Protein-EGCG composite nanoparticle and antioxidant Pickering high internal phase emulsion

A technology of composite nanoparticle and protein solution, which is applied in the direction of emulsion delivery, anti-inflammatory agent, anti-toxic agent, etc. It can solve the problems of difficult slow-release targeting effect, high oil volume, difficult absorption, etc., and achieve superior antioxidant properties , Nutrient-rich, anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of nano particle, its preparation method comprises the following steps:

[0044] 1) Disperse 5 g of soybean β-conglycinin powder in 100 g of distilled water, stir at room temperature for 2 h, then add 1 drop of 0.08% sodium azide solution (to prevent the growth of microorganisms) with a concentration of 0.2 mol / L HCl solution and NaOH solution with a concentration of 0.2mol / L to adjust the pH of the solution to 7, stir for 2 hours, place in a refrigerator at 4°C overnight, then take it out from the refrigerator and return to room temperature, and centrifuge (8000rpm, 15min) to remove insoluble impurities to obtain A protein solution with a concentration of 5wt%;

[0045] 2) Disperse 0.4 g of EGCG powder in 20 g of distilled water, stir at room temperature for 2 h, and then place it in a refrigerator at 4° C. overnight to obtain an EGCG solution with a concentration of 2 wt %;

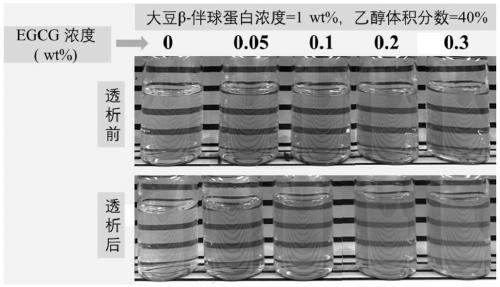

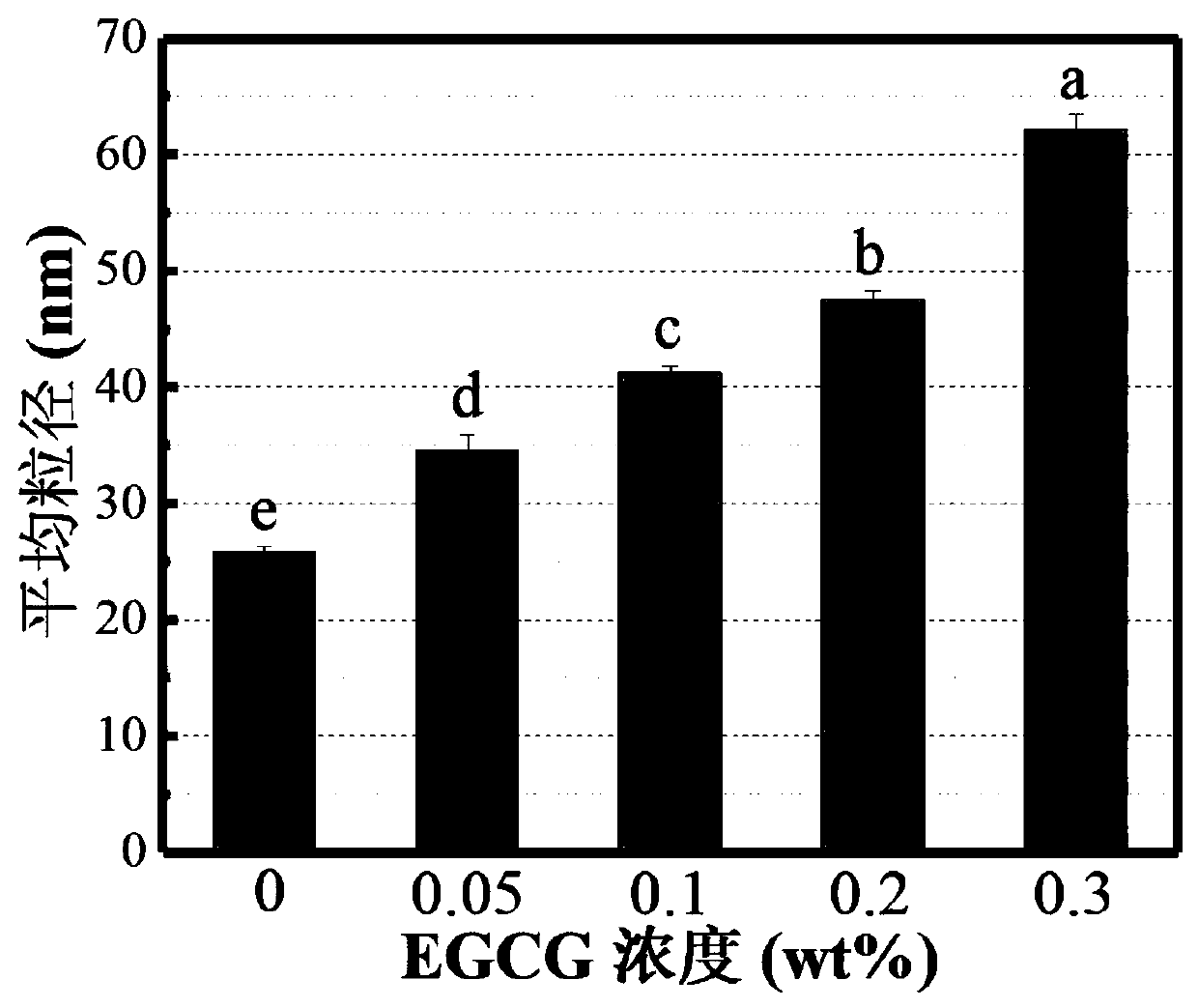

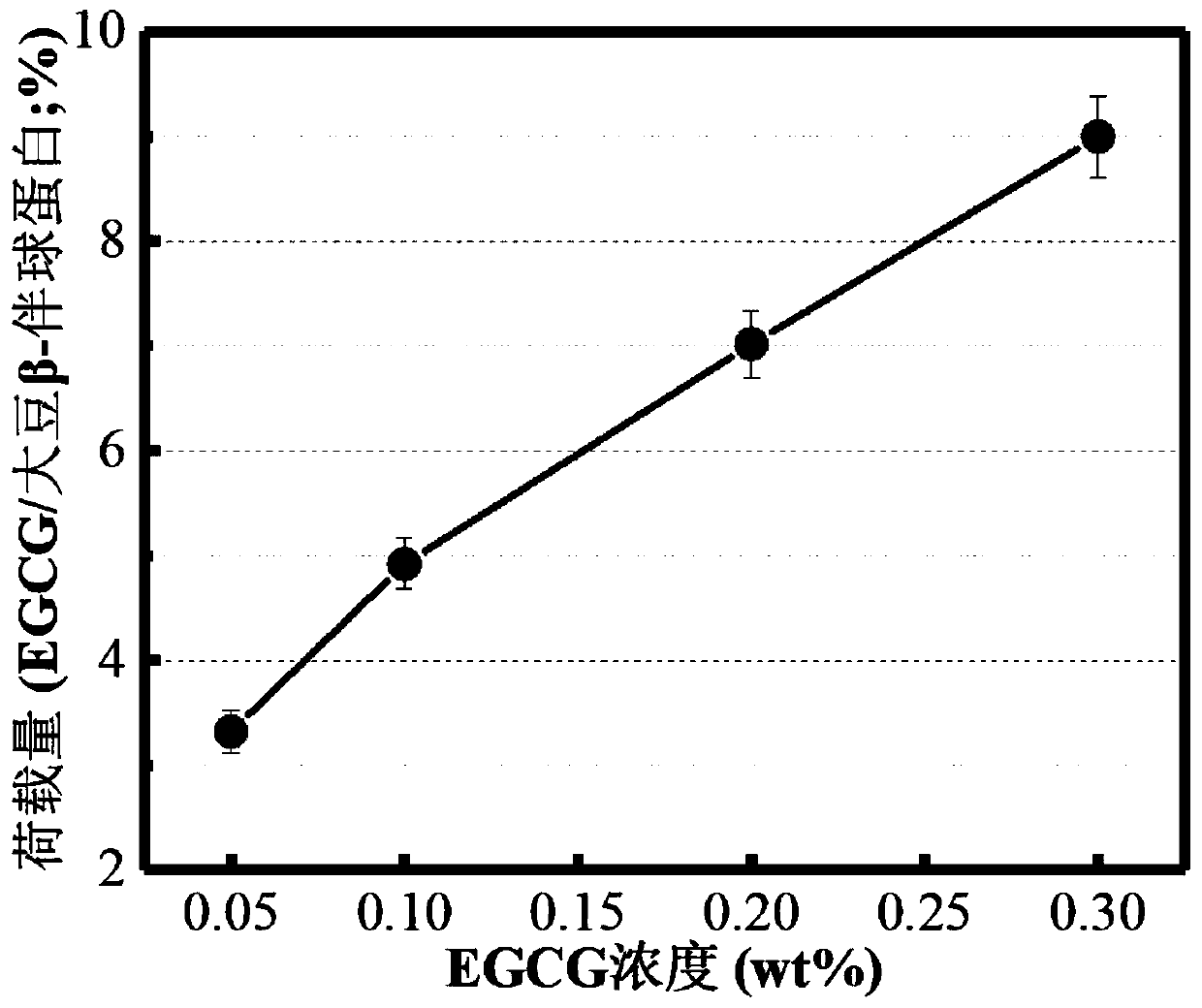

[0046]3) Take out 5 high-foot beakers with a capacity of 50mL and number them No. 1, ...

Embodiment 2

[0057] A kind of Pickering high internal phase emulsion, its preparation method comprises the following steps:

[0058] The protein particle solution of sample No. 1 in Example 1 and the protein-EGCG composite nanoparticle solution of samples No. 2 to No. 5 were mixed with linseed oil at a volume ratio of 1:4 and added to a homogenizer, and homogenized at 5000 rpm for 1 min to obtain Pickering high internal phase emulsion (the Pickering high internal phase emulsion corresponding to sample No. 1 does not have anti-oxidation function, and the Pickering high internal phase emulsion corresponding to samples No. 2 to 5 has anti-oxidation function).

[0059] Performance Testing:

[0060] The appearance picture and optical microscope picture of Pickering high internal phase emulsion Figure 5 shown.

[0061] The change of elastic modulus (G′, solid) and viscous modulus (G″, hollow) of Pickering high internal phase emulsion with frequency is shown in the figure Image 6 shown.

[...

Embodiment 3

[0070] Referring to the method of Example 2, the dispersed phase linseed oil was replaced by n-dodecane dissolved with 0.003 wt% β-carotene, and then the Pickering high internal phase emulsion was prepared.

[0071] Performance Testing:

[0072] The appearance of Pickering high internal phase emulsion after heat treatment (stored in 70°C electric thermostat for 18h) is as follows Figure 10 As shown, the retention rate of β-carotene is shown in Figure 11 Shown (a to f in the figure are marked for significant differences).

[0073] Depend on Figure 10 and Figure 11 It can be seen that after storage at 70°C for 18 hours, the stable high internal phase emulsion of No. 1 (without EGCG) particles, the stable high internal phase emulsion of No. 2, No. 3, No. 4, and No. 5 particles (protein-EGCG composite nanoparticles) , Tween 20 (2.0wt%) stable high internal phase emulsion, the beta-carotene retention rate in equal volume dispersion liquid n-dodecane is respectively 88.8%, 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com