 12 parts of flame retardant filler, 7 parts of fumed silica, 10 parts of hollow glass microspheres, 6 parts of nano-calcium carbonate, 1 part of carbon black, 1 part of acetylenic alcohol, hydrogen-containing silicone oil 5 copies;

[0064] The flame retardant filler is a mixture of molybdenum disulfide / zinc ferrite hybrid cyclic polyphosphazene composite material, aluminum h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com