Heterogeneous composite catalytic oxidation sewage advanced treatment method and system thereof

A technology of catalytic oxidation and advanced treatment, which is applied in the direction of oxidized water/sewage treatment, heterogeneous catalyst chemical elements, water/sewage treatment, etc. Problems such as the treatment of degraded substances, to achieve the effect of improving the reuse rate and catalytic effect, high production rate, and improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The preparation method of composite catalyst described in S2 comprises the steps:

[0089] S21, using an equal-volume immersion method, weighing transition metal nitrate and chloride salts according to the proportion, adding water or ethanol or other organic solvents to dissolve, and preparing a metal salt solution.

[0090] S22, adjusting the pH value of the metal salt solution to 11-13, stirring evenly, and standing still.

[0091] S23, take γ-Al 2 o 3 The ball is immersed in the above metal salt solution for 10-15 hours.

[0092] S24, drying the γ-Al 2 o 3 The ball is sintered at a high temperature, the sintering temperature is 300-500° C., and the holding time is 2-5 hours to obtain a composite catalyst.

[0093] The mass fraction ratio of ozone input amount to COD removal amount in S2 is 0.4-1.

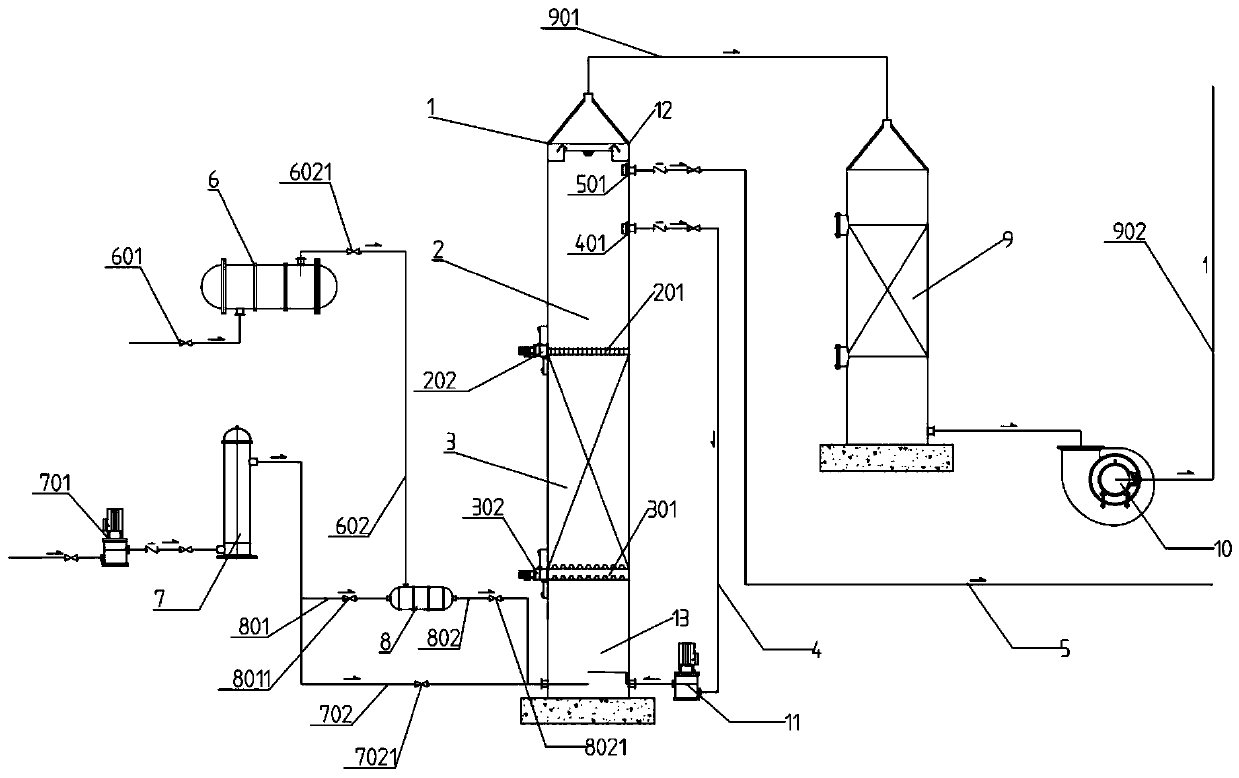

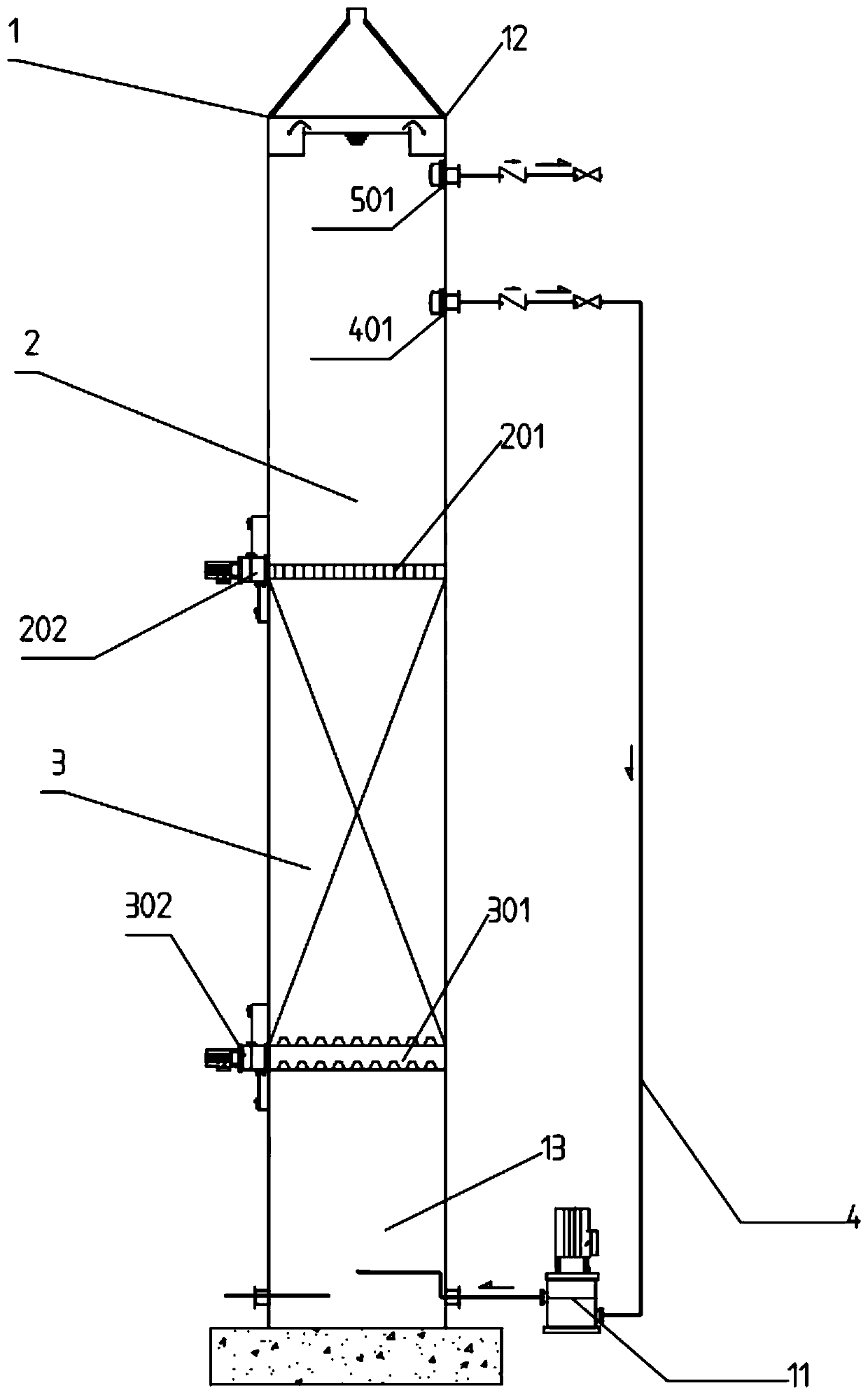

[0094] This embodiment also provides a heterogeneous composite catalytic oxidation sewage advanced treatment system for the above-mentioned heterogeneous composite c...

Embodiment 1

[0137] Utilize the processing method of the present invention to process certain hospital waste water, the COD concentration in the waste water is 210mg / L, adopt the method flow process of the present invention to process above-mentioned waste water, the catalyst carrier of selection is gamma-Al 2 o 3 , its active component is Mn-Ce-Cu, the weight ratio of each component of the catalyst is Mn:Ce:Cu=3:1:2, the flow rate of ozone is 1.0L / min, and the COD concentration in the wastewater after treatment is 15mg / L, the COD removal rate reached 92.86%.

Embodiment 2

[0139] Utilize the processing method of the present invention to process certain chemical factory waste water, the COD concentration in the waste water is 1500mg / L, the above-mentioned waste water adopts the method flow process described in the present invention to process, and the selected catalyst carrier is γ-Al 2 o 3 , its Mn-Ce-Co, the weight ratio of each component of catalyst is Mn:Ce:Co=5:2:3, the flow of ozone is 2.5L / min, and the COD concentration in the waste water after treatment is 30mg / L, COD removal rate reaches 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com