Silicon carbide ceramic sucker and preparation method thereof

A silicon carbide ceramic and silicon carbide powder technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of easy deformation, poor temperature resistance, acid and alkali resistance, poor suction cup accuracy, etc. Good acid-base corrosion performance and small thermal deformation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

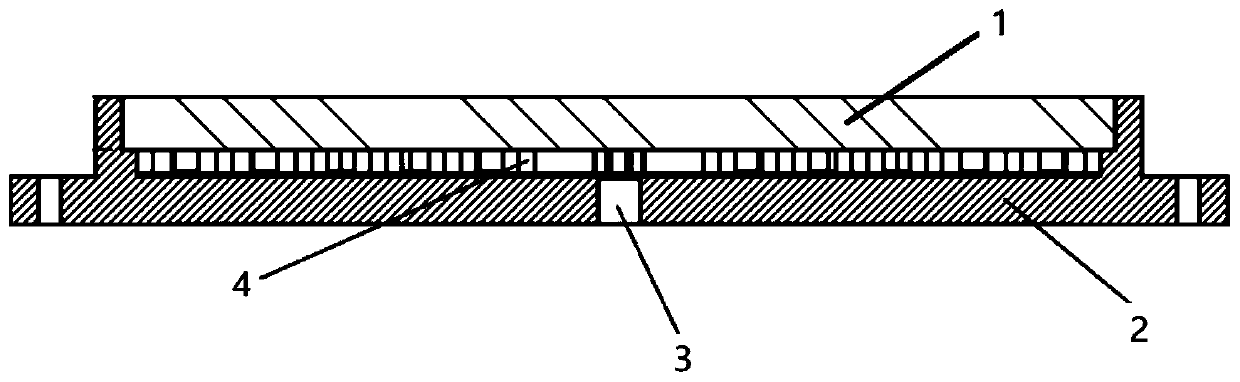

Image

Examples

preparation example Construction

[0042] Another embodiment of the present invention proposes a method for preparing a silicon carbide ceramic chuck, which includes:

[0043] (1) Preparation of ceramic base: mixing silicon carbide powder, carbon black powder, adhesive and water to obtain a dense silicon carbide ceramic slurry; making the dense silicon carbide ceramic slurry into a ceramic base green body; The ceramic base blank is sintered and precisely processed to obtain a dense silicon carbide ceramic base; wherein, the weight ratio of the silicon carbide powder, carbon black powder, binder and water is: 60-80:5-15: 3-6:10-25;

[0044] In this step, the silicon carbide ceramic base with complex vacuum channels and lightweight structure is prepared by molding method, isostatic pressing method, grouting method or gel injection molding method. The gel injection molding method is preferred, and the sintering temperature is 1500 -2200°C.

[0045](2) Preparation of the ceramic sucker body: mix silicon carbide p...

Embodiment 1

[0056] A method for preparing a silicon carbide ceramic sucker, which mainly includes the following steps:

[0057] (1) silicon carbide powder: 30 parts; carbon powder (ignition loss agent): 8 parts; alumina powder and quartz powder (bonding agent): 1 part; monomer and crosslinking agent: 1 part; and water: 60 parts were weighed in proportion, poured into a stirrer for stirring, and mixed for 12 hours to obtain a porous silicon carbide ceramic slurry;

[0058] (2) Pour 0.1 part of initiator ammonium persulfate into the porous silicon carbide ceramic slurry prepared in step (1), continue stirring and mixing for 30 minutes;

[0059] (3) Inject the ceramic slurry obtained in step (2) into a mold, heat to 50° C. and keep it warm for 2 hours to solidify the slurry and obtain a porous silicon carbide ceramic blank. After taking it out, dry it at room temperature for 48 hours;

[0060] (4) Put the dried porous silicon carbide ceramic blank into a muffle furnace, heat up to 1500°C, a...

Embodiment 2

[0070] A method for preparing a silicon carbide ceramic sucker, which mainly includes the following steps:

[0071] (1) Silicon carbide powder: 50 parts; Ignition loss agent carbon powder: 18 parts; Binder quartz powder: 1 part; Monomer and crosslinking agent: 2 parts, and water: 27 parts Weigh in proportion, pour into the stirrer, stirred and mixed for 12 hours to obtain porous silicon carbide ceramic slurry;

[0072] (2) Pour 0.1 part of initiator ammonium persulfate into the ceramic slurry prepared in step 1, continue to stir, and mix for 30 minutes;

[0073] (3) Inject the ceramic slurry obtained in step (2) into a mold, heat to 50° C. and keep it warm for 2 hours to solidify the slurry and obtain a porous silicon carbide ceramic blank. After taking it out, dry it at room temperature for 48 hours;

[0074] (4) Put the dried porous silicon carbide ceramic blank into a muffle furnace, heat up to 1300°C, and sinter to obtain porous silicon carbide ceramics. The sintered poro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com