High-efficiency flexible laminated thin-film solar cell and preparation method thereof

A solar cell and high-efficiency technology, applied in the field of solar cells, can solve the problems of lack of low-bandgap polymers, backward performance of tandem devices, and limited application range, etc., to achieve the effects of increasing hole concentration, optimizing efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

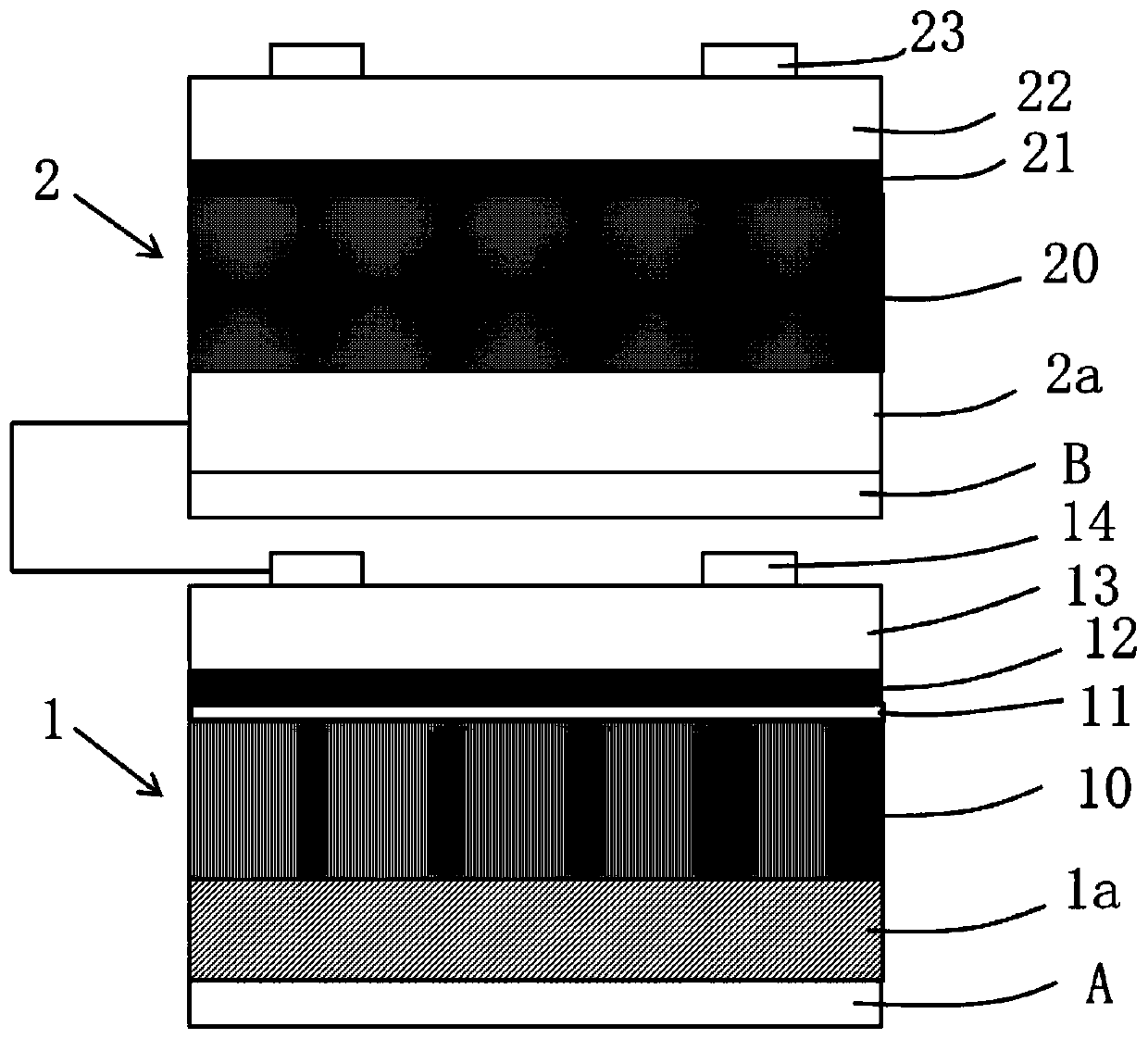

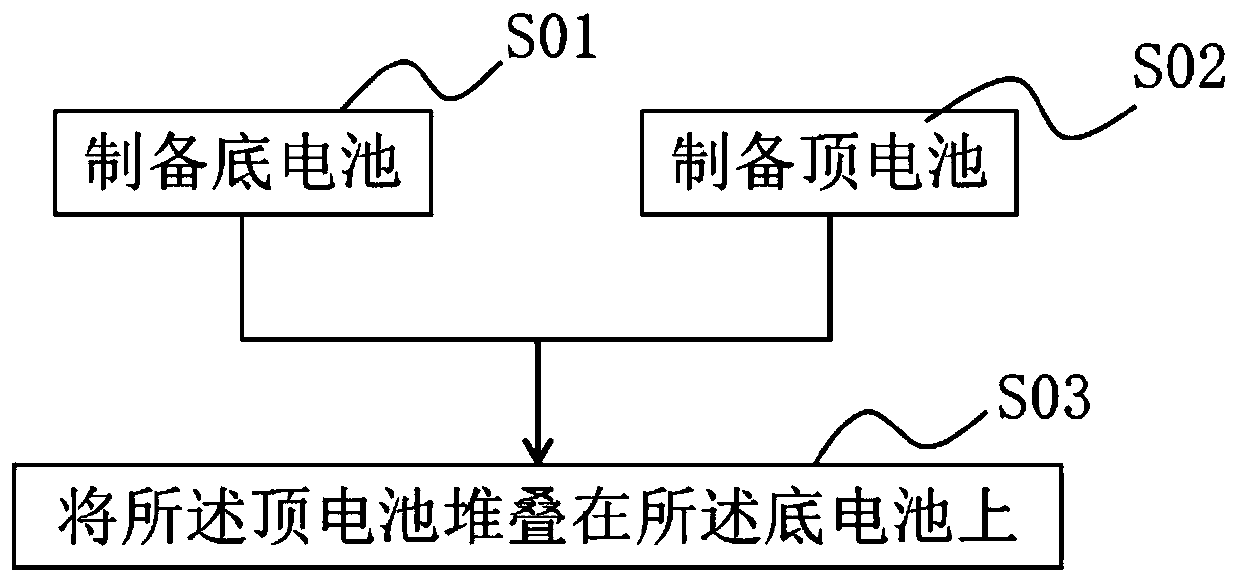

[0057] combine figure 1 and figure 2 As shown, the present invention provides a high-efficiency flexible laminated thin-film solar cell and a preparation method thereof, the preparation method comprising:

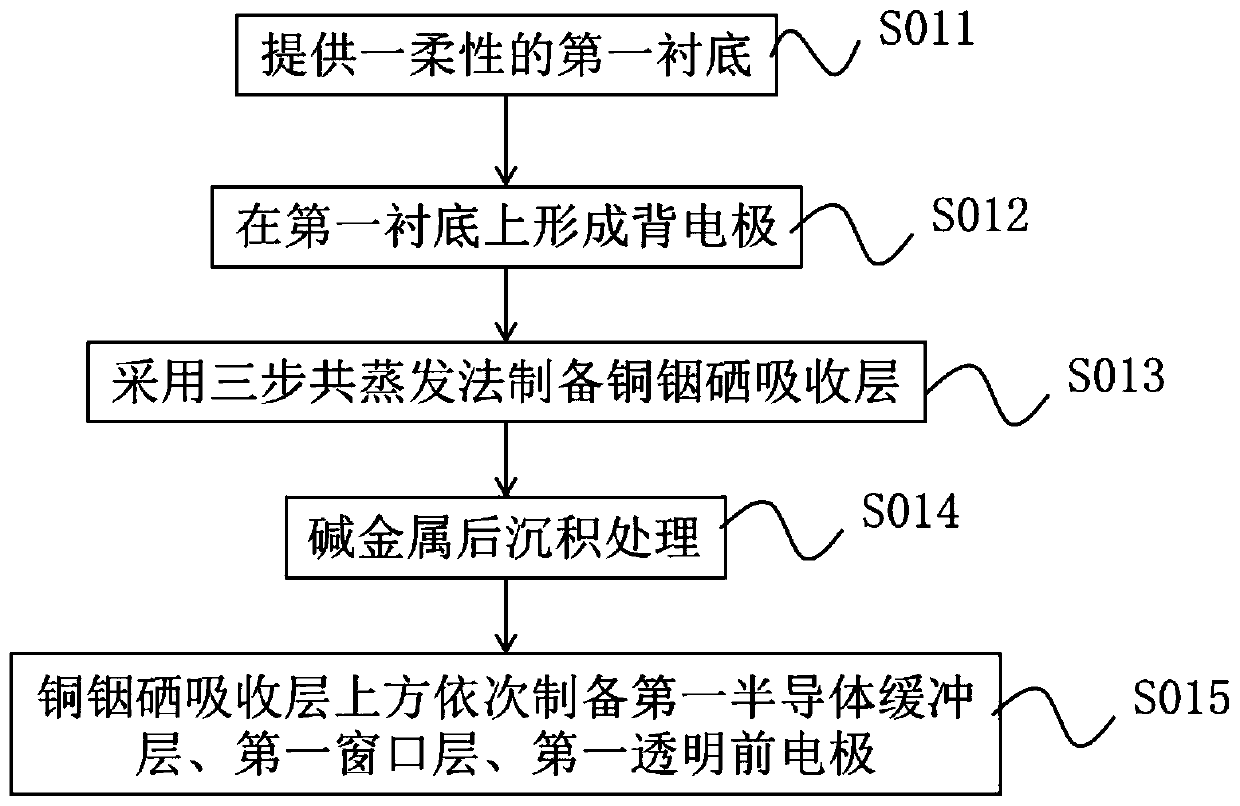

[0058] S01, preparing a bottom cell 1, the P-type semiconductor absorber layer of the bottom cell 1 is a copper indium selenium absorber layer 10;

[0059] S02, preparing the top cell 2, the bandgap of the top cell 2 is wider than that of the bottom cell 1;

[0060] S03, using a mechanical stacking method to stack the top cell 2 on the bottom cell 1 .

[0061] In this embodiment, the narrow-bandgap bottom cell 1 and the wide-bandgap top cell 2 can be fabricated independently, and then formed in a 4-terminal stacked structure using a mechanical stacking method. Not only can the band gap be flexibly selected to distribute light absorption, but also the It requires current matching and is easier to prepare. After the top cell 2 is stacked on the bottom cell 1, a top ohmic...

Embodiment 2

[0091] Different from Example 1, the top cell 2 of the stacked thin film solar cell of this embodiment can be a perovskite (perovskite) cell or a cadmium telluride (CdTe) cell, and the semiconductor absorber layer corresponding to the top cell 2 is a perovskite absorber layer or CdTe. Using a CIS flexible cell with a bandgap of about 1.0eV as the bottom cell 1, combined with a wide bandgap flexible perovskite and a cadmium telluride thin-film solar front cell with a bandgap of about 1.7eV, the efficiency can be as high as 30%. double-junction tandem flexible solar cells.

[0092] Such as Figure 4 Shown is a schematic diagram of the structure of the perovskite top cell.

[0093] The perovskite top cell 2 is mainly composed of a photoanode 201 , an electron transport layer (ETL) 202 , a perovskite absorption layer 203 , a hole transport layer (HTL) 204 , and a back electrode 205 . The photoanode 201 is generally a fluorine-doped oxide (FTO), and the back electrode 205 is gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com