Hollow plate ceramic membrane and preparation method thereof

A technology of ceramic membrane and flat membrane, applied in the field of preparation of hollow flat ceramic membrane, can solve problems such as insufficient service life of organic membranes, and achieve the effects of extending service life, high mechanical strength and reducing cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

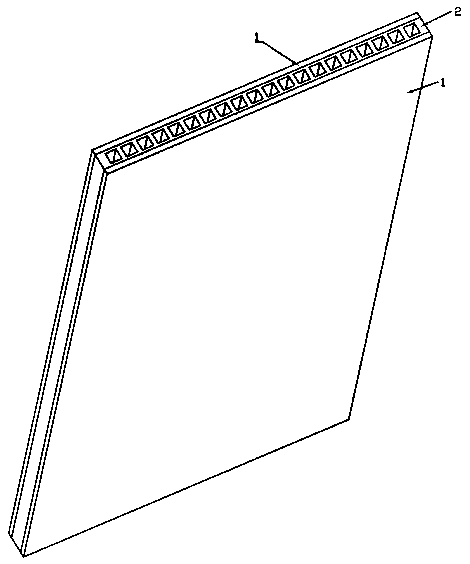

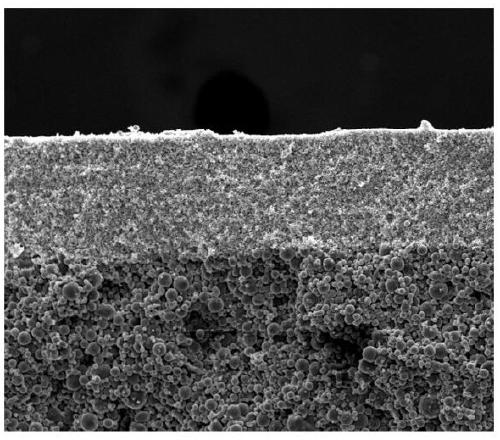

[0037] Hollow flat ceramic membrane, its structure is as attached figure 1 As shown, the structure includes a microporous membrane 1 and a supporting body 2 . The microporous membrane 1 and the supporting body 2 are processed from spherical alumina production waste as the main raw material.

[0038] The support body 2 is a hollow thin plate structure with square through-holes. The size of the square holes is 3~5*3~5mm, the wall thickness of the holes is 1.5mm, the porosity is 30~50%, and the pore size distribution is 0.5~5μm.

[0039]The microporous membrane 1 is integrally attached to both sides of the support body 2 after sintering, with a porosity of 50-60% and a pore size distribution of 0.01-0.5 μm.

Embodiment 2

[0041] A method for preparing a hollow flat ceramic membrane, the steps comprising:

[0042] S1. Preparation of support body with spherical alumina: Spherical alumina waste is hydrocyclone sieved to obtain 3-50 μm materials, and shaped by a ball mill. After shaping, the D50 particle size is D1, and the value of D1 is in [5, 20] . D1=3μm in this embodiment;

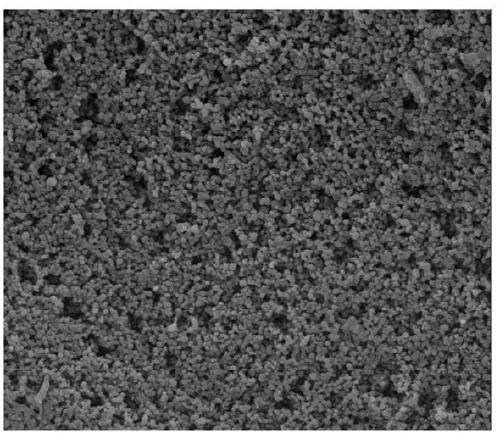

[0043] The microporous membrane is prepared from spherical alumina: Spherical alumina waste is hydrocyclone sieved to obtain materials with a thickness of 3 to 10 μm, and shaped by a ball mill. After shaping, the D50 particle size is D2, and the value of D2 is in [0.3, 3]. D2=0.3μm in this embodiment;

[0044] S2. Preparation of support body: In parts by weight, the raw materials of support body include 60 parts of ceramic aggregate, 5 parts of 0.5 μm starch, 1 part of methyl cellulose, 1 part of polyethylene glycol, and 10 parts of water. The ceramic aggregate includes The support body uses 78 parts of spherical alumin...

Embodiment 4

[0072] A method for preparing a hollow flat ceramic membrane, the steps comprising:

[0073] S1. Preparation of support body with spherical alumina: air cyclone sieving of spherical alumina waste to obtain 3-50 μm materials, and ball mill shaping. After shaping, the D50 particle size is D1, and the value of D1 is in [5, 20] . In this embodiment, D1=15μm;

[0074] Preparation of microporous membrane with spherical alumina: Spherical alumina waste is screened by air cyclone and hydrocyclone to obtain materials with a thickness of 3-10 μm, and shaped by a ball mill. After shaping, the D50 particle size is D2, and the value of D2 is [0.3 , 3]. D2=3μm in this embodiment;

[0075] S2. Preparation of support body: In parts by weight, the raw materials of support body include 76 parts of ceramic aggregate, 13 parts of 1 μm graphite powder, 8 parts of polyacrylamide, 3 parts of polyethylene glycol, and 16 parts of water. The body uses 91 parts of spherical alumina, 7 parts of magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com