A kind of counter-beating process of stone with insulation board

A technology of thermal insulation board and stone, applied in the directions of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of cracking, hardness and brittleness, pedestrian impact, etc., and improve the aging resistance. , improve safety performance, improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

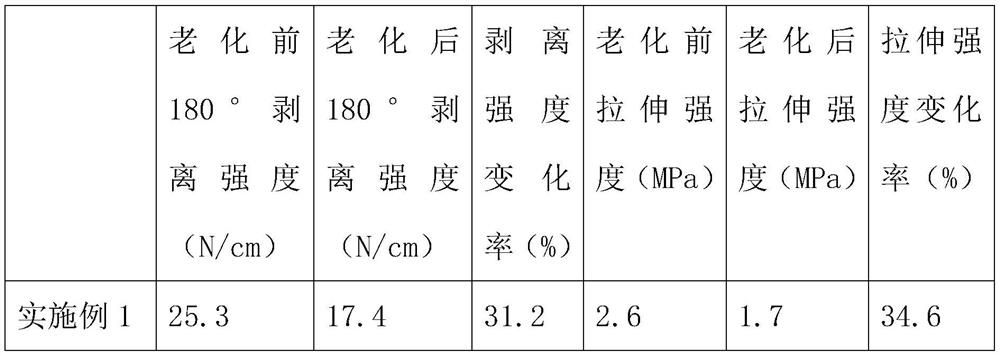

Embodiment 1

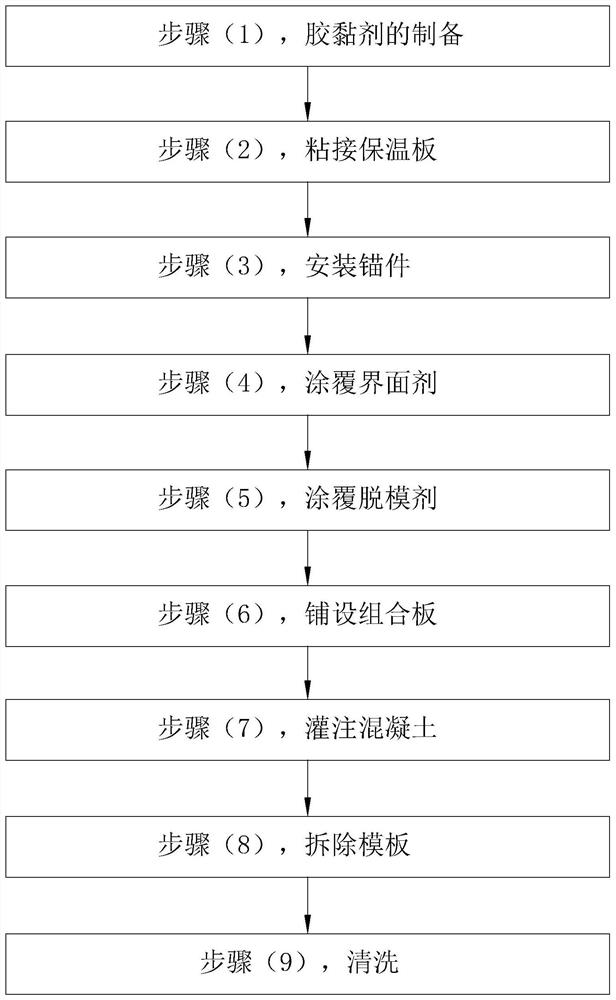

[0068] refer to figure 1 , which is a flow process of a stone anti-beating process with an insulation board added to the present invention, comprising the following steps:

[0069] Step (1), the preparation of adhesive, is as follows:

[0070] Add 120kg of epoxy acrylic resin to a 200L stirred tank, stir at a speed of 250r / min, add 10kg of thickener, 25kg of filler, 3kg of polyvinyl alcohol, 2kg of methyl hexahydrophthalic anhydride and 0.4kg of bilirubin while stirring , Stir and mix evenly to obtain the adhesive.

[0071] In this embodiment, the epoxy acrylic resin of Beijing Gaomeng New Materials Co., Ltd. is used.

[0072] In this embodiment, the filler is uniformly mixed with 9kg of calcium carbonate, 12kg of titanium dioxide and 4kg of zinc oxide.

[0073] Step (2), bonding the insulation board, is as follows:

[0074] The adhesive prepared in step (1) is evenly coated on the back of the stone board, and then the insulation board with the same size as the stone board...

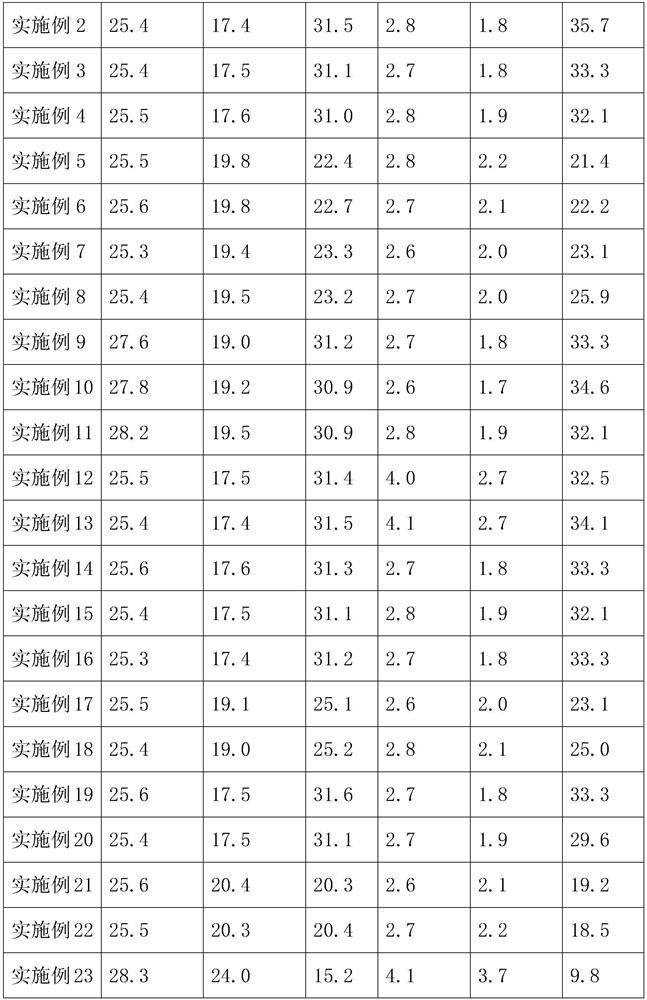

Embodiment 2

[0090] The difference with embodiment 1 is:

[0091] The consumption of each component that adds in the step (1) is as follows:

[0092] 125kg of epoxy acrylic resin; 5kg of thickener; 30kg of filler; 1kg of polyvinyl alcohol; 1kg of methyl hexahydrophthalic anhydride; 0.3kg of bilirubin.

[0093] Among them, the filler is uniformly mixed with 16kg of calcium carbonate, 4kg of titanium dioxide and 10kg of zinc oxide.

Embodiment 3

[0095] The difference with embodiment 1 is:

[0096] The consumption of each component that adds in the step (1) is as follows:

[0097] 130kg of epoxy acrylic resin; 7.5kg of thickener; 20kg of filler; 2kg of polyvinyl alcohol; 1.5kg of methyl hexahydrophthalic anhydride; 0.5kg of bilirubin.

[0098] Among them, the filler is uniformly mixed with 8kg calcium carbonate, 9kg titanium dioxide and 3kg zinc oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com