Metal fluoride high-temperature phase change energy storage microcapsule, preparation method and application thereof

A high-temperature phase change and microcapsule technology, applied in the field of materials, can solve the problems that the shell temperature resistance is difficult to reach fluoride at the same time, the preparation process is complicated, and the research on coating is less. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

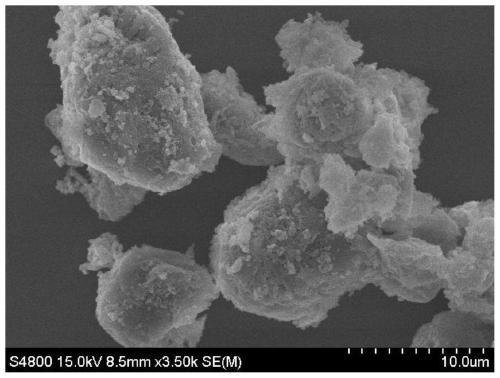

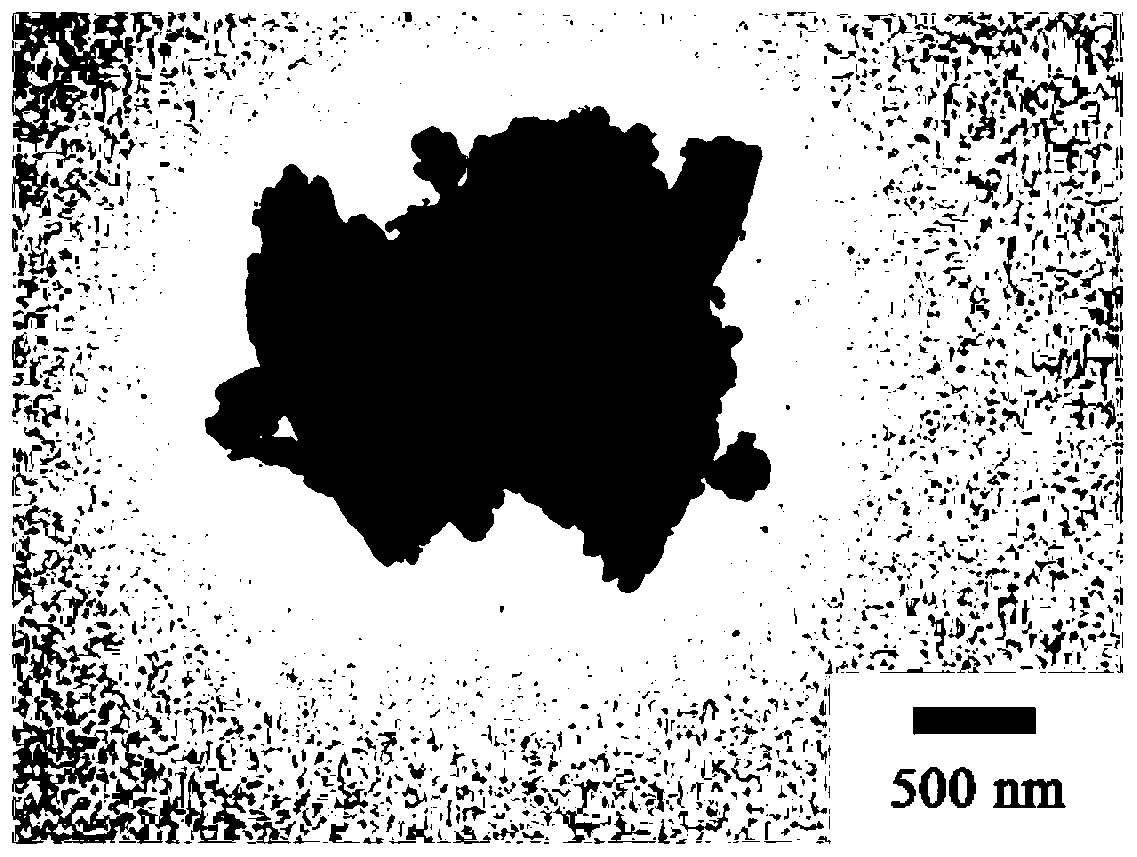

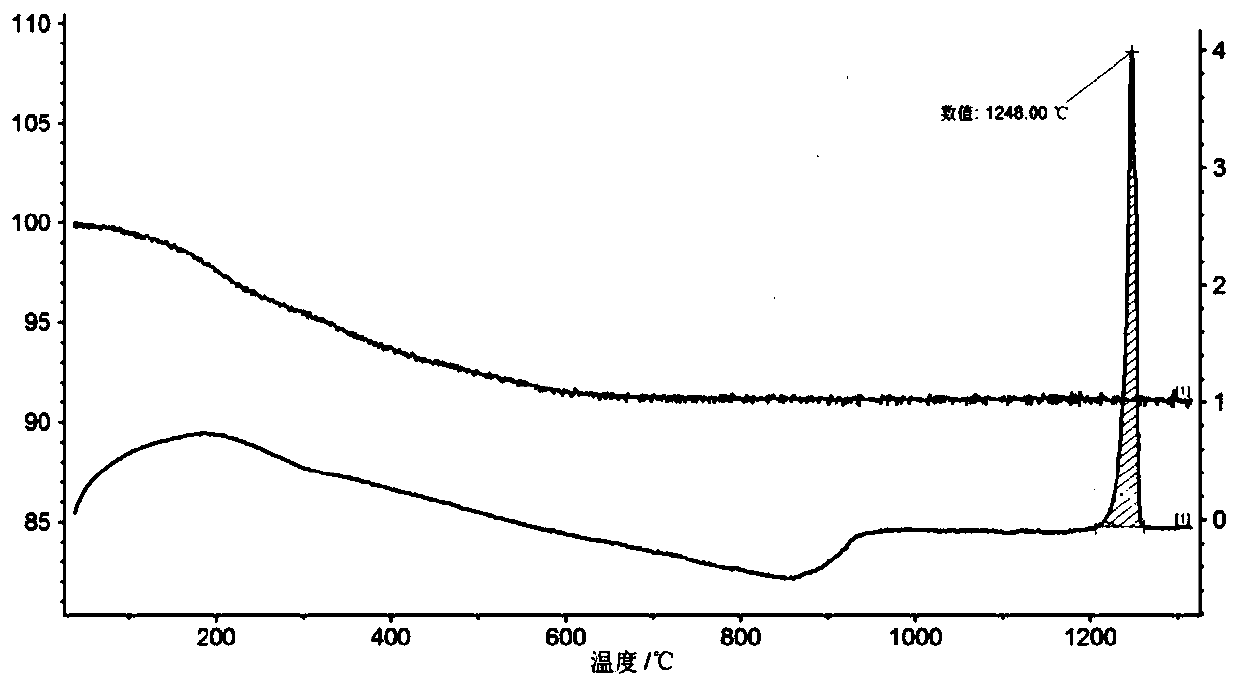

[0038] Embodiment 1, magnesium fluoride high-temperature phase change microcapsules

[0039] A fluoride high-temperature phase-change thermal storage microcapsule and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0040] Step 1, get 5g of magnesium fluoride and disperse it in a solution of 5g of phenolic resin dissolved in 25g of ethanol, in which magnesium fluoride does not dissolve, stir and disperse evenly;

[0041] Step 2, slowly adding 25g of deionized water to the reaction system to promote phase separation and deposition of the phenolic resin on the surface of the magnesium fluoride particles;

[0042] Step 3: Adjust the pH value of the solution to 1, and heat it for 1 hour in a water bath at 50°C and stirring at 300 r / min to promote the in-situ curing of the phenolic resin, so as to avoid the destruction of the shell structure of the microcapsules caused by the melting of the resin during the post-curing process; ...

Embodiment 2

[0046] Embodiment 2, lithium fluoride high temperature phase change microcapsules

[0047] A fluoride high-temperature phase-change thermal storage microcapsule and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0048] Step 1, take 10g of lithium fluoride and disperse it in a solution of 1g of phenolic resin dissolved in 10g of methanol, in which lithium fluoride does not dissolve, stir and disperse evenly;

[0049] Step 2, slowly adding 100 g of deionized water to the reaction system to promote phase separation and deposition of the phenolic resin onto the surface of the lithium fluoride particles;

[0050] Step 3: Adjust the pH value of the solution to 5, and heat it for 24 hours in a water bath at 95°C and stirring at 400 r / min to promote the in-situ curing of the phenolic resin, so as to avoid the destruction of the shell structure of the microcapsules caused by resin melting during the post-curing process;

[0051] ...

Embodiment 3

[0054] Embodiment 3, sodium fluoride high temperature phase change microcapsules

[0055] A fluoride high-temperature phase-change thermal storage microcapsule and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0056] Step 1, get 5g of sodium fluoride and disperse it in a solution of 5g of phenolic resin dissolved in 20g of propanol, in this solution sodium fluoride is insoluble, stir and disperse evenly;

[0057] Step 2, slowly adding 100 g of tetraethyl orthosilicate to the reaction system to impel the phase separation of the phenolic resin to deposit on the surface of the sodium fluoride particles;

[0058] Step 3: Adjust the pH value of the solution to 1, and heat it for 24 hours in a water bath at 50°C and stirring at 300 r / min to promote the in-situ curing of the phenolic resin, so as to avoid the destruction of the shell structure of the microcapsules caused by resin melting during the post-curing process;

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com