Titanium-aluminum-molybdenum alloy target material and preparing method thereof

A molybdenum alloy, titanium-aluminum technology, applied in the field of titanium-aluminum-molybdenum alloy target and its preparation, can solve the problems of relatively large difference, difficult to achieve large size, easy cracking in product processing, etc. , the effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

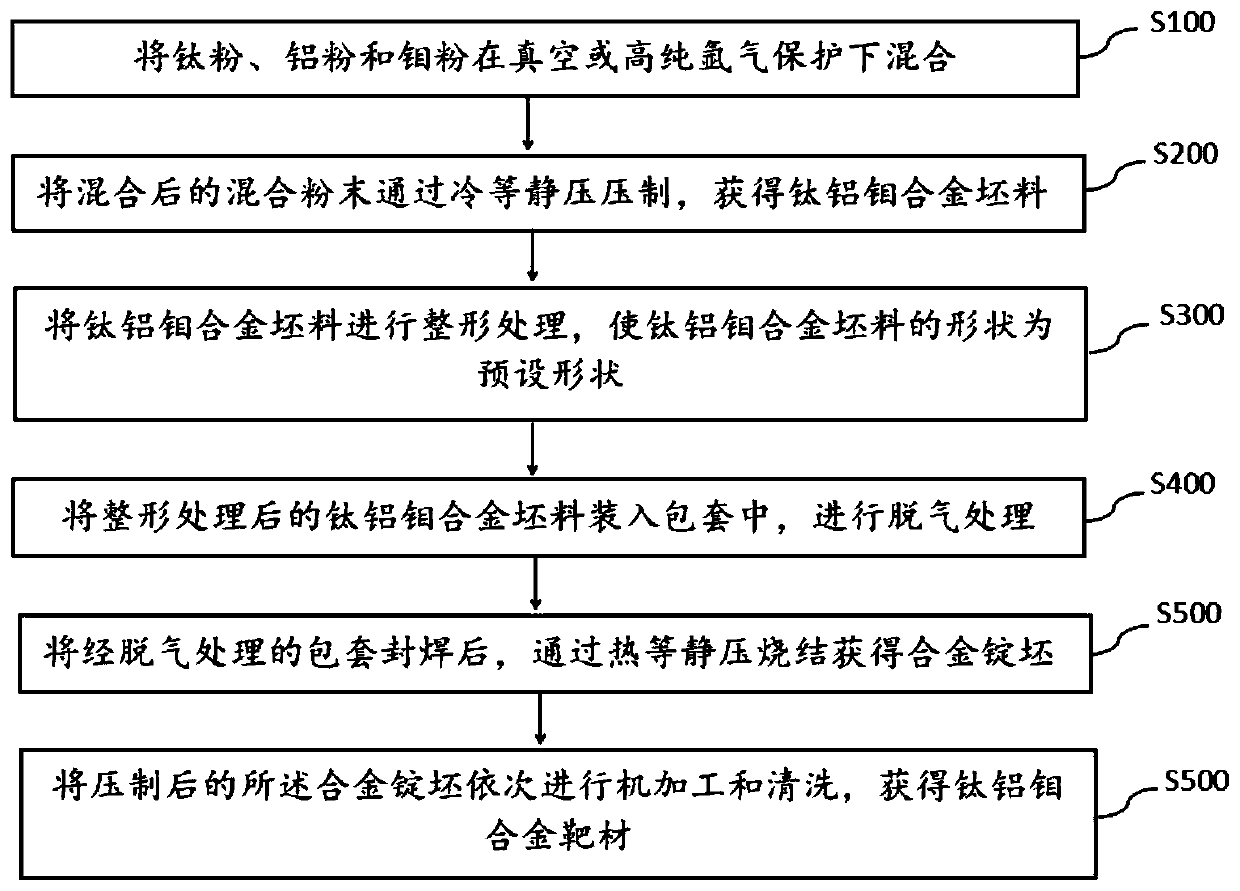

[0029] The second aspect of the present invention provides a method for preparing a titanium-aluminum-molybdenum alloy target, see figure 1 ,include:

[0030] S100. Titanium powder with a purity of 99.5% or more and an average particle size of 20-40um, aluminum powder with a purity of 99.5% or more and an average particle size of 10-30um, and a purity of 99.5% or more and an average particle size of 5-10um Put the molybdenum powder into a V-shaped mixer or a three-dimensional mixer, and mix for 4 to 6 hours under the protection of vacuum or high-purity argon.

[0031] S200. Put the mixed powder into a cold isostatic pressing mold, perform cold isostatic pressing under a pressure of 20-100 MPa, and hold the pressure for 10-30 minutes to obtain a titanium-aluminum-molybdenum alloy billet.

[0032] S300. Reshape the titanium-aluminum-molybdenum alloy blank by a lathe or milling machine, so that the shape of the titanium-aluminum-molybdenum alloy blank is a preset shape; wherein,...

Embodiment 1

[0039] The first aspect of this embodiment provides a titanium-aluminum-molybdenum alloy target, which comprises the following components in mass percentage: 20at% titanium, 60a% aluminum, and 20at% molybdenum.

[0040] The second aspect of this embodiment provides a method for preparing a titanium-aluminum-molybdenum alloy target, including the following steps:

[0041] (1) Put titanium powder with a purity of more than 99.5% and an average particle size of 30um, aluminum powder with a purity of more than 99.5% and an average particle size of 30um, and molybdenum powder with a purity of more than 99.5% and an average particle size of 6.8um into a three-dimensional mixer, and mixed for 4 hours under vacuum or high-purity argon protection.

[0042] (2) Put the mixed powder into a cold isostatic pressing mold, perform cold isostatic pressing under a pressure of 100 MPa, and hold the pressure for 10 minutes to obtain a titanium-aluminum-molybdenum alloy billet.

[0043] (3) The ...

Embodiment 2

[0050] The first aspect of this embodiment provides a titanium-aluminum-molybdenum alloy target, which comprises the following components in mass percentage: 38at% titanium, 50a% aluminum, and 12at% molybdenum.

[0051] The second aspect of this embodiment provides a method for preparing a titanium-aluminum-molybdenum alloy target, including the following steps:

[0052] (1) Put titanium powder with a purity of more than 99.5% and an average particle size of 35um, aluminum powder with a purity of more than 99.5% and an average particle size of 24um, and molybdenum powder with a purity of more than 99.5% and an average particle size of 8um In a V-type blender or a three-dimensional blender, mix for 5 hours under vacuum or high-purity argon protection.

[0053] (2) Put the mixed powder into a cold isostatic pressing mold, perform cold isostatic pressing under a pressure of 80 MPa, and hold the pressure for 20 minutes to obtain a titanium-aluminum-molybdenum alloy billet.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com