A kind of preparation method of cerium oxide particles for coating

A cerium oxide and particle technology, which is applied in the field of preparation of cerium oxide particles for coating, can solve the problems of difficult densification of cerium oxide, influence film quality, structural transformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing high-purity, high-density, low-sputter cerium oxide particles, comprising the steps of:

[0033] Weigh 5000 g of cerium oxide powder with a purity of ≥99.99%, add a certain amount of deionized water and granulate to obtain flaky cerium oxide, with a weight of 5.3 kg after granulation. The flaky cerium oxide is ground and crushed into fine particles, and the pretreated powder with a particle size of less than 0.1 mm is sieved through a standard sieve with an aperture of 0.1 mm, and loaded into two special rubber cylinders, with 863 g and 832.9 g of materials respectively, and then Placed in a cold isostatic press for molding, the molding pressure is 200Mpa, and the initial density of the two green bodies measured after taking out is 5.5g / cm 3 and 5.25g / cm 3 . Place the two blanks together in an intelligent box-type muffle furnace for high-temperature sintering. The sintering process is as follows: heat up to 400 degrees for 1 hour in 3 hours, hea...

Embodiment 2

[0035] Embodiment 2 (comparative example)

[0036] A method for preparing cerium oxide particles, comprising the steps of:

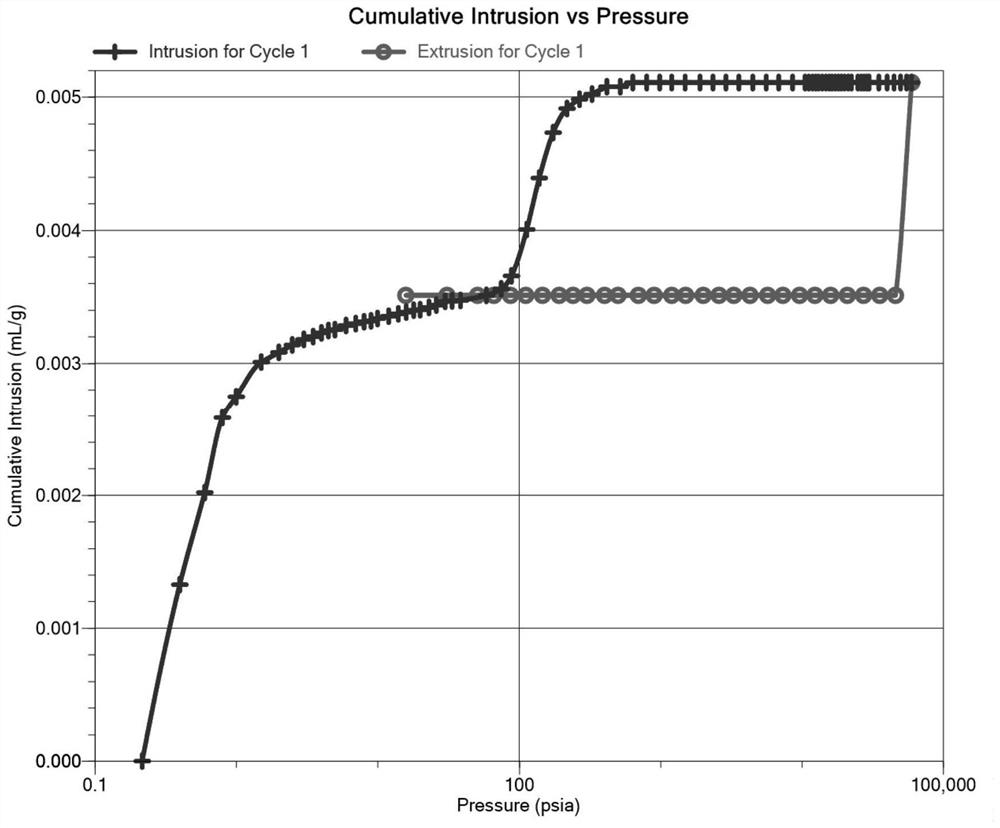

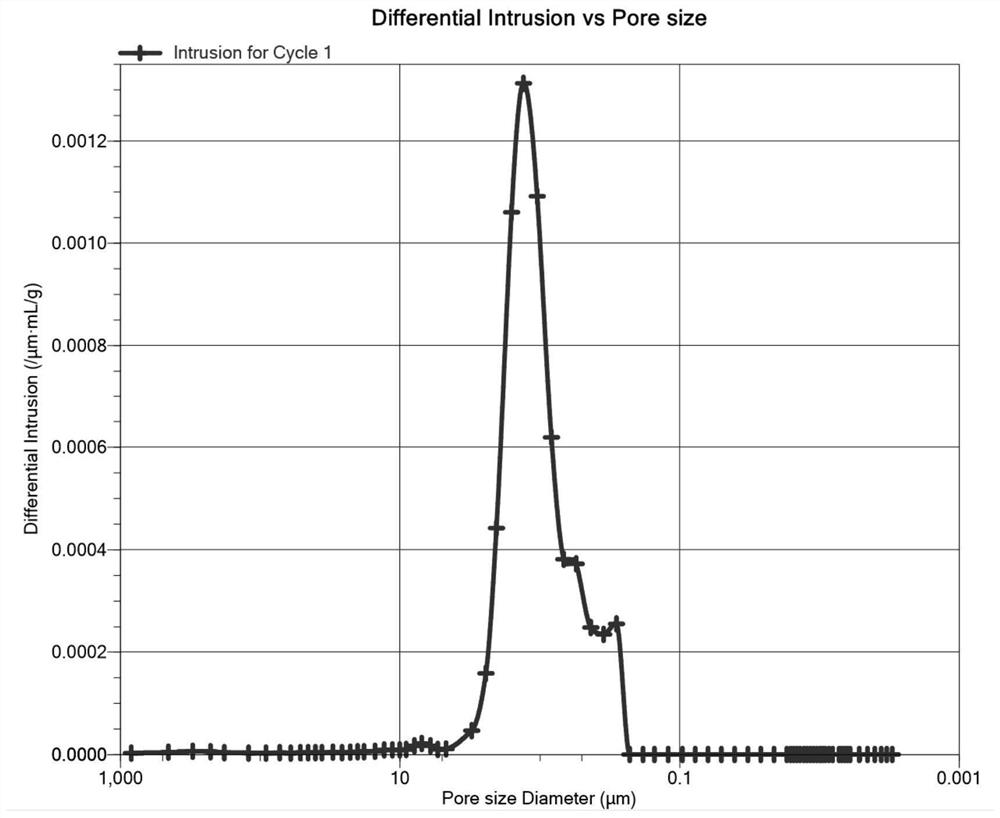

[0037] Weigh 5000g of cerium oxide powder with a purity ≥ 99.99%, add a certain amount of deionized water and granulate it into flakes, with a weight of 5.3kg after granulation. Grinding and crushing the formed flake cerium oxide, using a special standard sieve to screen out 3-6mm particles, and directly placing them in an intelligent box-type muffle furnace for high-temperature sintering. The sintering process is: heat up to 400 degrees for 2 hours and hold for 1 hour. 1 hour to 600 degrees for 1 hour, 3 hours for 1000 degrees for 1 hour, 3 hours for 1300 degrees for 3 hours. The highest sintering temperature is 1300°C, and the mercury intrusion analysis results are as follows image 3 As shown, the obtained cerium oxide particles are tested by mercury porosimetry and have a particle volume density of 5.95g / cm 3 , The relative density is 83.4%, the o...

Embodiment 3

[0038] Embodiment 3 (comparative example)

[0039] A method for preparing cerium oxide particles, comprising the steps of:

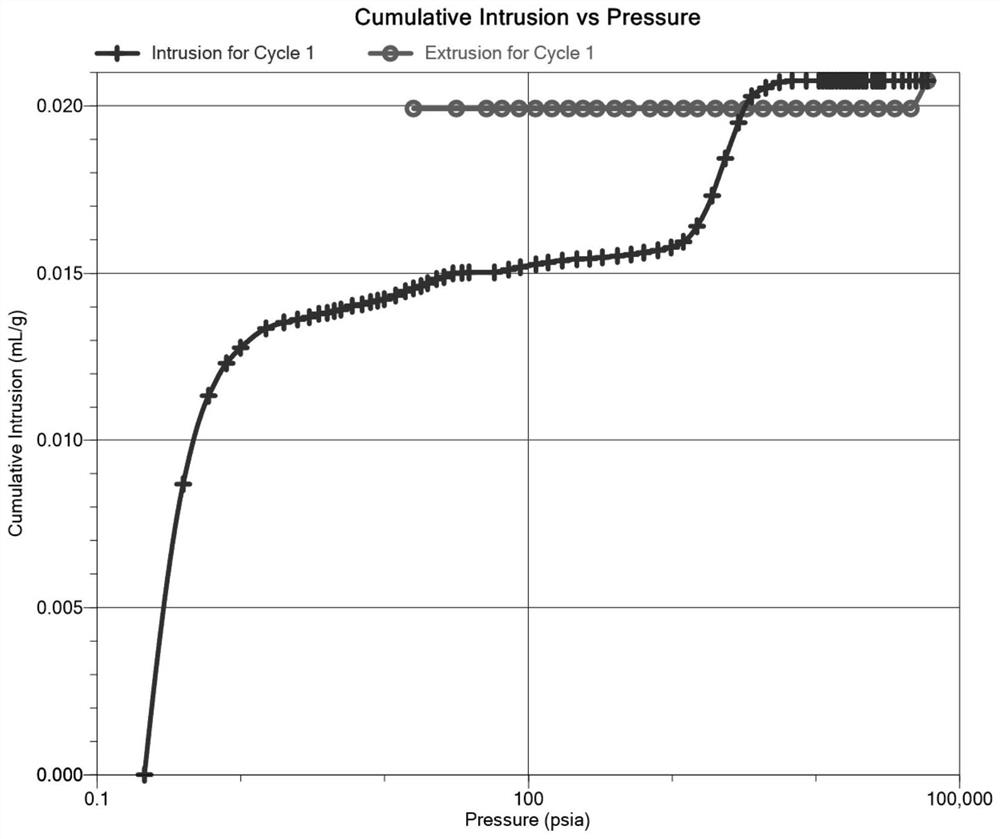

[0040] Weigh 5000 g of cerium oxide powder with a purity of ≥99.99%, add a certain amount of deionized water and granulate to obtain flaky cerium oxide, with a weight of 5.3 kg after granulation. The flaky cerium oxide is ground and broken into fine particles, and the pretreated powder with a particle size of less than 0.1mm is sieved through a standard sieve with a hole diameter of 0.1mm, and put into a special rubber cylinder with a charge of 860g, and then placed in a cold isostatic press Molded in the machine, the molding pressure is 200Mpa, and the initial density of the green body after taking out is 5.5g / cm 3 . Place the green body in an intelligent box-type muffle furnace for high-temperature sintering. The sintering process is as follows: heat up to 400 degrees for 1 hour for 2 hours, heat for 1 hour for 600 degrees for 1 hour, heat for 1 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com