Waterproof gypsum-based caulking paste

A gypsum-based, gypsum technology, applied in the field of building materials, can solve the problems of non-waterproof, affecting construction quality and decorative aesthetics, joint deformation, etc., to improve waterproof performance, good adhesion, and prevent water absorption deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

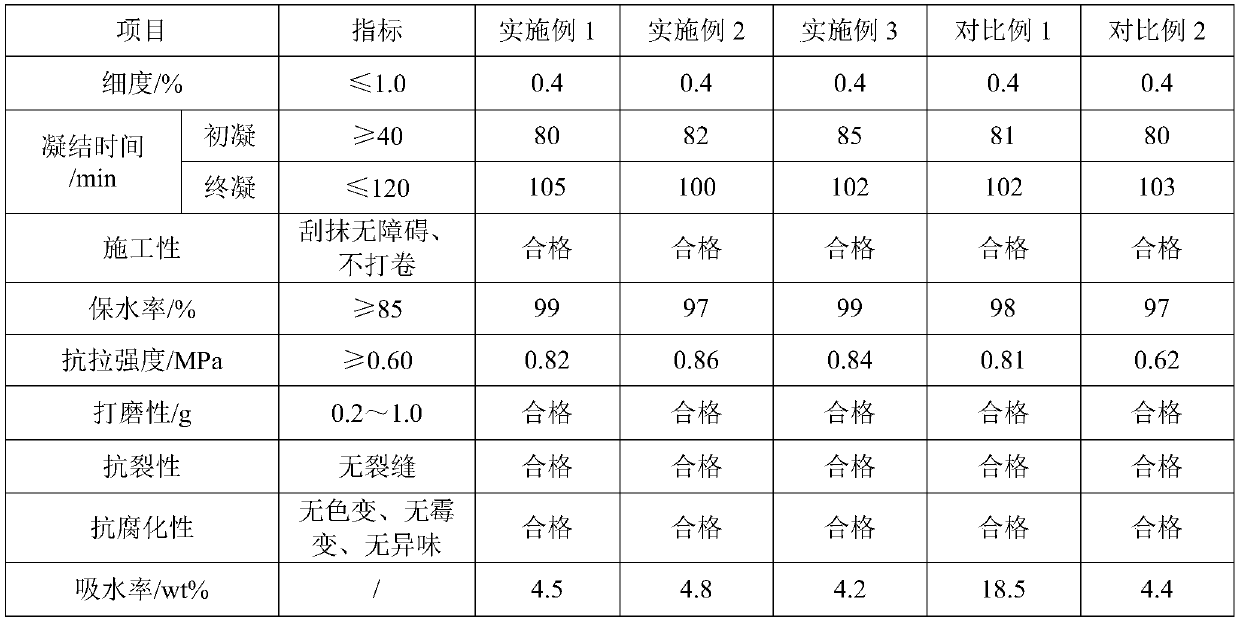

Examples

Embodiment 1

[0032] A waterproof gypsum-based caulking paste, in parts by weight, the composition includes 900 parts of gypsum, 11 parts of bamboo fibers with a length of 15mm, 0.3 parts of sodium citrate, 3 parts of cellulose ether, 5 parts of redispersible latex powder, 1 Parts of starch ether, 4 parts of polydimethylsiloxane grafted styrene-butyl acrylate-silane coupling agent emulsion copolymer and 500 parts of water.

[0033] The preparation method of the polydimethylsiloxane-grafted styrene-butyl acrylate-silane coupling agent emulsion copolymer comprises the steps:

[0034] (1) Dissolve alkylphenol polyoxyethylene ether and sodium bicarbonate in water, stir until completely dissolved to obtain bottom liquid A, the mass ratio of alkylphenol polyoxyethylene ether, sodium bicarbonate and water is 4:1: 65;

[0035] (2) Dissolve the alkylphenol polyoxyethylene ether in water, the mass ratio of the alkylphenol polyoxyethylene ether and water to the mass ratio in step (1) is 1.5:1, stir u...

Embodiment 2

[0040]A waterproof gypsum-based caulking paste, in parts by weight, the composition includes 800 parts of gypsum, 10 parts of wood fibers with a length of 10mm, 5 parts of cotton fibers with a length of 10mm, 0.2 parts of sodium polyphosphate, and 2 parts of carboxymethyl Cellulose, 1 part of redispersible latex powder, 0.5 part of starch ether, 3 parts of polydimethylsiloxane-grafted styrene-butyl acrylate-silane coupling agent emulsion copolymer and 400 parts of water.

[0041] The preparation method of the polydimethylsiloxane-grafted styrene-butyl acrylate-silane coupling agent emulsion copolymer comprises the steps:

[0042] (1) Dissolve alkylphenol polyoxyethylene ether and sodium bicarbonate in water, stir until completely dissolved to obtain bottom liquid A, the mass ratio of alkylphenol polyoxyethylene ether, sodium bicarbonate and water is 2:1: 60;

[0043] (2) Dissolve the alkylphenol polyoxyethylene ether with the same quality as in step (1) in the water with the ...

Embodiment 3

[0048] A waterproof gypsum-based caulking paste, in parts by weight, the composition includes 1000 parts of gypsum, 10 parts of bamboo fibers with a length of 20mm, 0.5 parts of sodium citrate, 4 parts of polyacrylamide, 8 parts of redispersible latex powder, and 1.5 parts of Parts of starch ether, 5 parts of polydimethylsiloxane grafted styrene-butyl acrylate-silane coupling agent emulsion copolymer and 800 parts of water.

[0049] The preparation method of the polydimethylsiloxane-grafted styrene-butyl acrylate-silane coupling agent emulsion copolymer comprises the steps:

[0050] (1) Dissolve alkylphenol polyoxyethylene ether and sodium bicarbonate in water, stir until completely dissolved to obtain bottom liquid A, the mass ratio of alkylphenol polyoxyethylene ether, sodium bicarbonate and water is 6:1: 70;

[0051] (2) Dissolve the alkylphenol polyoxyethylene ether in water, the mass ratio of the alkylphenol polyoxyethylene ether and water to the mass ratio in step (1) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com