P-N heterojunction composite material loaded on surface of foamed nickel and preparation method and application thereof

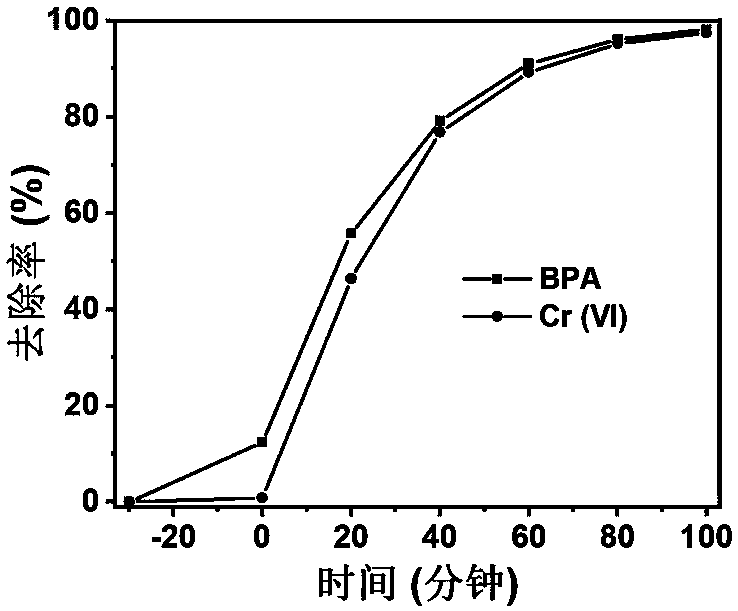

A technology of composite materials and nickel foam, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve problems such as insufficient catalytic efficiency, achieve simple and fast reuse, and expand light Response area, the effect of simple and easy-to-obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of layered nickel-iron double metal hydroxide precursor solution, concrete steps are as follows:

[0030] First, 15 ml of deionized water, 0.6979 g of nickel nitrate hexahydrate and 0.4803 g of ferric nitrate nonahydrate were successively added to a single-necked round bottom flask, and after stirring evenly, 0.8647 g of urea was added, and after stirring evenly, reflux at 100 °C for 24 h, namely Obtain the precursor solution of layered nickel-iron double metal hydroxide, in which the divalent metal ion Ni 2+ with trivalent metal ion Fe 3+ The molar ratio of Fe is 2:1, Fe 3+ The molar concentration of urea is 0.1 mol / L, and the molar number of urea is divalent metal ion Ni 2+ with trivalent metal ion Fe 3+ 4 times the sum of moles.

Embodiment 2

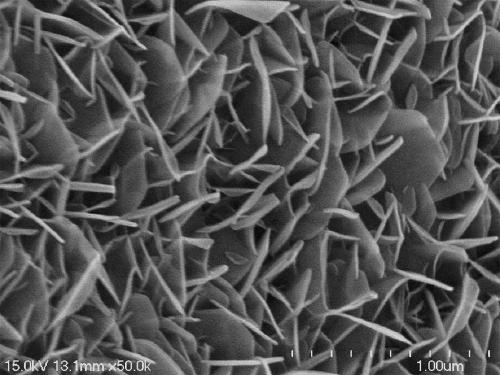

[0032] The layered nickel-iron double hydroxide nanosheet composite (Ni foam@NiFe-LDH) loaded on the surface of nickel foam was prepared by hydrothermal method, and the specific steps were as follows:

[0033] The invention adopts a hydrothermal method to synthesize the layered nickel-iron double hydroxide nanosheet composite material (Ni foam@NiFe-LDH) loaded on the surface of nickel foam. The nickel foam was put into a polytetrafluoroethylene-lined autoclave, and 3 ml of the layered nickel-iron double metal hydroxide precursor solution prepared in Example 1 and 32 ml of deionized water were added. The reactor was placed in an oven with a preset temperature, and subjected to constant temperature hydrothermal reaction at 160 °C for 24 h. After the reaction, the heating was stopped. After the reaction kettle was naturally cooled to room temperature, the product was centrifuged and washed three times with deionized water, and dried in a blast oven at 60 °C for 24 h to obtain lay...

Embodiment 3

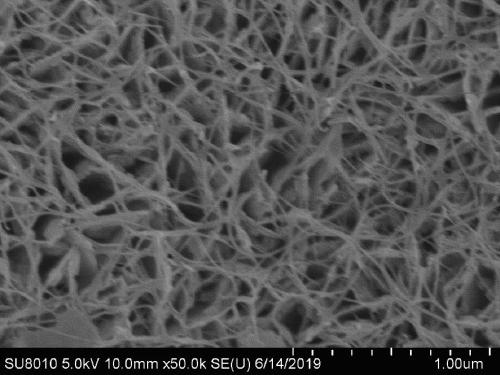

[0035] P-N heterojunction composites supported on nickel foam surface prepared by mixed solvothermal method (Ni foam@NiFe-LDH / Co 3 o 4 -1) Catalyst, the specific steps are as follows:

[0036] The present invention uses a mixed solvothermal method to synthesize the above-mentioned P-N heterojunction catalyst composite material (Ni foam@NiFe-LDH / Co 3 o 4 -1). First, 40 ml of deionized water, 40 ml of absolute ethanol, 0.87 g of cobalt nitrate hexahydrate and 0.7206 g of urea were sequentially added into a beaker, and ultrasonically dispersed to obtain a uniform mixed solution. Put the layered nickel-iron double hydroxide nanosheet composite (Ni foam@NiFe-LDH) obtained in Example 2 loaded on the surface of nickel foam into a polytetrafluoroethylene-lined autoclave, and add 10 ml of the above mixed solution and 25 ml of a mixed solution of deionized water and absolute ethanol (volume ratio of 1:1). The reaction kettle was placed in an oven with a preset temperature, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com