Novel high-strength aluminum alloy particle reinforced aluminum matrix composite material and preparation method thereof

An aluminum-based composite material and particle strengthening technology, which is applied in the field of composite material preparation, can solve problems such as difficulty in adding high-content ceramic particles, abnormal diffusion of element segregation, and reduced particle strengthening efficiency, so as to improve interface bonding ability and easily obtain , high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

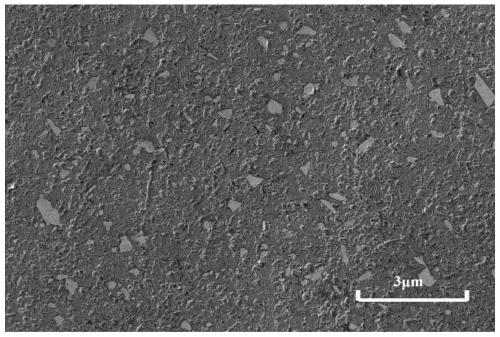

Embodiment 1

[0054] The 2050 aluminum alloy particles with Al-Cu-Li (3.4wt.%, 1.2wt.% Li, Al-bal) as the main component are the reinforcing particles, and the proportion is 10vol.% of the reinforcing particles in volume percentage, and the rest is Al .

[0055] The specific microwave sintering preparation method of the particle reinforced aluminum matrix composite material of the present invention is:

[0056] (1) ball mill

[0057] Step-by-step ball milling, first ball mill Al-Cu-Li 2050 aluminum alloy particles separately, the ball-to-material ratio is 15:1; high-speed ball milling, the speed is 250r / min; the ball milling time is 10h, and the high ball-to-material ratio of 10:1 is used for Al particle ball milling; Medium-speed ball milling, the rotating speed is 200r / min; the ball milling time is 22h. Then add ethanol according to the proportion of the formula, the ratio of ball to material is 2:1, and the rotation speed is 150r / min, and the mixed powder is wet milled in a planetary b...

Embodiment 2

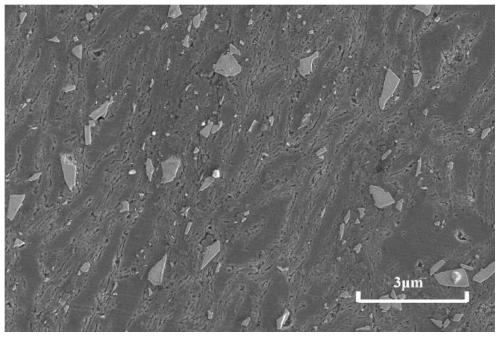

[0065] 2A04 hard aluminum alloy with Al-Cu-Mn-Mg (3.6wt.% Cu, 0.7wt.% Mn, 2.5wt.% Mg, Al-bal) as the main component is used as the external strengthening phase, and the proportion is calculated by volume percentage 25vol.% for reinforcing particles, the rest is Al.

[0066] The specific microwave sintering preparation method of the particle reinforced aluminum matrix composite material of the present invention is:

[0067] (1) ball mill

[0068] Step-by-step ball milling, first ball mill the 2189 aluminum alloy particles separately, the ball-to-material ratio is 10:1; high-speed ball milling, the speed is 300r / min; the ball milling time is 12h, and the high-ball-to-material ratio is 15:1 for Al particle ball milling; medium-speed ball milling, The rotating speed is 150r / min; the ball milling time is 24h. Then mix according to the formula ratio, add ethanol, the ball-to-material ratio is 2:1, and wet-mill and mix the powder in a planetary ball mill for 5 hours at a speed of 1...

Embodiment 3

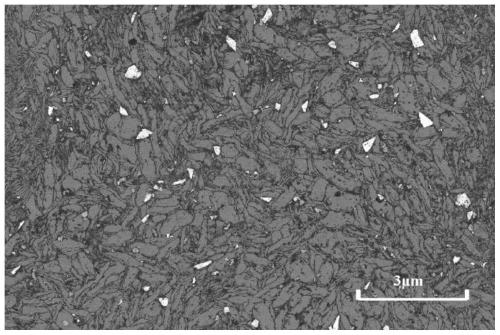

[0076] Al-Zn-Mg-Cu (5.6wt.% Zn, 2.8wt.% Mg, 1.8wt.% Cu, Al-bal) 7055 alloy particles are used as the reinforcing particle strengthening phase, and the proportion is 45vol of reinforcing particles in volume percentage .%, the rest is Al.

[0077] The specific microwave sintering preparation method of the particle reinforced aluminum matrix composite material of the present invention is:

[0078] (1) ball mill

[0079] For step-by-step ball milling, the 2059 alloy particles are first ball milled separately, with a ball-to-material ratio of 20:1; high-speed ball milling, with a speed of 250r / min; ball milling time of 8 hours, and a high ball-to-material ratio of 20:1 for Al particles; medium-speed ball milling, with a speed of 20:1 150r / min; ball milling time 20h. Then mix according to the formula ratio, add ethanol, the ball-to-material ratio is 2:1, and wet-mill and mix the powder in a planetary ball mill for 5 hours at a speed of 150r / min.

[0080] (2) Ultrasonic dispersion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com