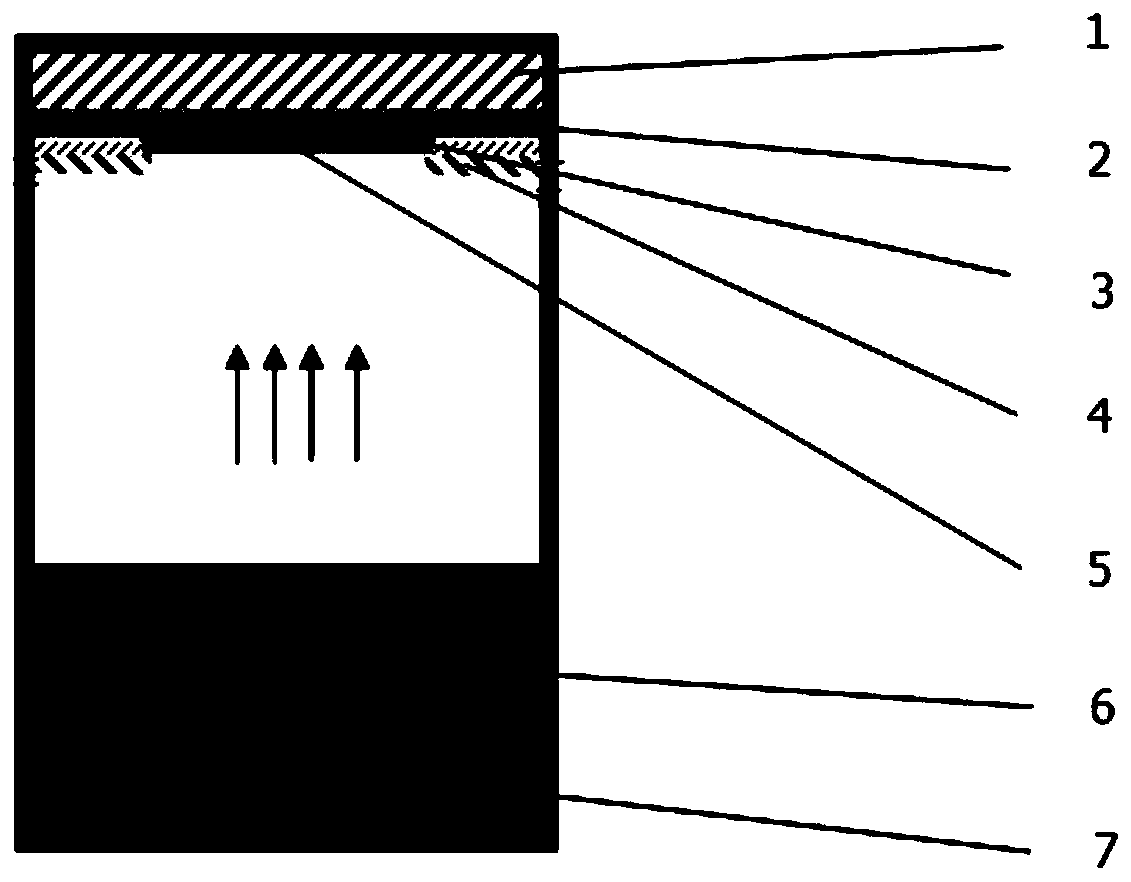

Graphite crucible device for silicon carbide crystal growth and single crystal growth method thereof

A technology of graphite crucible and crystal growth, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc. It can solve the problems of increasing wafer cost and increasing annealing process, and achieves the effect of reducing temperature gradient and low stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] A method for growing a low-stress silicon carbide single crystal, the specific preparation steps are:

[0028] Step 1. Put the silicon carbide raw material with a purity of 99.99% into the graphite crucible, place the growth side of the seed crystal coated with carbon film on the back on the circular step of the lower layer of the graphite crucible cover, and cover it with a high-purity glass with a thickness of 10 mm. Graphite felt insulation layer, the upper layer of the graphite crucible cover and the lower layer of the graphite crucible cover are screwed tightly, and then the lower layer of the graphite crucible cover is screwed tightly with the graphite crucible cavity;

[0029] Step 2, putting the sealed graphite crucible into the crystal growth furnace, sealing the crystal growth furnace, and evacuating;

[0030] Step 3. Using the physical vapor transport method to grow silicon carbide crystals, the crystal growth temperature is 2350°C, the substrate area tempera...

Embodiment 2

[0033] A method for growing a low-stress silicon carbide single crystal, the specific preparation steps are:

[0034] Step 1. Put the silicon carbide raw material with a purity of 99.99% into the graphite crucible, place the growth side of the seed crystal coated with carbon film on the back on the circular step of the lower layer of the graphite crucible cover, and cover it with a high-purity glass with a thickness of 15 mm. Graphite felt insulation layer, the upper layer of the graphite crucible cover and the lower layer of the graphite crucible cover are screwed tightly, and then the lower layer of the graphite crucible cover is screwed tightly with the graphite crucible cavity;

[0035] Step 2, putting the sealed graphite crucible into the crystal growth furnace, sealing the crystal growth furnace, and evacuating;

[0036] Step 3. Using the physical vapor transport method to grow silicon carbide crystals, the crystal growth temperature is 2400°C, the substrate area tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com